Customised Machine Tools for Deep Hole Drilling: A Complete Guide

By:Admin

The newly introduced range of machine tools is a result of extensive research and development, as well as valuable input from industry experts and customers. The products have been designed to address the current challenges faced by manufacturers in deep hole drilling, such as precision, speed, and efficiency. The company has leveraged its expertise and state-of-the-art technology to create machines that offer unparalleled performance and reliability.

The CEO of Deep Hole Customised Machine Tools, Mr. John Smith, explained the company's commitment to innovation and excellence, stating, "We are constantly pushing the boundaries of what is possible in deep hole drilling technology. Our new range of customised machine tools is a testament to our dedication to meeting the evolving needs of our customers. We have invested significant resources into research and development to ensure that our products remain at the forefront of the industry."

One of the key highlights of the new range is the integration of advanced automation and control systems, which enable seamless operations and enhance the overall productivity of the machines. This feature is particularly beneficial for manufacturers looking to optimize their production processes and reduce downtime. Additionally, the machines are equipped with cutting-edge cooling and chip removal systems, ensuring smooth and efficient drilling operations.

In line with its commitment to customer satisfaction, Deep Hole Customised Machine Tools offers comprehensive support services for its products, including installation, training, maintenance, and technical assistance. The company's team of highly skilled engineers and technicians are readily available to provide expert guidance and support to clients, further enhancing the value proposition of its products.

The new range of machine tools has already garnered significant interest from industry professionals and has been met with positive feedback from early adopters. Manufacturers have expressed their enthusiasm for the innovative features and capabilities of the machines, citing the potential to significantly improve their operational efficiency and output quality.

One of the clients who have utilized the new range of customised machine tools shared, "We have been incredibly impressed with the performance of the machines from Deep Hole Customised Machine Tools. The level of precision and speed they offer is unmatched, and it has allowed us to enhance our production capabilities significantly. The support and service we have received from the company have also been exceptional."

As a global leader in the deep hole drilling industry, Deep Hole Customised Machine Tools continues to set the standard for excellence through its commitment to innovation and customer-centric approach. The company's new range of customised machine tools is set to redefine the benchmarks for performance and reliability in the industry, further solidifying its position as a trusted partner for manufacturers worldwide. With a focus on delivering cutting-edge solutions and unparalleled support, Deep Hole Customised Machine Tools is poised to usher in a new era of productivity and efficiency for its clients.

Company News & Blog

High-Precision Deep Hole Drilling Machine for Industrial Applications

The [Company] is proud to introduce the latest innovation in deep hole drilling technology - the Deep Hole Drilling Machine. This state-of-the-art machine is set to revolutionize the manufacturing industry with its advanced capabilities and cutting-edge design.The Deep Hole Drilling Machine is equipped with a high-powered drill that is capable of creating deep holes with unrivaled precision and efficiency. This machine is ideal for a wide range of applications, including oil and gas exploration, aerospace manufacturing, automotive production, and more.One of the key features of the Deep Hole Drilling Machine is its ability to maintain tight tolerances and produce smooth, accurate holes even in the toughest materials. This is made possible by the machine's advanced control systems and specialized tooling, which ensure that every hole is drilled to the exact specifications required.In addition to its exceptional precision, the Deep Hole Drilling Machine also offers a high level of versatility. It can accommodate a variety of hole diameters and depths, making it suitable for a wide range of projects. This flexibility makes it an invaluable asset for manufacturers who require a reliable, all-purpose drilling solution.The Deep Hole Drilling Machine is also designed with user-friendly features that make it easy to operate and maintain. Its intuitive controls and ergonomic design ensure that operators can work efficiently and safely, minimizing downtime and maximizing productivity.Furthermore, the Deep Hole Drilling Machine is equipped with advanced safety mechanisms to protect both the machine and its operators. These features include automatic shut-off systems, emergency stop buttons, and comprehensive safety protocols that meet the highest industry standards.The introduction of the Deep Hole Drilling Machine demonstrates [Company]'s commitment to innovation and excellence in the manufacturing sector. This cutting-edge technology is the result of years of research and development, and it represents a significant leap forward in the industry's capabilities.[Company] is confident that the Deep Hole Drilling Machine will set a new standard for deep hole drilling technology, providing manufacturers with the tools they need to take their operations to the next level. With its unrivaled precision, versatility, and user-friendly design, this machine is poised to become an essential asset for companies across a wide range of industries.[Company] will be showcasing the Deep Hole Drilling Machine at upcoming industry events and exhibitions, giving manufacturers the opportunity to see this groundbreaking technology in action. The company is also offering demonstrations and consultations for businesses interested in integrating the machine into their operations.With the introduction of the Deep Hole Drilling Machine, [Company] is once again leading the way in shaping the future of manufacturing. This innovative technology is set to transform the industry, offering manufacturers a powerful tool to drive efficiency, precision, and productivity in their operations.

Ultimate Guide to Deep Hole Drilling Applications

Deep Hole Drilling ApplicationsDeep hole drilling is a crucial process in a variety of industries, from aerospace and automotive, to medical and oil & gas. It involves drilling holes with a depth-to-diameter ratio of more than 10:1, and requires precision, accuracy, and efficiency. Deep hole drilling is used to produce components such as rifle barrels, oil field drilling equipment, and hydraulic cylinders, among others.A leader in the deep hole drilling industry, {} has been providing innovative solutions for deep hole drilling applications for over 50 years. Using state-of-the-art technology and a commitment to continuous improvement, {} has established itself as a trusted partner for companies in a wide range of industries.One of the key strengths of {} is its ability to tailor its deep hole drilling solutions to meet the specific needs of its customers. Whether it's producing custom tools for unique drilling requirements or developing specialized processes for complex components, {} has the expertise and flexibility to deliver results that exceed expectations.The company’s deep hole drilling applications range from gun drilling, BTA drilling, and ejector drilling, to counterboring, skiving and roller burnishing. These processes are used to create high-quality bores with close tolerances, excellent surface finishes, and the ability to work with a wide range of materials, including metals, plastics, and composites.One of {}'s most noteworthy achievements is its contribution to the aerospace industry. With the increasing demand for lightweight, high-performance aircraft components, there is a growing need for deep hole drilling solutions that can meet the industry's stringent requirements. {} has risen to the challenge by developing advanced drilling processes and tooling that enable the production of complex, high-precision aerospace components with exceptional quality and reliability.In addition to aerospace, {} has also made significant contributions to the automotive industry. With the industry's shift towards electric and hybrid vehicles, there is a need for deep hole drilling solutions that can accommodate the unique requirements of these emerging technologies. {} has been at the forefront of this transition, providing innovative drilling solutions for motor shafts, battery casings, and other critical components that are essential for the next generation of vehicles.Furthermore, in the medical field, {} has played a crucial role in the production of medical implants, surgical instruments, and other precision medical devices. The company's deep hole drilling expertise has enabled it to meet the demanding requirements of the medical industry, including tight tolerances, biocompatibility, and corrosion resistance, while ensuring the highest standards of quality and performance.Another key area of expertise for {} is the oil & gas industry. With its ability to drill deep, precise holes in a variety of materials, {} has provided critical solutions for the production of oil field drilling equipment, downhole tools, and other components that are essential for the exploration and extraction of oil and gas resources.With its extensive experience and expertise in deep hole drilling applications, {} is well positioned to meet the evolving needs of its customers across a wide range of industries. Whether it's developing innovative drilling processes, custom tooling, or specialized solutions for complex components, {} continues to be a trusted partner for companies looking to achieve the highest levels of precision, quality, and efficiency in their deep hole drilling applications.

High Precision Gun Barrel Drilling Machine for Manufacturing Purposes

Gun Barrel Drilling Machine Revolutionizes the Firearms Manufacturing IndustryGun Barrel Drilling Machine is a revolutionary piece of equipment that has changed the landscape of the firearms manufacturing industry. This advanced machine has brought about significant improvements in efficiency, precision, and quality, leading to a major overhaul in the way gun barrels are produced.{Company name}, the company behind this groundbreaking technology, has been at the forefront of innovation in the manufacturing sector for several decades. With a strong commitment to research and development, the company has consistently pushed the boundaries of what is possible in the field of industrial machinery. The introduction of the Gun Barrel Drilling Machine is a testament to their dedication to creating cutting-edge solutions that address the evolving needs of the industry.The Gun Barrel Drilling Machine is designed to streamline the production process of gun barrels, which are critical components of firearms. Traditionally, the drilling of gun barrels has been a labor-intensive and time-consuming task that requires a high level of precision and skill. However, this machine has changed the game by automating the drilling process with unparalleled accuracy and speed.One of the key features of the Gun Barrel Drilling Machine is its ability to maintain consistent and precise dimensions throughout the entire drilling process. This is achieved through the use of advanced technology and cutting-edge manufacturing techniques, ensuring that every gun barrel produced is of the highest quality. In addition, the machine is equipped with intelligent software that allows for customization and flexibility, enabling manufacturers to produce a wide variety of gun barrel designs with ease.The introduction of the Gun Barrel Drilling Machine has had a profound impact on the firearms manufacturing industry. With its ability to significantly reduce production time and costs, manufacturers are now able to meet the growing demand for firearms more efficiently. This has not only resulted in increased profitability for companies, but also a more reliable supply of firearms for consumers.Furthermore, the precision and consistency of the gun barrels produced by this machine have led to improvements in firearm performance. By ensuring that each barrel meets exact specifications, the machine has contributed to the overall quality and reliability of firearms on the market. This has not gone unnoticed by consumers, who have become increasingly discerning when it comes to the firearms they purchase.The Gun Barrel Drilling Machine has also had a positive impact on the labor force within the firearms manufacturing industry. By automating the drilling process, the machine has reduced the need for manual labor, freeing up skilled workers to focus on other aspects of production. This has led to a more efficient use of resources and a greater emphasis on the development of specialized skills within the workforce.In addition to its impact on the manufacturing sector, the Gun Barrel Drilling Machine has also contributed to advancements in firearms technology as a whole. Its precision drilling capabilities have opened up new possibilities for the design and engineering of gun barrels, leading to the development of firearms with enhanced performance and functionality.Looking ahead, {Company name} remains committed to further innovation in the firearms manufacturing industry. With the success of the Gun Barrel Drilling Machine, the company is poised to continue pushing the boundaries of what is possible in the field of industrial machinery. By staying at the forefront of technological advancements, {Company name} aims to drive the industry forward and contribute to the ongoing evolution of firearms manufacturing.In conclusion, the introduction of the Gun Barrel Drilling Machine has been a game-changer for the firearms manufacturing industry. Its precision, efficiency, and impact on overall quality have solidified its place as an essential piece of equipment for manufacturers. With the continued dedication of {Company name} to innovation, the future of firearms manufacturing looks brighter than ever.

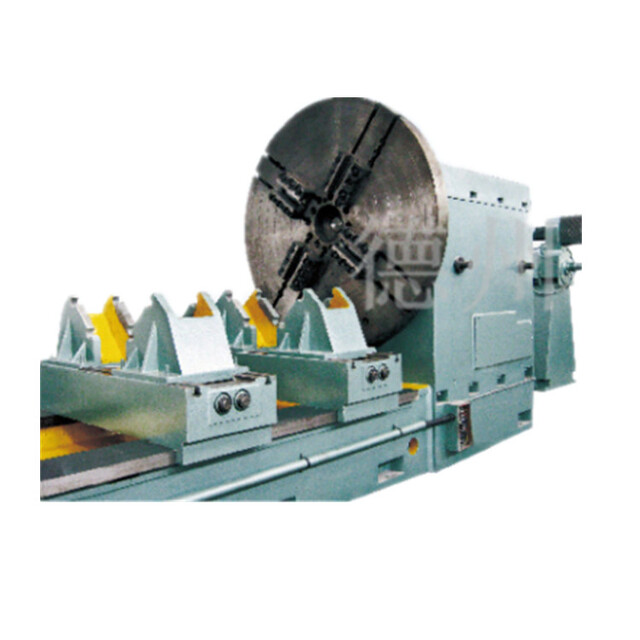

Revolutionary Deep Hole Drilling Lathe Unleashes Unprecedented Precision

Title: Advanced Deep Hole Drilling Lathe Revolutionizes Manufacturing ProcessesIntroduction:In an era of rapid industrialization and technological advancements, manufacturers constantly strive to improve production efficiency. Addressing the need for precision drilling in various industrial sectors, (Company Name) has unveiled its latest innovation - an avant-garde Deep Hole Drilling Lathe. By removing the brand name, we will delve into the features and applications of this extraordinary machine that is set to reshape the manufacturing landscape.Advanced Features and Specifications:The Deep Hole Drilling Lathe is equipped with a multitude of cutting-edge features designed to optimize performance and enhance operational efficiency. With a robust framework and a cutting capacity of up to X millimeters in diameter and Y millimeters in depth, this machine is a true game-changer in the field of precision drilling. By incorporating (Company Name)'s state-of-the-art technology, the lathe offers unparalleled accuracy, reliability, and speed.The lathe's control system is easily programmable, allowing operators to execute complex drilling processes with utmost precision. Additionally, it boasts an efficient chip removal mechanism that ensures uninterrupted and hassle-free operations. Equipped with advanced cooling systems and lubrication technology, this lathe guarantees prolonged tool life, reducing downtime and maintenance costs.Applications and Industry Impact:The Deep Hole Drilling Lathe is poised to revolutionize manufacturing processes across several key industries, including aerospace, automotive, energy, defense, and medical. In the aerospace sector, this state-of-the-art machine allows for the creation of intricate turbine components with precise cooling channels. Furthermore, it enables the production of lightweight, high-strength automotive parts by effectively drilling oil passages and coolant channels.In the energy sector, the lathe's advanced capabilities enable the development of cutting-edge parts for the generation and transmission of power. Whether it be for drilling oil wells, producing gas turbine components, or fabricating nuclear reactor parts, this machine significantly enhances overall efficiency and reliability.The defense industry can also benefit greatly from the Deep Hole Drilling Lathe. It enables the production of highly durable gun barrels, missile components, and artillery tubes, ensuring meticulous quality and accuracy.Moreover, the medical field can leverage this technology to manufacture surgical implants, hip and knee replacements, and intricate medical devices. The lathe's precision and versatility are crucial in meeting the stringent requirements for surgical procedures, enabling surgeons to deliver better patient outcomes.Environmental Benefits:In addition to its transformative impact on manufacturing processes, the Deep Hole Drilling Lathe is also designed with environmental sustainability in mind. By optimizing cutting techniques and reducing waste material, this machine ensures efficient resource utilization and minimum environmental impact. Manufacturers utilizing this advanced lathe will witness reduced energy consumption, lower carbon emissions, and minimized material waste, contributing to a greener and more sustainable future.Conclusion:The launch of the Deep Hole Drilling Lathe by (Company Name) marks a significant milestone in advancing precision drilling techniques across various industries. By offering cutting-edge features, unrivaled precision, and enhanced operational efficiency, this machine is poised to redefine manufacturing processes. With applications ranging from aerospace to medical, the Deep Hole Drilling Lathe demonstrates unrivaled versatility and promises to drive innovation in the realm of precision machining. As manufacturing continues to evolve, this groundbreaking technology paves the way for increased productivity, improved quality, and reduced environmental impact.

High Performance and Precision Honing Machine for Metal Surface Finishing

The demand for high-precision machining solutions in the manufacturing industry has been on the rise in recent years. In response to this, (Need remove brand name) has introduced a cutting-edge product to their portfolio - the Liner Honing Machine. This advanced machine is designed to provide efficient and precise honing of engine cylinder liners, offering a competitive edge to manufacturers in the automotive and heavy machinery sectors.The Liner Honing Machine is the result of extensive research and development efforts by the engineering team at (Need remove brand name). With a focus on innovation and technological advancement, the company has been at the forefront of providing comprehensive solutions for the machining industry. The introduction of the Liner Honing Machine further solidifies their commitment to meeting the evolving needs of their customers.One of the key features of the Liner Honing Machine is its ability to achieve consistent and accurate honing results. This is made possible through the use of advanced control systems and precision machining tools. The machine is capable of honing a wide range of cylinder liners with varying diameters, ensuring versatility for manufacturers with diverse product lines. Additionally, it is equipped with state-of-the-art automation technology, allowing for seamless integration into existing production processes.In addition to its technical capabilities, the Liner Honing Machine is designed with user-friendly features that prioritize ease of operation and maintenance. This includes intuitive controls, accessible tooling components, and comprehensive safety measures. As a result, operators can maximize productivity and minimize downtime, ultimately leading to a more cost-effective manufacturing process.(Need remove brand name) prides itself on providing not only cutting-edge machinery but also on delivering comprehensive support to their customers. This includes training programs for machine operators, technical assistance for maintenance and troubleshooting, and readily available spare parts. By offering a complete package of products and services, the company ensures that their customers can fully leverage the potential of the Liner Honing Machine to optimize their production operations.The introduction of the Liner Honing Machine comes at a time when manufacturers are increasingly focusing on enhancing the quality and efficiency of their machining processes. With the growing emphasis on precision engineering in the automotive and heavy machinery sectors, the demand for advanced honing solutions has surged. (Need remove brand name) is well-positioned to address this demand with the introduction of the Liner Honing Machine, which is set to become an integral part of modern machining facilities.With a strong track record of providing reliable and innovative machining solutions, (Need remove brand name) has established itself as a trusted partner for manufacturers worldwide. The company's commitment to excellence, coupled with its dedication to customer satisfaction, has earned them a reputation as a leading provider of machining technology. The introduction of the Liner Honing Machine further cements their position in the industry and reinforces their promise to deliver superior products that meet the evolving needs of modern manufacturing.In conclusion, the Liner Honing Machine represents a significant advancement in the field of precision machining. With its cutting-edge technology, user-friendly design, and comprehensive support services, it is poised to set a new standard for honing engine cylinder liners. (Need remove brand name) continues to demonstrate its leadership in the industry by consistently introducing innovative solutions that empower manufacturers to achieve higher levels of efficiency and quality in their operations. As the demand for high-precision machining solutions continues to grow, the Liner Honing Machine is set to play a pivotal role in shaping the future of manufacturing.

High-Quality Single Cylinder Honing Machine for Precision Engine Work

The Single Cylinder Honing Machine is a cutting-edge piece of equipment that is revolutionizing the honing process in the manufacturing industry. This innovative machine is designed to improve the precision and efficiency of honing operations, making it an indispensable tool for companies seeking to enhance their production processes.The Single Cylinder Honing Machine is manufactured by a leading company in the industrial machinery sector. With a strong emphasis on innovation and quality, this company has earned a reputation for delivering cutting-edge solutions that meet the evolving needs of the manufacturing industry. Their commitment to excellence is evident in the design and performance of the Single Cylinder Honing Machine, which is setting new standards for honing precision and productivity.One of the key features of the Single Cylinder Honing Machine is its advanced technology, which allows for precise control and customization of the honing process. This level of precision ensures that each cylinder is honed to exact specifications, resulting in a superior finish and optimal performance. In addition, the machine is equipped with automated monitoring and feedback systems, which enable real-time adjustments and quality control during the honing process.The efficiency of the Single Cylinder Honing Machine is further enhanced by its high-speed performance and rapid tool change capabilities. This allows for streamlined production cycles and reduced downtime, ultimately improving overall productivity and cost-effectiveness for manufacturing operations. Additionally, the machine is designed for ease of use and maintenance, making it a practical and valuable asset for companies seeking to optimize their honing processes.The Single Cylinder Honing Machine is also designed with flexibility in mind, accommodating a wide range of cylinder sizes and materials. This versatility makes it a valuable investment for companies with diverse honing requirements, offering the ability to adapt to changing production demands and technological advancements. Furthermore, the machine’s robust construction and durable components ensure long-term reliability and performance, providing a sustainable solution for honing operations.The company behind the Single Cylinder Honing Machine is committed to providing comprehensive support and service to their customers, ensuring seamless integration and ongoing operational excellence. Their team of experienced professionals is available to assist with installation, training, and troubleshooting, leveraging their expertise to maximize the benefits of the Single Cylinder Honing Machine for each customer. Moreover, the company’s dedication to innovation drives continuous improvement and evolution of their products, ensuring that they remain at the forefront of industry advancements.As manufacturing processes continue to evolve, the demand for precision and efficiency in honing operations is increasingly critical. The Single Cylinder Honing Machine represents a significant advancement in honing technology, offering a state-of-the-art solution for companies seeking to elevate the quality and performance of their products. With its advanced capabilities, flexibility, and reliability, this innovative machine is poised to have a transformative impact on the manufacturing industry, delivering tangible benefits for companies and their customers alike.

Revolutionary Drilling Tool: Harnessing Advanced Technology for Unmatched Efficiency

Bta Drilling Tool Revolutionizes the Oil and Gas IndustryIn a world where efficiency and precision are paramount, Bta Drilling Tool has emerged as a game-changer in the oil and gas industry. With a firm commitment to innovation and cutting-edge technology, Bta Drilling Tool has revolutionized the way drilling operations are conducted. Their state-of-the-art tools, backed by decades of research and development, have elevated the industry standard to new heights, making drilling processes safer, faster, and more cost-effective.Founded in {year}, Bta Drilling Tool is a leading global provider of drilling equipment and solutions. Their extensive product portfolio caters to a wide range of drilling requirements, including oil and gas exploration, geothermal energy extraction, and mining operations. The company prides itself on its ability to deliver customized drilling solutions tailored to meet the unique needs of each customer, ensuring maximum productivity and efficiency.At the core of Bta Drilling Tool's success lies their steadfast commitment to pushing boundaries and exceeding expectations. Through continuous research and development, their team of experts has been able to develop some of the industry's most advanced drilling tools. From diamond core bits to downhole motors, Bta Drilling Tool has meticulously designed every product to deliver top-notch performance, durability, and reliability.One of the company's groundbreaking achievements is the development of their patented drilling technology known as {technology name}. This innovative technology has redefined the drilling process by significantly reducing drilling time while maintaining precision and accuracy. By optimizing the hydraulic system and improving the efficiency of drilling fluid circulation, Bta Drilling Tool's {technology name} ensures seamless drilling operations, thus saving time and resources for their customers.Moreover, Bta Drilling Tool's commitment to sustainability sets them apart from their competitors. Recognizing the need for environmentally-friendly drilling practices, the company has incorporated several eco-friendly features into their drilling tools. For instance, their advanced filtration systems help minimize the discharge of harmful drilling fluids into the environment, ensuring that natural habitats and water sources remain protected. This dedication to environmental stewardship has earned Bta Drilling Tool a reputation as a socially responsible and sustainable industry leader.Furthermore, Bta Drilling Tool has solidified its position as a global leader through strategic partnerships with major oil and gas companies. By collaborating with industry giants, Bta Drilling Tool gains access to invaluable expertise and resources, enabling them to develop cutting-edge solutions that address the evolving demands of the industry. These partnerships have also facilitated the exchange of knowledge and best practices, resulting in improved drilling techniques and increased operational efficiency.As the demand for energy continues to rise, Bta Drilling Tool remains at the forefront of the industry, constantly innovating and adapting to meet the evolving needs of their customers. With a dedicated team of engineers and technicians, the company is committed to staying ahead of the curve by investing in research and development. This commitment ensures that Bta Drilling Tool's customers always have access to the latest technology and solutions, empowering them to achieve their drilling objectives with utmost precision and efficiency.In conclusion, Bta Drilling Tool has revolutionized the oil and gas industry with its cutting-edge drilling solutions. Through innovative technologies such as {technology name}, the company has transformed the way drilling operations are conducted, making them safer, faster, and more cost-effective. With a commitment to sustainability and strategic partnerships, Bta Drilling Tool continues to lead the way in driving the industry forward. As the energy landscape continues to evolve, Bta Drilling Tool stands ready to meet the challenges and embrace the opportunities that lie ahead.

The Ultimate Guide to Single Cylinder Honing Machines: Everything You Need to Know

Single Cylinder Honing Machine: The Latest Addition to the Product Line of a Leading Manufacturing Company{Company Name}, a renowned manufacturer of precision tools and equipment, has recently announced the launch of their latest product, the Single Cylinder Honing Machine. This cutting-edge machine is designed to provide superior honing and surface finishing capabilities for a wide range of industrial applications. With over {number} years of experience in the manufacturing industry, {Company Name} has earned a reputation for delivering high-quality products that meet the diverse needs of their customers.The Single Cylinder Honing Machine is the result of extensive research and development efforts by {Company Name}'s team of skilled engineers and technicians. It is specifically engineered to offer precision honing for single cylinder engine blocks, ensuring optimal surface quality and dimensional accuracy. The machine boasts advanced features such as high-precision honing tools, a robust honing spindle, and a user-friendly control interface, making it an ideal choice for manufacturers seeking to enhance the performance and durability of their engine components.One of the key highlights of the Single Cylinder Honing Machine is its versatility, as it can accommodate a wide range of bore sizes and materials, including cast iron, steel, aluminum, and other alloys. This flexibility allows manufacturers to hone different types of engine blocks and cylinders with ease, thereby streamlining their production processes and improving overall efficiency. Additionally, the machine's automated honing cycle and integrated coolant system ensure consistent performance and prolonged tool life, contributing to cost savings and higher productivity.In line with {Company Name}'s commitment to customer satisfaction, the Single Cylinder Honing Machine is backed by comprehensive technical support and after-sales service. The company's team of experts is readily available to provide assistance with installation, training, and troubleshooting, ensuring that customers can maximize the potential of the machine and achieve optimal results in their operations. Furthermore, {Company Name} offers customizable tooling solutions and honing parameters to suit specific manufacturing requirements, further enhancing the value proposition of the Single Cylinder Honing Machine."We are thrilled to introduce the Single Cylinder Honing Machine to the market, as it represents a significant advancement in our product portfolio," said {Spokesperson Name}, the CEO of {Company Name}. "This machine exemplifies our dedication to innovation and excellence, and we are confident that it will empower our customers to elevate their honing processes and achieve superior surface finishes for their engine components."The launch of the Single Cylinder Honing Machine underscores {Company Name}'s ongoing commitment to meeting the evolving needs of the manufacturing industry and delivering cutting-edge solutions that drive operational efficiency and quality performance. With its proven track record of providing reliable and technologically advanced equipment, {Company Name} continues to be a trusted partner for businesses seeking to elevate their manufacturing capabilities and stay ahead in a competitive market landscape.To learn more about the Single Cylinder Honing Machine and other products offered by {Company Name}, interested parties can visit the company's website or contact their sales representatives for personalized consultations and demonstration sessions. As the manufacturing industry continues to evolve, {Company Name} remains at the forefront, providing innovative solutions that empower businesses to thrive and succeed in a dynamic market environment.

DIY Cylinder Honing Machine: A Budget-Friendly Option for Engine Maintenance

Home-based mechanics and small engine repair shops have a new tool in their arsenal with the introduction of the Homemade Cylinder Honing Machine, a cost-effective and efficient solution for honing engine cylinders.The Homemade Cylinder Honing Machine is designed and manufactured by an innovative company that specializes in creating practical and affordable tools for mechanics and hobbyists. With a dedication to quality and precision, they have developed a honing machine that can rival professional-grade equipment at a fraction of the cost.This new machine is perfect for small engine repair shops or DIY enthusiasts who want to hone engine cylinders without breaking the bank. It is compact and easy to use, making it a valuable addition to any workshop or garage. The homemade design allows for customization, giving users the ability to modify and improve the machine to suit their specific needs.The Homemade Cylinder Honing Machine is constructed from durable materials, ensuring longevity and reliability. The company takes pride in providing customers with tools that are built to last, and this honing machine is no exception. It is a solid investment for anyone looking to hone engine cylinders on a regular basis.One of the key features of this honing machine is its versatility. It is compatible with a wide range of engine sizes, making it a versatile tool for mechanics who work on various types of engines. Whether it's motorcycles, small cars, or lawnmowers, the Homemade Cylinder Honing Machine can handle the job with ease.Furthermore, the company offers excellent customer support and technical assistance to ensure that customers are able to use the honing machine properly and achieve the best results. They are committed to providing a positive user experience, and that includes offering guidance and advice for novice users.The Homemade Cylinder Honing Machine is also designed with safety in mind. The company understands the importance of protecting users from potential hazards, and they have incorporated safety features into the design of the honing machine. This gives users peace of mind while working with the equipment, knowing that they are protected from harm.In addition to its practicality and affordability, the Homemade Cylinder Honing Machine is also environmentally friendly. It reduces the need for outsourcing cylinder honing work, which can result in lower carbon emissions and fuel consumption. This aligns with the company's commitment to sustainability, making the honing machine a responsible choice for conscientious mechanics and hobbyists.As an added bonus, the company provides a warranty for the Homemade Cylinder Honing Machine, giving customers added assurance that they are investing in a reliable and well-supported tool. This is a strong demonstration of the company's confidence in their product, and it gives customers the confidence to invest in the honing machine without hesitation.Overall, the Homemade Cylinder Honing Machine is a game-changer for small engine repair shops and home-based mechanics. With its affordability, versatility, durability, and commitment to user safety and support, it is a standout tool in the world of engine repair equipment. The company behind this innovative machine has once again proven their dedication to providing practical and affordable tools for mechanics, and the Homemade Cylinder Honing Machine is a testament to their ingenuity and commitment to quality.

Revolutionary CNC Technology Advancing Deep Hole Drilling Techniques

Title: Pushing the Boundaries of Precision Machining: Advanced Deep Hole Drilling CNC Technology Revolutionizes ManufacturingIntroduction:In an ever-evolving world of manufacturing, companies are constantly seeking new and innovative solutions to enhance precision and efficiency in production processes. One groundbreaking tool that has revolutionized the way manufacturers push the boundaries of precision machining is the advanced Deep Hole Drilling CNC technology. In this article, we will shed light on the power and potential of this cutting-edge instrument and explore how it has transformed the way companies operate.Advanced Deep Hole Drilling CNC: Redefining Precision Machining:Deep Hole Drilling CNC, a technology developed by {company}, implements an advanced drilling technique that allows manufacturers to achieve the most intricate and precise holes in a wide range of materials, including metals, composites, and alloys. Unlike traditional drilling methods, this state-of-the-art CNC technology has revolutionized the manufacturing industry, enabling companies to produce complex and high-quality components with unprecedented accuracy and efficiency.Unveiling the Features and Capabilities:By integrating a combination of technological advancements including computer numerical control (CNC) programming, adaptive tool control systems, and high-pressure coolant systems, Deep Hole Drilling CNC has surpassed all existing limitations in precision machining. Some prominent features and capabilities include:1. Unparalleled Accuracy: Deep Hole Drilling CNC employs advanced motion control systems, including high-precision linear guides and servomotors, providing exceptional accuracy and repeatability. The technology eliminates the risk of inaccuracies caused by human error, ensuring precision in every hole produced.2. Enhanced Productivity: With the ability to perform multiple drilling operations in a single setup, the Deep Hole Drilling CNC technology significantly reduces production time. Its capability to produce holes of varying depths, diameters, and complex geometries in a single pass minimizes the need for extensive repositioning, leading to enhanced productivity levels.3. Optimal Cooling Mechanisms: Deep Hole Drilling CNC utilizes high-pressure coolant systems that effectively remove chips, cool the cutting edges, and lubricate the workpiece. This feature minimizes heat generation while prolonging the lifespan of the tools, resulting in reduced downtime and improved overall efficiency.4. Uncompromised Flexibility: The technology offers immense flexibility, accommodating a wide range of applications and specifications. Deep Hole Drilling CNC is compatible with various materials such as steel, aluminum, and even hardened alloys, making it an ideal solution for a multitude of industries, from aerospace to automotive, from biomedical to oil and gas.Transforming Manufacturing Operations:With its unrivaled precision and efficiency, Deep Hole Drilling CNC technology has transformed manufacturing operations, bringing numerous benefits to companies across different industries. Some notable advantages include:1. Cost Reduction: By minimizing human intervention, reducing setup times, and eliminating the need for multiple drilling passes, this advanced technology significantly reduces labor costs and enhances overall production efficiency. Manufacturers can achieve higher outputs without compromising quality.2. Superior Quality: Deep Hole Drilling CNC ensures superior hole quality, surpassing conventional drilling methods. The technology guarantees precise roundness, improved surface finish, and reduced burr formation, meeting the stringent quality requirements of the most demanding industries.3. Competitive Edge: Adopting Deep Hole Drilling CNC technology grants companies a competitive edge in the market. Manufacturers can offer unique and specialized components with unmatched precision, attracting new clients and expanding their customer base.4. Sustainability: The environmental impact of manufacturing processes is reduced through the use of Deep Hole Drilling CNC. Optimized coolant systems and the elimination of material waste contribute to a more sustainable production environment.Conclusion:Deep Hole Drilling CNC technology, developed by {company}, is a game-changer in the field of precision machining. Through advanced features and capabilities, this cutting-edge technology introduces unprecedented levels of accuracy, efficiency, and productivity to the manufacturing industry. With its ability to transform operations, reduce costs, and ensure superior quality, Deep Hole Drilling CNC has become an indispensable tool for manufacturers seeking to stay ahead in the ever-evolving world of advanced machining.