A Guide to Precision Machining Techniques for Improved Accuracy and Precision

By:Admin

Founded in [year], Honing In Machining has grown from a small machine shop to a state-of-the-art facility with a team of highly skilled engineers and machinists. The company's commitment to investing in the latest technology and equipment has allowed it to stay ahead of the competition and offer its customers the most advanced manufacturing solutions available.

One of the key capabilities that sets Honing In Machining apart from its competitors is its honing services. Honing is a precision machining process that uses abrasive stones to remove small amounts of material from the interior of a part in order to achieve a precise size and surface finish. This process is crucial for achieving the tight tolerances and smooth finishes that many industries require, and Honing In Machining has perfected the art of honing over the years.

The company's honing services are ideal for a variety of applications, including hydraulic cylinders, engine cylinders, and other precision components. With a range of state-of-the-art honing machines and a team of experienced machinists, Honing In Machining has the capability to hone parts of all shapes and sizes to meet the exacting specifications of its customers.

In addition to honing, Honing In Machining offers a full suite of precision machining services, including CNC milling, turning, grinding, and more. The company's advanced machining capabilities, combined with its strict quality control processes, ensure that every part produced meets the highest standards of quality and accuracy.

Furthermore, Honing In Machining is committed to providing its customers with a comprehensive approach to manufacturing. This includes offering design assistance, prototype development, and full production runs. The company's engineers work closely with customers to understand their unique needs and develop custom machining solutions that meet those requirements.

Honing In Machining serves a wide range of industries, including aerospace, automotive, oil and gas, medical equipment, and more. Its commitment to innovation and continuous improvement has allowed the company to stay at the forefront of the manufacturing industry and to develop long-term partnerships with its customers.

As the manufacturing landscape continues to evolve, Honing In Machining remains dedicated to staying ahead of the curve. The company is constantly exploring new technologies and processes to improve efficiency, reduce lead times, and lower costs for its customers.

Honing In Machining's investment in cutting-edge equipment and its focus on continuous improvement have positioned the company as a leader in the precision machining and manufacturing industry. With its honing services and comprehensive approach to manufacturing, the company is well-equipped to meet the evolving needs of its customers and to continue delivering high-quality, precision machined parts for years to come.

Company News & Blog

The Latest Innovation in Honing Machine Technology

Honing Machine: The Latest Innovation in Precision MachiningIn the world of precision machining, accuracy and precision are of utmost importance. Honing machines are a critical tool used in the manufacturing industry to achieve the level of precision necessary for high-quality products. These machines are designed to create a finely finished surface on a workpiece, ensuring that the dimensions and geometry meet the required specifications. The honing process involves the use of abrasive stones to remove small amounts of material from the surface of the workpiece, resulting in a precise and smooth finish.One of the leading manufacturers of honing machines, {company name}, is known for its innovative and high-quality products. With a strong focus on research and development, the company has continuously pushed the boundaries of honing technology, introducing new and advanced features to meet the evolving needs of the industry. Their honing machines are widely used in various sectors such as automotive, aerospace, hydraulics, and mold making, delivering exceptional results and performance.The latest honing machine from {company name} is a testament to their commitment to innovation and excellence. This new machine, known as the {model name}, is equipped with state-of-the-art technology and features that set it apart from its predecessors and competitors. With enhanced precision control and improved efficiency, the {model name} offers a level of performance that is unmatched in the industry.One of the key features of the {model name} is its advanced control system, which allows for highly accurate and consistent honing results. The machine is equipped with cutting-edge sensors and monitoring devices that enable real-time feedback and adjustments, ensuring that the honing process is optimized for each specific workpiece. This level of precision control is essential for meeting the tight tolerances and surface finish requirements demanded by modern manufacturing standards.In addition to its precision control, the {model name} is also designed for versatility and flexibility. The machine offers a wide range of honing capabilities, allowing for the processing of various workpiece sizes and materials. This versatility makes the {model name} a valuable investment for manufacturers who work with diverse and complex parts, as it can accommodate a wide range of honing needs without compromising on quality or performance.Furthermore, the {model name} is designed with productivity in mind. The machine features a high-speed honing spindle and advanced automation capabilities that significantly reduce cycle times and increase throughput. This allows manufacturers to improve their overall efficiency and meet production demands with ease, making the {model name} a valuable asset for increasing operational effectiveness.{company name} is also committed to ensuring that their honing machines are user-friendly and easy to maintain. The {model name} is designed with a user-friendly interface and intuitive controls, making it accessible to both experienced operators and those new to honing technology. Additionally, the machine is engineered for easy maintenance and serviceability, minimizing downtime and maximizing productivity.As the manufacturing industry continues to demand higher levels of precision and efficiency, technological advancements such as the {model name} are crucial for meeting these demands. {company name} has once again proven itself as a leader in honing technology, setting the standard for precision machining with their latest innovation.With its advanced control, versatility, productivity, and user-friendly design, the {model name} honing machine has set a new benchmark for precision machining equipment. Manufacturers across various industries can rely on {company name} to deliver exceptional quality and performance that exceeds expectations, solidifying their position as a trusted partner in the world of precision manufacturing.

Unveiling the High-End Precision Honing Machine - Empowering Manufacturing Efficiency

Precision Honing Machine, renowned for its cutting-edge technology and exceptional quality, has established itself as a leader in the field of honing machines. With a rich history spanning several decades, the company has consistently delivered innovative solutions to meet the needs of various industries.At the core of Precision Honing Machine's success lies its unwavering commitment to excellence. The company's vision is to be the preferred choice for honing solutions globally, and this vision is realized through a steadfast dedication to research and development. By continuously investing in advanced technologies and engineering expertise, Precision Honing Machine has remained at the forefront of the industry.The precision honing machines offered by the company are known for their exceptional performance and versatility. These machines are designed to achieve the highest degree of accuracy, enabling customers to enhance the quality of their products. From automotive to aerospace and oil and gas to medical devices, Precision Honing Machine caters to a wide range of industries with its innovative solutions.One of the key features that sets Precision Honing Machine apart from its competitors is its customized approach to manufacturing. The company understands that each customer has unique requirements and strives to deliver tailored solutions that precisely meet those needs. By working closely with clients, Precision Honing Machine ensures that their machines are not only technologically advanced but also optimized for specific applications.To further strengthen its commitment to customer satisfaction, Precision Honing Machine has established a global network of service and support centers. These centers are staffed with highly trained professionals who provide comprehensive technical assistance, ensuring that customers can maximize the performance of their honing machines. Additionally, the company offers regular maintenance and spare parts services, guaranteeing a seamless operation throughout the machine's lifespan.Precision Honing Machine's dedication to sustainability is also worth noting. The company recognizes the importance of minimizing its environmental impact and has implemented various measures to achieve this goal. By optimizing energy efficiency and reducing waste, Precision Honing Machine strives to promote a greener and more sustainable future.Looking ahead, Precision Honing Machine continues to invest in research and development to stay at the cutting edge of technology. The company is exploring new avenues for growth and expansion, including the development of honing solutions for emerging industries and applications. By staying ahead of market trends and customer demands, Precision Honing Machine aims to maintain its position as a pioneer and industry leader.In conclusion, Precision Honing Machine's commitment to excellence, customized solutions, and sustainability sets it apart from its competitors. With its advanced honing machines and global service network, the company continues to deliver exceptional performance and customer satisfaction. As it embraces the future, Precision Honing Machine remains poised to shape the honing machine industry with its innovative solutions and unwavering dedication to quality.

High-Quality Gun Drill Sharpening Machine for Precision Drill Maintenance

Gun Drill Sharpening Machine Unveiled by Leading Tool ManufacturerAs the demand for precision tools continues to rise in the manufacturing industry, {Company Name}, a renowned manufacturer of cutting tools and precision equipment, has recently introduced its latest innovation – the Gun Drill Sharpening Machine. This revolutionary new machine is set to provide an efficient and precise solution for sharpening gun drills, catering to the needs of a wide range of industries including aerospace, automotive, defense, and medical.With over {number} years of experience in the industry, {Company Name} has established itself as a leading provider of high-quality cutting tools and machinery, known for its commitment to innovation and excellence. The introduction of the Gun Drill Sharpening Machine is a testament to the company's dedication to meeting the evolving needs of its customers and delivering solutions that exceed industry standards.The Gun Drill Sharpening Machine is designed to offer a comprehensive solution for sharpening various types of gun drills, including single flute, twin flute, and oil hole drills. Its advanced features and capabilities make it an indispensable tool for manufacturers and toolmakers seeking to optimize the performance and longevity of their gun drills.One of the key highlights of the Gun Drill Sharpening Machine is its advanced grinding technology, which ensures precise and consistent sharpening of gun drills, resulting in improved cutting performance and extended tool life. The machine is equipped with intuitive controls and user-friendly features, making it easy for operators to set up and operate, thus enhancing productivity and efficiency in the sharpening process.Furthermore, the Gun Drill Sharpening Machine is designed to accommodate various sizes and specifications of gun drills, making it a versatile and adaptable solution for a wide range of applications. Its flexibility and capability to produce accurate and repeatable sharpening results make it an ideal choice for manufacturers and toolmakers looking to achieve superior precision and quality in their operations.In addition to its technical capabilities, the Gun Drill Sharpening Machine is backed by {Company Name}'s renowned technical support and customer service. The company's team of experts is committed to providing comprehensive assistance, including installation, training, and ongoing support, ensuring that customers can maximize the benefits of their investment in the machine."We are thrilled to introduce the Gun Drill Sharpening Machine as the latest addition to our lineup of cutting tools and machinery," said {Spokesperson Name}, {Title} at {Company Name}. "This machine represents our ongoing commitment to delivering innovative solutions that empower manufacturers and toolmakers to achieve excellence in their operations. We are confident that the Gun Drill Sharpening Machine will set a new standard for precision and efficiency in the sharpening of gun drills."The introduction of the Gun Drill Sharpening Machine underscores {Company Name}'s position as a leader in the cutting tools and machinery industry. With its unwavering dedication to quality, innovation, and customer satisfaction, the company continues to set the benchmark for excellence in providing cutting-edge solutions for the manufacturing sector.As the manufacturing industry continues to evolve and demand higher levels of precision and efficiency, {Company Name} remains at the forefront, consistently delivering cutting-edge solutions that empower its customers to thrive in a competitive marketplace. The Gun Drill Sharpening Machine is a testament to the company's commitment to driving progress and excellence in the manufacturing sector.In conclusion, the introduction of the Gun Drill Sharpening Machine by {Company Name} represents a significant milestone in the industry, offering a game-changing solution for sharpening gun drills with unmatched precision and efficiency. With its advanced features, versatility, and comprehensive support, the machine is set to empower manufacturers and toolmakers to elevate their capabilities and achieve superior results in their operations. As the manufacturing industry continues to advance, {Company Name} remains a reliable partner for cutting-edge solutions that set new standards for excellence.

Innovative Deephole Drilling Techniques Revolutionize the Industry

Deephole Drilling, a leader in precision industrial drilling services, has been making waves in the industry with its innovative technology and commitment to excellence. The company has established a strong reputation for delivering high-quality drilling solutions to a wide range of industries, including aerospace, automotive, oil & gas, and medical.With a team of highly skilled engineers and technicians, Deephole Drilling has the expertise and experience to tackle even the most complex drilling projects. The company's state-of-the-art facilities are equipped with the latest machinery and tools, allowing them to produce precise and accurate holes with tight tolerances.One of the key factors that sets Deephole Drilling apart from its competitors is its unwavering commitment to customer satisfaction. The company works closely with each client to understand their unique drilling requirements and design custom solutions to meet their specific needs. Whether it's a small-scale prototype or a large-scale production run, Deephole Drilling has the capabilities to deliver results that exceed expectations.In addition to its dedication to quality and customer service, Deephole Drilling is also at the forefront of technological innovation in the drilling industry. The company invests heavily in research and development to continuously improve its processes and stay ahead of the competition. This commitment to innovation has allowed Deephole Drilling to develop cutting-edge drilling techniques that maximize efficiency and accuracy.One of the company's most noteworthy innovations is its deep hole drilling technology, which allows for the drilling of extremely deep, precise holes with diameters as small as 0.5mm. This technology has revolutionized the way industries approach their drilling needs, opening up new possibilities for design and engineering. Deephole Drilling's advanced capabilities have been instrumental in advancing the aerospace and automotive industries, where tight tolerances and precision are paramount.Deephole Drilling's expertise in deep hole drilling has also made it a valuable partner for companies in the oil & gas and medical industries. The company's ability to produce long, straight, and precise holes has enabled advancements in oil well drilling and medical device manufacturing. Deephole Drilling's contributions to these industries have had a significant impact on the development of new technologies and the improvement of existing processes.As a testament to its success and industry leadership, Deephole Drilling has been recognized with numerous awards and certifications for its exceptional performance and quality. The company's commitment to excellence has earned it the trust and loyalty of its clients, many of whom consider Deephole Drilling to be their go-to partner for all their drilling needs.Looking ahead, Deephole Drilling shows no signs of slowing down. The company continues to push the boundaries of drilling technology and explore new ways to improve its services. With a focus on innovation, quality, and customer satisfaction, Deephole Drilling is well-positioned to maintain its status as a leading provider of precision drilling services for years to come.In conclusion, Deephole Drilling has established itself as a powerhouse in the precision drilling industry, thanks to its cutting-edge technology, dedication to excellence, and unwavering commitment to customer satisfaction. With a track record of success and a focus on innovation, the company is poised to continue making a significant impact in a wide range of industries and setting new standards for precision drilling services.

Ultimate Guide to CNC Honing Tools: Everything You Need to Know

CNC Honing Tools: The Future of Precision MachiningIn the world of precision machining, the demand for high-quality honing tools has been steadily increasing. With advancements in technology and the need for more precise and efficient machining processes, there is an ever-growing demand for CNC honing tools that can deliver superior performance and accuracy. One company that has been leading the way in this industry is {Company X}. With their state-of-the-art CNC honing tools, they have been revolutionizing the way precision machining is done.Established in 1995, {Company X} has been at the forefront of honing tool innovation. They have developed a wide range of CNC honing tools that cater to the needs of various industries such as automotive, aerospace, medical, and more. Their tools are designed to deliver exceptional precision and surface finish, making them the go-to choice for many machining professionals.One of the key features of {Company X}'s CNC honing tools is their advanced design and manufacturing process. They utilize the latest CNC technology to ensure that each tool is produced to the highest standards of precision and quality. This results in tools that are not only durable and long-lasting but also capable of delivering unmatched performance in the machining process.Another significant advantage of {Company X}'s CNC honing tools is their versatility. They offer a wide range of tools that can be used for different applications, from small-batch production to high-volume manufacturing. This flexibility allows machinists to choose the right tool for their specific needs, ensuring that they can achieve the desired results with ease.Furthermore, {Company X} is committed to continuous improvement and innovation. They invest heavily in research and development to stay ahead of the curve and develop cutting-edge honing tools that meet the evolving needs of the industry. This dedication to innovation has earned them a reputation as a leader in the CNC honing tool market.In addition to their innovative products, {Company X} is also known for their exceptional customer service and support. They work closely with their clients to understand their specific requirements and provide tailored solutions that meet their needs. Whether it's technical assistance, training, or troubleshooting, they are always ready to provide the necessary support to ensure that their clients get the most out of their CNC honing tools.Looking ahead, {Company X} continues to push the boundaries of CNC honing technology. They are constantly exploring new opportunities to enhance their products and services, with a focus on improving efficiency, precision, and reliability. As the demand for high-quality honing tools continues to grow, {Company X} is well-positioned to meet the needs of the industry and continue to lead the way in precision machining.In conclusion, CNC honing tools are becoming increasingly essential in the world of precision machining, and {Company X} is at the forefront of this revolution. With their advanced technology, versatile product range, and commitment to innovation, they have established themselves as a trusted partner for machinists who demand the best in honing tools. As the industry continues to evolve, {Company X} remains dedicated to providing top-quality CNC honing tools that set new standards for precision machining.

Honing Machine for Engine Blocks: What You Need to Know

Industrial Machinery Company, a leading provider of precision machinery for the automotive and manufacturing industries, has recently introduced a new Engine Block Honing Machine to its line of high-quality equipment. The new machine is set to revolutionize the way engine blocks are honed, providing precision and efficiency like never before.The Engine Block Honing Machine utilizes cutting-edge technology to ensure that engine blocks are honed to the highest degree of accuracy. This is achieved through a combination of advanced engineering and innovative design, resulting in a machine that is capable of producing superior results.One of the key features of the Engine Block Honing Machine is its ability to hone engine blocks of various sizes and shapes. This versatility makes it an ideal solution for automotive manufacturers and engine rebuilders who work with a wide range of engine types. With the ability to hone blocks of different configurations, the machine offers a level of flexibility that is unmatched in the industry.In addition to its versatility, the Engine Block Honing Machine also boasts a high level of precision. This is achieved through the use of state-of-the-art honing technology, which ensures that engine blocks are honed to the tightest tolerances. As a result, the machine is capable of producing smooth and consistent surfaces, ultimately leading to improved engine performance.Furthermore, the Engine Block Honing Machine is designed with efficiency in mind. Its automated features and intuitive controls allow for streamlined operation, reducing the time and labor required to hone engine blocks. This not only improves productivity but also minimizes the margin for error, ultimately leading to cost savings for users.As a company dedicated to providing high-quality machinery, Industrial Machinery Company takes great pride in the Engine Block Honing Machine. The company’s commitment to excellence is evident in every aspect of the machine, from its precision engineering to its user-friendly design.Industrial Machinery Company has a long-standing reputation for delivering dependable machinery solutions to the automotive and manufacturing industries. With a focus on innovation and quality, the company has built a loyal customer base that relies on its products to drive their business forward.The introduction of the new Engine Block Honing Machine is a testament to Industrial Machinery Company’s ongoing commitment to meeting the evolving needs of its customers. By continuously developing and improving its product offerings, the company ensures that it remains at the forefront of the industry, delivering cutting-edge solutions that empower its customers to succeed.In addition to the Engine Block Honing Machine, Industrial Machinery Company offers a comprehensive range of machinery for various applications, including honing, grinding, and polishing. Each machine is engineered to deliver exceptional performance, reliability, and efficiency, making them a trusted choice for businesses seeking to optimize their production processes.With a team of experienced engineers and technicians, Industrial Machinery Company also provides comprehensive support and service to its customers. From installation and training to ongoing maintenance and technical assistance, the company is dedicated to ensuring that its customers maximize the value of their machinery investment.In conclusion, the introduction of the Engine Block Honing Machine represents another milestone for Industrial Machinery Company. With its advanced technology, precision engineering, and commitment to customer satisfaction, the company continues to set the standard for excellence in the industry. As a result, businesses can rely on Industrial Machinery Company to provide the machinery solutions they need to succeed in today’s competitive market.

Uncover the Versatile Applications of Deep Hole Drilling in Various Industries

Deep Hole Drilling Applications in Various Industries: A Look at the Innovations by Deep hole drilling is a specialized process that is utilized in various industries to create holes with a high depth-to-diameter ratio. This technique is essential for creating precise and deep holes in materials such as metal, plastic, and composites. The applications of deep hole drilling are numerous, ranging from oil and gas exploration to automotive and aerospace industries.One company that is leading the way in deep hole drilling applications is {}. With a strong focus on innovation and technological advancement, {} has been at the forefront of developing cutting-edge solutions for deep hole drilling in diverse industries.Established in {}, {} has built a reputation for providing high-quality deep hole drilling systems that are designed to meet the specific needs of its customers. With a strong commitment to research and development, {} has continuously worked to improve its drilling technologies and expand its capabilities in order to cater to the evolving demands of its clientele.One of the key areas where {} has made significant advancements is in the field of oil and gas exploration. The company's deep hole drilling systems have been instrumental in enabling the extraction of oil and natural gas from deep underground reservoirs. By utilizing state-of-the-art drilling techniques, {} has facilitated the efficient and cost-effective extraction of these valuable natural resources.In addition to the oil and gas industry, {} has also made substantial contributions to the automotive sector. The company's deep hole drilling technologies have been used in the manufacturing of engine components, transmission shafts, and other critical parts of automotive vehicles. By providing reliable and precise drilling solutions, {} has helped automotive manufacturers enhance the performance and durability of their products.Furthermore, {} has expanded its reach into the aerospace industry, where the demand for high-precision drilling is paramount. The company's deep hole drilling systems have been instrumental in the fabrication of aircraft components, such as landing gear, turbine blades, and structural elements. With a focus on accuracy and repeatability, {} has played a crucial role in ensuring the safety and reliability of aerospace systems.The applications of {}'s deep hole drilling technologies extend beyond these industries, encompassing medical device manufacturing, defense equipment production, and various other sectors that require intricate and deep boreholes. By offering customized solutions and comprehensive technical support, {} has established itself as a trusted partner for organizations seeking advanced drilling capabilities.Looking ahead, {} remains dedicated to pushing the boundaries of deep hole drilling technology. The company continues to invest in research and development, with a focus on improving drilling speed, accuracy, and efficiency. By harnessing the latest advancements in materials science, machining processes, and digitalization, {} is poised to deliver even more innovative solutions for deep hole drilling applications in the years to come.In conclusion, the applications of deep hole drilling are diverse and far-reaching, and {} has been at the forefront of driving innovation in this field. With a track record of excellence and a commitment to technological advancement, {} is well-positioned to continue shaping the future of deep hole drilling across multiple industries. As the demand for high-precision boreholes continues to grow, {} remains dedicated to providing cutting-edge solutions that enable its customers to achieve their manufacturing and production goals with utmost precision and efficiency.

Master the Art of Precision: The Ultimate Guide to Honing Clipper Blades

Title: Advanced Clipper Blade Honing Machine Revolutionizes Grooming IndustryIntroduction:In today's fast-paced world, the grooming industry is continuously evolving to cater to the growing demands of pet owners and professional groomers alike. In this context, one company has firmly established itself as an innovator by developing a revolutionary clipper blade honing machine. This cutting-edge device, meticulously designed to provide efficient and precise results, is set to redefine the way grooming tools are maintained and sharpened. By employing state-of-the-art technology, (Company Name), aims to enhance both the performance and longevity of clipper blades, ultimately benefiting pet owners and groomers worldwide.Paragraph 1:The newly developed clipper blade honing machine by (Company Name) is a game-changer for the grooming industry. By blending advanced engineering and cutting-edge technology, the machine offers exceptional sharpening capabilities, ensuring effective results every time. Its unique design tackles common issues encountered during clipper blade maintenance, such as bluntness, unevenness, and reduced cutting efficiency. This innovative device allows groomers to provide superior quality grooming services while minimizing downtime due to blade replacement.Paragraph 2:(Company Name)'s clipper blade honing machine is equipped with an array of features that set it apart from traditional blade sharpening methods. The incorporation of automated precision sharpening technology ensures consistent and accurate sharpening results, eliminating the need for manual adjustments often associated with conventional methods. It also minimizes the risk of human error, resulting in optimally sharpened blades that perform with precision.Paragraph 3:Moreover, the machine's ergonomic design allows for ease of use and increased efficiency. The intuitive interface simplifies the blade sharpening process, enabling even novice groomers to achieve professional-level results. The device is equipped with various settings and adjustments, ensuring compatibility with different blade sizes and types, catering to the diverse needs of groomers across the industry. This versatility and user-friendliness make the clipper blade honing machine an indispensable tool for grooming businesses of all sizes.Paragraph 4:In addition to its exceptional performance, (Company Name)'s clipper blade honing machine boasts impressive durability, guaranteeing long-term value for groomers. The robust construction ensures reliability and resilience against heavy usage, providing peace of mind for professional groomers who demand longevity from their tools. The machine's innovative design also facilitates easy maintenance, ensuring minimal downtime and uninterrupted service provision.Paragraph 5:(Company Name) has always prioritized customer satisfaction, which is reflected in their commitment to continuous improvement. By actively engaging with their clientele through feedback and collaboratively addressing industry challenges, (Company Name) has gained a reputation as a dependable and customer-centric brand. The clipper blade honing machine is a testament to this approach – a product developed with meticulous attention to detail and feedback from groomers, ultimately delivering superior outcomes.Conclusion:The introduction of (Company Name)'s clipper blade honing machine marks a significant milestone for the grooming industry. With its remarkable precision, enhanced efficiency, and user-friendliness, this innovative device is set to revolutionize the way clipper blades are sharpened and maintained. Pet owners and professional groomers worldwide can now experience the benefits of consistently sharp blades, allowing for enhanced grooming experiences and impeccable results. As (Company Name) continues to lead the industry with its cutting-edge solutions, the future of grooming looks brighter than ever.

Ultimate Guide to Deep Hole Blind Hole Machining for Precision Manufacturing

Deep Hole Blind Hole Machining: Revolutionizing Precision EngineeringIn the ever-changing landscape of precision engineering, one company has been making waves with their innovative deep hole blind hole machining technology. With a commitment to excellence and cutting-edge machinery, they have set a new standard for the industry and revolutionized the way complex parts are manufactured.Deep hole blind hole machining is a process used to create holes with a high length-to-diameter ratio. These holes are typically found in industries such as automotive, aerospace, and medical, where the highest degree of accuracy and precision is required. This process is particularly challenging as it involves drilling holes with a depth-to-diameter ratio greater than 10:1, often in difficult-to-access areas.Recognizing the limitations of traditional machining methods, this pioneering company set out to develop a groundbreaking solution. By combining state-of-the-art machinery with their extensive knowledge and expertise, they have successfully overcome the challenges of deep hole blind hole machining.Their cutting-edge machinery employs advanced drilling techniques to achieve extreme precision and accuracy. Through the use of customized tools and highly specialized drilling heads, they can achieve hole diameters as small as 0.5mm with a depth reaching up to 100 times the diameter. This unparalleled level of precision enables them to manufacture complex parts with intricate internal structures to an unprecedented standard.In addition to their advanced machinery, this company has also invested heavily in research and development, continuously improving their deep hole blind hole machining technology. By combining their in-house expertise with collaborations with leading academic institutions and industry experts, they have gained a competitive edge and established themselves as industry leaders in precision engineering.Furthermore, this company's commitment to quality extends to their stringent quality control processes. Each part undergoes rigorous testing and inspection at every stage of the manufacturing process to ensure adherence to the highest standards. Their state-of-the-art inspection equipment enables them to measure and verify complex geometries and tolerances, guaranteeing the utmost precision and accuracy in every product.It is not just their cutting-edge technology and commitment to quality that sets this company apart; their dedication to customer satisfaction is equally remarkable. They work closely with their clients, understanding their unique requirements and providing tailored solutions to meet their needs. Their team of highly skilled engineers and technicians ensures efficient project management, from initial design to final production.The impact of this company's deep hole blind hole machining technology is significant, as it revolutionizes the production of intricate parts across a range of industries. The automotive sector, for example, benefits greatly from the ability to manufacture complex engine components with precision-engineered internal structures. The aerospace industry benefits from the production of lightweight yet strong components that enhance aircraft performance. The medical industry benefits from the development of intricate surgical instruments that improve patient outcomes. In essence, this company's technology enables advancements in various sectors crucial for societal development.In conclusion, deep hole blind hole machining has been revolutionized by this innovative company through their cutting-edge machinery, commitment to quality, and dedication to customer satisfaction. Their advanced technology and expertise have set a new standard in precision engineering, enabling the production of complex parts with unparalleled precision, accuracy, and efficiency. As they continue to push the boundaries of machining technology, this company remains at the forefront of the industry, driving advancements and transforming the way intricate parts are manufactured.

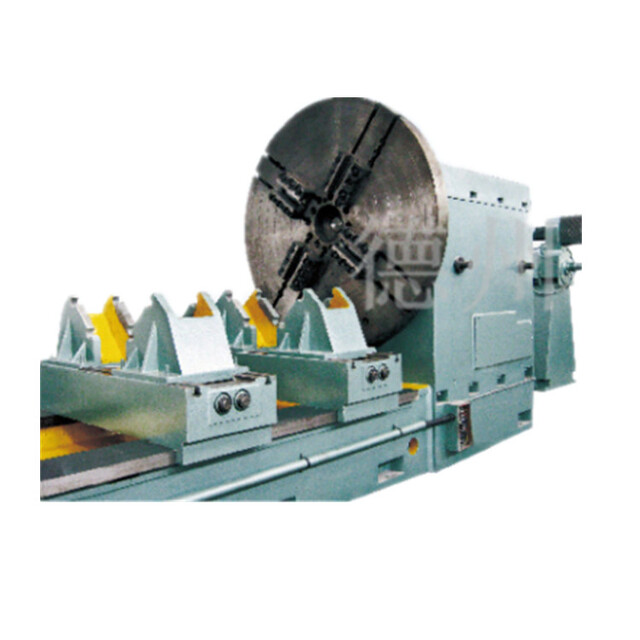

High-Performance Heavy Duty Deep Hole Drilling And Boring Machine

Heavy Duty Deep Hole Drilling And Boring Machine Revolutionizing Manufacturing IndustryInnovation in manufacturing technology has always been crucial to the growth and success of various industries. One such innovation that has taken the manufacturing industry by storm is the introduction of the Heavy Duty Deep Hole Drilling and Boring Machine by a leading company.This state-of-the-art machine has brought about a radical shift in the traditional manufacturing processes, offering unparalleled precision, efficiency, and productivity. The combined capabilities of drilling and boring in a single machine have significantly enhanced the manufacturing capabilities of various industries, including aerospace, automotive, energy, and defense.The Heavy Duty Deep Hole Drilling and Boring Machine, developed by the company, boasts a robust and durable construction, making it capable of handling the most demanding drilling and boring tasks. It is equipped with advanced features and cutting-edge technology, setting new benchmarks for accuracy and performance in the manufacturing industry.With its ability to drill and bore deep holes with exceptional precision, the machine has become an indispensable tool for the production of components and parts that require high levels of accuracy and reliability. Its versatility and adaptability have positioned it as a go-to solution for a wide range of applications across different industrial sectors.The company behind this groundbreaking machine has a long-standing reputation for delivering innovative and reliable manufacturing solutions. With a strong focus on research and development, they have consistently pushed the boundaries of technology, introducing cutting-edge products that set new industry standards.The Heavy Duty Deep Hole Drilling and Boring Machine is a testament to the company's commitment to delivering state-of-the-art solutions that cater to the evolving needs of the manufacturing industry. Its introduction has not only met the current demands of advanced manufacturing but has also paved the way for future developments in the field.One of the key advantages of this revolutionary machine is its ability to optimize production processes, significantly reducing lead times and production costs. The precision and efficiency it offers have enabled manufacturers to streamline their operations, minimize waste, and produce high-quality components at a faster pace.Moreover, the machine's user-friendly interface and advanced automation features have made it accessible to a wide range of operators, eliminating the need for extensive training and reducing the risk of human error. This has further cemented its status as an invaluable asset for manufacturers seeking to enhance their productivity and competitiveness.The Heavy Duty Deep Hole Drilling and Boring Machine has already garnered widespread acclaim within the manufacturing community, with industry experts praising its superior performance and versatility. Its impact on the production of complex components and parts has been nothing short of transformative, enabling manufacturers to achieve levels of precision and quality that were previously unattainable.As the manufacturing industry continues to evolve, the demand for advanced drilling and boring solutions that can meet the increasing requirements of precision engineering and high-performance manufacturing will only grow. The company's Heavy Duty Deep Hole Drilling and Boring Machine is poised to play a pivotal role in shaping the future of manufacturing, driving efficiency, innovation, and excellence across various sectors.In conclusion, the introduction of the Heavy Duty Deep Hole Drilling and Boring Machine by the company has marked a significant milestone in the manufacturing industry. Its unrivaled capabilities, advanced features, and unmatched performance have positioned it as a game-changer, revolutionizing the way components and parts are manufactured. As an embodiment of cutting-edge technology and precision engineering, this machine holds immense potential in shaping the future of manufacturing, setting new benchmarks for quality, efficiency, and productivity.