High Precision Gun Drilling Tools for Efficient Machining

By:Admin

Gun Drilling Tools is excited to announce the launch of a new line of high-precision drilling tools. With the company's decades of experience in the industry, this new line is set to revolutionize the way companies approach deep hole drilling processes.

Gun Drilling Tools is a leading manufacturer of drilling tools and has built a strong reputation for delivering high-quality products and exceptional customer service. With a focus on innovation and continuous improvement, the company has consistently pushed the boundaries of what is possible in the field of deep hole drilling.

The new line of high-precision drilling tools is the result of extensive research and development, and the company's commitment to meeting the evolving needs of its customers. These tools have been designed to provide unparalleled precision and performance, helping manufacturers achieve greater accuracy and efficiency in their drilling processes.

One of the key features of the new line is the advanced cutting-edge technology that has been integrated into the tools. This technology allows for smoother and more consistent drilling, reducing the risk of errors and yielding higher-quality results. Additionally, the tools have been engineered to withstand the demands of high-speed drilling, ensuring durability and longevity in even the most challenging of operating conditions.

Furthermore, the new line of drilling tools has been manufactured to the highest industry standards, with a focus on quality and reliability. Each tool undergoes rigorous testing and inspection processes to ensure that it meets the company's exacting specifications. This commitment to quality is a reflection of Gun Drilling Tools' dedication to providing its customers with products that they can trust and rely on.

In addition to the exceptional performance of the tools, customers can also benefit from Gun Drilling Tools' extensive technical expertise and support. The company's team of experienced engineers and technicians is available to provide guidance and assistance to customers, helping them optimize their drilling processes and achieve the best results possible.

The launch of the new line of high-precision drilling tools is a significant milestone for Gun Drilling Tools, and the company is confident that these tools will have a positive impact on the industry. With their focus on precision, performance, and reliability, these tools have the potential to transform the way companies approach deep hole drilling, ultimately leading to improved productivity and cost savings.

For more information about Gun Drilling Tools and its new line of high-precision drilling tools, please visit the company's website or contact their customer service team. With their expertise and dedication to excellence, Gun Drilling Tools is well-equipped to meet the needs of manufacturers across a wide range of industries, and the launch of these new tools is a testament to their continued commitment to innovation and customer satisfaction.

Company News & Blog

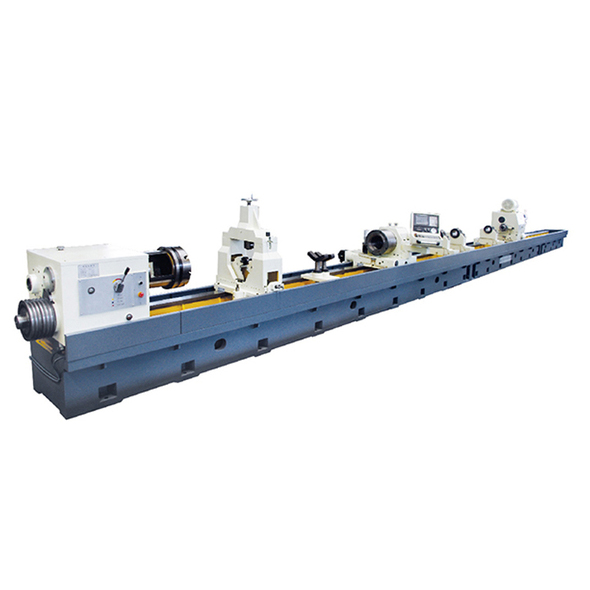

High-Performance Heavy Duty Deep Hole Drilling And Boring Machine

Heavy Duty Deep Hole Drilling And Boring Machine Revolutionizing Manufacturing IndustryInnovation in manufacturing technology has always been crucial to the growth and success of various industries. One such innovation that has taken the manufacturing industry by storm is the introduction of the Heavy Duty Deep Hole Drilling and Boring Machine by a leading company.This state-of-the-art machine has brought about a radical shift in the traditional manufacturing processes, offering unparalleled precision, efficiency, and productivity. The combined capabilities of drilling and boring in a single machine have significantly enhanced the manufacturing capabilities of various industries, including aerospace, automotive, energy, and defense.The Heavy Duty Deep Hole Drilling and Boring Machine, developed by the company, boasts a robust and durable construction, making it capable of handling the most demanding drilling and boring tasks. It is equipped with advanced features and cutting-edge technology, setting new benchmarks for accuracy and performance in the manufacturing industry.With its ability to drill and bore deep holes with exceptional precision, the machine has become an indispensable tool for the production of components and parts that require high levels of accuracy and reliability. Its versatility and adaptability have positioned it as a go-to solution for a wide range of applications across different industrial sectors.The company behind this groundbreaking machine has a long-standing reputation for delivering innovative and reliable manufacturing solutions. With a strong focus on research and development, they have consistently pushed the boundaries of technology, introducing cutting-edge products that set new industry standards.The Heavy Duty Deep Hole Drilling and Boring Machine is a testament to the company's commitment to delivering state-of-the-art solutions that cater to the evolving needs of the manufacturing industry. Its introduction has not only met the current demands of advanced manufacturing but has also paved the way for future developments in the field.One of the key advantages of this revolutionary machine is its ability to optimize production processes, significantly reducing lead times and production costs. The precision and efficiency it offers have enabled manufacturers to streamline their operations, minimize waste, and produce high-quality components at a faster pace.Moreover, the machine's user-friendly interface and advanced automation features have made it accessible to a wide range of operators, eliminating the need for extensive training and reducing the risk of human error. This has further cemented its status as an invaluable asset for manufacturers seeking to enhance their productivity and competitiveness.The Heavy Duty Deep Hole Drilling and Boring Machine has already garnered widespread acclaim within the manufacturing community, with industry experts praising its superior performance and versatility. Its impact on the production of complex components and parts has been nothing short of transformative, enabling manufacturers to achieve levels of precision and quality that were previously unattainable.As the manufacturing industry continues to evolve, the demand for advanced drilling and boring solutions that can meet the increasing requirements of precision engineering and high-performance manufacturing will only grow. The company's Heavy Duty Deep Hole Drilling and Boring Machine is poised to play a pivotal role in shaping the future of manufacturing, driving efficiency, innovation, and excellence across various sectors.In conclusion, the introduction of the Heavy Duty Deep Hole Drilling and Boring Machine by the company has marked a significant milestone in the manufacturing industry. Its unrivaled capabilities, advanced features, and unmatched performance have positioned it as a game-changer, revolutionizing the way components and parts are manufactured. As an embodiment of cutting-edge technology and precision engineering, this machine holds immense potential in shaping the future of manufacturing, setting new benchmarks for quality, efficiency, and productivity.

Discover the Benefits of Gun Drilling for Precision Machining

Gun Drilling is a specialized machining process used to create deep, straight holes in a variety of materials. This highly precise method is often used in the manufacturing of firearms, as well as in the production of parts for industries such as aerospace, automotive, and medical. The process involves using a long, thin cutting tool to remove material from the workpiece, while also providing coolant to reduce heat and prevent the formation of chips.One company that has established itself as a leader in the field of Gun Drilling is {}. With a wealth of experience and expertise in the manufacturing industry, they have developed a reputation for delivering high-quality, reliable gun drilling solutions to their customers.Founded in {}, the company has grown to become a trusted partner for many businesses looking for precise and efficient gun drilling services. Their state-of-the-art facility is equipped with the latest technology and machinery, allowing them to tackle even the most complex drilling challenges with ease.The company's team of skilled engineers and technicians are dedicated to providing innovative solutions to their customers' needs. By combining cutting-edge technology with years of industry knowledge, they are able to deliver gun drilling services that meet the highest standards of quality and precision.One of the key advantages of choosing {} for gun drilling services is their ability to work with a wide range of materials. Whether it's steel, aluminum, titanium, or other exotic alloys, their team has the expertise to provide accurate, consistent results every time.In addition to their expertise in gun drilling, the company also offers a variety of other machining services to meet the diverse needs of their customers. From milling and turning to honing and grinding, they have the capabilities to handle a wide range of machining tasks with precision and efficiency.Another major strength of {} is their commitment to customer satisfaction. They work closely with each client to understand their specific requirements, and then develop customized solutions to meet those needs. This dedication to understanding and meeting customer needs has earned them a loyal and satisfied customer base.As the demand for precision machining continues to grow in various industries, {} is well-positioned to meet this demand with their advanced capabilities and expertise in gun drilling and other machining services. With a focus on quality, efficiency, and customer satisfaction, they are poised to remain a leader in the industry for years to come.In conclusion, Gun Drilling is a critical process in the manufacturing of a wide range of products, and {} has established itself as a top provider of this specialized service. With their advanced technology, skilled team, and commitment to customer satisfaction, they are well-equipped to continue meeting the needs of their customers for precise and efficient gun drilling solutions. Whether it's for firearms, aerospace components, medical devices, or other applications, {} stands ready to deliver exceptional results for all their customers' drilling needs.

Specialized Deep Hole Drilling Techniques for Enhanced Precision

Deep Hole Drilling, a leading provider of specialized drilling solutions, has announced groundbreaking advancements in their drilling technology. This company, with a history of innovation and a commitment to excellence, is taking the drilling industry to new heights.With over 30 years of experience, Deep Hole Drilling has established itself as a premier provider of deep hole drilling services. The company has a proven track record of delivering high-quality, precise results for a wide range of industries, including aerospace, automotive, defense, and medical. Their state-of-the-art facilities and cutting-edge equipment allow them to tackle even the most challenging drilling projects with precision and efficiency.One of the key factors that sets Deep Hole Drilling apart from its competitors is its commitment to research and development. The company invests heavily in developing and refining its drilling technology, constantly seeking new ways to improve performance and expand capabilities. This dedication to innovation has led to the development of several breakthrough technologies that are revolutionizing the drilling industry.One such advancement is the development of a new drilling method that allows for faster and more precise drilling of deep holes. This innovative technology has been carefully engineered to deliver unparalleled performance, enabling Deep Hole Drilling to tackle even the most complex drilling projects with ease. With this new method, the company is able to achieve deeper, straighter, and more accurate holes, setting a new standard for drilling precision.In addition to their advancements in drilling technology, Deep Hole Drilling is also dedicated to sustainability and environmental responsibility. The company has implemented numerous measures to minimize its environmental impact, including the use of eco-friendly drilling fluids and the adoption of energy-efficient drilling processes. By prioritizing sustainability, Deep Hole Drilling is not only reducing its environmental footprint but also helping its customers meet their own sustainability goals.Furthermore, Deep Hole Drilling is committed to upholding the highest industry standards for quality and safety. The company has stringent quality control measures in place to ensure that every drilling project meets the most rigorous specifications and requirements. Additionally, Deep Hole Drilling prioritizes the safety of its employees and the surrounding community, implementing comprehensive safety protocols and procedures to minimize risk and ensure a safe working environment.With its unrivaled drilling technology, commitment to sustainability, and dedication to quality and safety, Deep Hole Drilling is positioned as a leader in the drilling industry. As the company continues to push the boundaries of drilling technology, it is poised to revolutionize the way deep hole drilling is done and set new industry standards for performance and precision.Deep Hole Drilling's advancements in drilling technology are not only reshaping the industry but are also opening up new possibilities for its customers. With the ability to achieve deeper, straighter, and more accurate holes, Deep Hole Drilling is empowering its customers to pursue new opportunities and tackle even the most challenging drilling projects with confidence.As the company looks to the future, it remains committed to innovation, sustainability, quality, and safety. Deep Hole Drilling is dedicated to pushing the boundaries of what is possible in drilling technology and continuing to deliver exceptional results for its customers. With its unparalleled expertise and cutting-edge technology, Deep Hole Drilling is well-equipped to lead the industry into a new era of drilling excellence.

Powerful Electric Drill Gun Machine for High-Performance Drilling Jobs

Drill Gun Machine Revolutionizing the Construction IndustryIn recent years, the construction industry has seen a significant technological advancement that has revolutionized the way projects are executed. One of the most notable contributions to this revolution is the Drill Gun Machine (DGM). This innovative piece of equipment has not only streamlined construction processes but has also improved overall efficiency and safety on the job site.The DGM is the brainchild of a leading construction equipment manufacturer that specializes in providing high-quality and reliable machinery for various construction applications. With a strong focus on innovation and customer satisfaction, the company has been at the forefront of developing advanced solutions that meet the evolving needs of the industry.This state-of-the-art Drill Gun Machine is a powerful and versatile tool that has become an essential asset for construction professionals around the world. With its precision engineering and ergonomic design, the DGM offers unmatched performance and convenience, making it a game-changer in the construction sector.Equipped with robust motors and advanced drilling mechanisms, the DGM is capable of handling a wide range of drilling tasks with ease. Whether it's boring holes in concrete, masonry, or metal, this machine delivers exceptional results with superior accuracy and speed. Its adjustable speed settings and torque control ensure that users have complete control over the drilling process, allowing for precise and efficient work.Furthermore, the DGM features a compact and lightweight design, making it easy to maneuver in tight spaces and challenging environments. This level of portability has significantly enhanced the overall productivity of construction crews, enabling them to complete tasks in record time without compromising on quality.Another key highlight of the DGM is its focus on safety. The machine is equipped with advanced safety features, including automatic shutoff mechanisms and ergonomic handles, to minimize the risk of accidents and injuries on the job site. This demonstrates the manufacturer's commitment to providing reliable and secure equipment that prioritizes the well-being of workers.The DGM is also designed to be low-maintenance, reducing downtime and ensuring continuous operation on construction sites. Its durable construction and high-quality components make it a long-term investment for construction companies, offering a reliable and cost-effective solution for their drilling needs.The impact of the DGM has been felt across various construction projects, ranging from residential developments to large-scale infrastructure undertakings. By streamlining drilling operations and improving efficiency, the machine has contributed to significant time and cost savings for construction firms, ultimately translating into better project outcomes and client satisfaction.Moreover, the company behind the DGM has established a strong support network to ensure that customers receive the necessary training, maintenance, and technical assistance for their equipment. This dedication to customer service has further solidified the reputation of the manufacturer as a trusted partner in the construction industry.Looking ahead, the company continues to push the boundaries of innovation, with ongoing research and development efforts to enhance the capabilities of the DGM and introduce new solutions that address the evolving needs of construction professionals. By collaborating with industry experts and incorporating feedback from users, the manufacturer remains committed to delivering cutting-edge equipment that drives progress in the construction sector.In conclusion, the Drill Gun Machine has emerged as a transformative technology in the construction industry, offering unparalleled performance, safety, and efficiency. With its innovative design and focus on customer satisfaction, it has set a new standard for drilling equipment and has undoubtedly left a lasting impact on the way construction projects are executed. As the industry continues to evolve, the DGM and its manufacturer will undoubtedly play a pivotal role in shaping the future of construction.

The Latest Innovation in Honing Machine Technology

Honing Machine: The Latest Innovation in Precision MachiningIn the world of precision machining, accuracy and precision are of utmost importance. Honing machines are a critical tool used in the manufacturing industry to achieve the level of precision necessary for high-quality products. These machines are designed to create a finely finished surface on a workpiece, ensuring that the dimensions and geometry meet the required specifications. The honing process involves the use of abrasive stones to remove small amounts of material from the surface of the workpiece, resulting in a precise and smooth finish.One of the leading manufacturers of honing machines, {company name}, is known for its innovative and high-quality products. With a strong focus on research and development, the company has continuously pushed the boundaries of honing technology, introducing new and advanced features to meet the evolving needs of the industry. Their honing machines are widely used in various sectors such as automotive, aerospace, hydraulics, and mold making, delivering exceptional results and performance.The latest honing machine from {company name} is a testament to their commitment to innovation and excellence. This new machine, known as the {model name}, is equipped with state-of-the-art technology and features that set it apart from its predecessors and competitors. With enhanced precision control and improved efficiency, the {model name} offers a level of performance that is unmatched in the industry.One of the key features of the {model name} is its advanced control system, which allows for highly accurate and consistent honing results. The machine is equipped with cutting-edge sensors and monitoring devices that enable real-time feedback and adjustments, ensuring that the honing process is optimized for each specific workpiece. This level of precision control is essential for meeting the tight tolerances and surface finish requirements demanded by modern manufacturing standards.In addition to its precision control, the {model name} is also designed for versatility and flexibility. The machine offers a wide range of honing capabilities, allowing for the processing of various workpiece sizes and materials. This versatility makes the {model name} a valuable investment for manufacturers who work with diverse and complex parts, as it can accommodate a wide range of honing needs without compromising on quality or performance.Furthermore, the {model name} is designed with productivity in mind. The machine features a high-speed honing spindle and advanced automation capabilities that significantly reduce cycle times and increase throughput. This allows manufacturers to improve their overall efficiency and meet production demands with ease, making the {model name} a valuable asset for increasing operational effectiveness.{company name} is also committed to ensuring that their honing machines are user-friendly and easy to maintain. The {model name} is designed with a user-friendly interface and intuitive controls, making it accessible to both experienced operators and those new to honing technology. Additionally, the machine is engineered for easy maintenance and serviceability, minimizing downtime and maximizing productivity.As the manufacturing industry continues to demand higher levels of precision and efficiency, technological advancements such as the {model name} are crucial for meeting these demands. {company name} has once again proven itself as a leader in honing technology, setting the standard for precision machining with their latest innovation.With its advanced control, versatility, productivity, and user-friendly design, the {model name} honing machine has set a new benchmark for precision machining equipment. Manufacturers across various industries can rely on {company name} to deliver exceptional quality and performance that exceeds expectations, solidifying their position as a trusted partner in the world of precision manufacturing.

Advanced Automatic Honing Machine for Precision Engineering

CNC Automatic Honing Machine Revolutionizes Finishing ProcessesWith the constant evolution of technology in manufacturing, businesses are constantly seeking innovative solutions to improve their production processes. One such solution comes in the form of the CNC Automatic Honing Machine, a cutting-edge piece of equipment designed to revolutionize the finishing and honing processes in the manufacturing industry.The CNC Automatic Honing Machine, also known as the {brand name} honing machine, is equipped with advanced automated features that make it the ideal choice for businesses looking to streamline their honing operations. This state-of-the-art machine is capable of achieving precise and consistent results, making it a valuable asset for companies looking to improve the quality and efficiency of their production processes.The {brand name} honing machine is designed to accommodate a wide range of applications, including the honing of cylinders, sleeves, and other components used in the manufacturing of engines, hydraulics, and other industrial equipment. Its high level of precision and efficiency make it an indispensable tool for businesses operating in the automotive, aerospace, and hydraulic industries.In addition to its advanced automated features, the {brand name} honing machine is also equipped with a user-friendly interface that allows for easy operation and monitoring. This ensures that businesses can achieve optimal results with minimal training and oversight, making it an ideal solution for companies looking to improve their productivity and reduce labor costs.One of the key advantages of the {brand name} honing machine is its ability to deliver exceptional results with minimal manual intervention. This not only reduces the risk of human error but also allows businesses to achieve a higher level of consistency and precision in their honing processes. As a result, businesses can expect to see a significant improvement in the quality of their finished products, leading to greater customer satisfaction and loyalty.The {brand name} honing machine is the brainchild of {company name}, a leading manufacturer and provider of innovative honing solutions for the manufacturing industry. With a strong focus on research and development, {company name} is committed to delivering cutting-edge technologies that empower businesses to achieve new levels of efficiency and quality in their production processes.The company's dedication to innovation and quality is reflected in the design and engineering of the {brand name} honing machine. By leveraging the latest advancements in automation and precision engineering, {company name} has created a solution that addresses the evolving needs of modern manufacturing businesses.In addition to its technical capabilities, {company name} also provides comprehensive support and training for businesses looking to integrate the {brand name} honing machine into their production processes. This ensures that businesses can maximize the potential of the machine and achieve the best possible results, ultimately leading to improved productivity and profitability.The introduction of the CNC Automatic Honing Machine marks a significant milestone in the evolution of honing and finishing processes in the manufacturing industry. With its advanced automated features, user-friendly interface, and exceptional precision, the {brand name} honing machine is poised to become a game-changer for businesses looking to elevate their production processes to new heights of quality and efficiency.In conclusion, the {brand name} honing machine represents a new era of innovation and efficiency in the manufacturing industry. With its advanced technology and user-friendly design, it is set to revolutionize honing and finishing processes, empowering businesses to achieve superior results with minimal manual intervention. As manufacturing businesses continue to seek ways to increase productivity and improve quality, the {brand name} honing machine offers a compelling solution that sets new standards for precision and consistency.

Deep Hole Drilling for Precision Machining: What You Need to Know

Precision Deep Hole Drilling, also known as Gun Drilling, is a specialized drilling process that requires high precision and accuracy. This process is commonly used in the manufacturing of components for industries such as aerospace, automotive, medical, and defense.The importance of precision deep hole drilling cannot be overstated. The ability to create deep, straight, and accurate holes is crucial for the production of many complex components. With the demand for high precision parts increasing, the need for precision deep hole drilling has also grown significantly.Company {} is a leading provider of precision deep hole drilling services. With state-of-the-art equipment and highly skilled technicians, the company has built a reputation for delivering high-quality and reliable deep hole drilling solutions to its clients. {} has developed a deep understanding of the intricacies involved in precision deep hole drilling, allowing them to tackle even the most challenging projects with confidence and expertise.One of the key aspects that sets {} apart from its competitors is its commitment to innovation. The company is constantly investing in the latest technologies and techniques to improve its deep hole drilling processes. This dedication to innovation has allowed {} to stay at the forefront of the industry and consistently deliver superior results to its clients.In addition to its technological capabilities, {} is also known for its exceptional customer service. The company works closely with its clients to understand their specific needs and requirements, ensuring that the final product meets their exact specifications. This personalized approach has earned {} the trust and loyalty of its clients, many of whom return to the company for their deep hole drilling needs time and time again.Furthermore, {} is dedicated to maintaining the highest standards of quality and safety in all of its operations. The company adheres to strict quality control measures throughout the deep hole drilling process, ensuring that the final product meets the most stringent industry standards. Additionally, {} prioritizes the safety of its employees and invests in ongoing training and development to ensure a safe working environment.The deep hole drilling services offered by {} are wide-ranging and versatile. Whether it's for the production of complex aerospace components, high-performance automotive parts, precision medical devices, or critical defense equipment, {} has the expertise and capabilities to deliver outstanding results. With the ability to drill holes ranging from 0.5mm to 250mm in diameter and depths of up to 6 meters, {} can accommodate a diverse range of deep hole drilling needs.The applications of precision deep hole drilling are countless, and {} has proven its ability to tackle a wide variety of projects with skill and precision. Whether it's creating cooling channels in injection molds, producing hydraulic cylinders, manufacturing rifle barrels, or any other specialized deep hole drilling requirement, {} has the expertise and experience to deliver exceptional results.As the demand for high precision components continues to grow, the need for reliable and experienced precision deep hole drilling services has never been greater. With its commitment to innovation, exceptional customer service, and dedication to quality and safety, {} is well-positioned to meet the evolving needs of the industry and continue to be a leader in the field of precision deep hole drilling.

Highly Efficient Long Hole Drilling Machine Unveiled for Mining Operations

Long Hole Drilling Machine Revolutionizes Mining IndustryThe mining industry has evolved significantly over the years, with technological advancements playing a crucial role in driving efficiency and productivity. One of the latest innovations to make its mark in the industry is the Long Hole Drilling Machine, which has been developed by a leading mining equipment manufacturer.This state-of-the-art machine has been designed to perform long hole drilling in underground mining operations, offering a more efficient and cost-effective solution compared to traditional drilling methods. Its advanced capabilities have quickly garnered attention from mining companies around the world, paving the way for a new era in underground mining.The Long Hole Drilling Machine boasts a range of features that set it apart from conventional drilling equipment. Its high-powered hydraulic system allows for faster and more precise drilling, while its automated functions minimize the need for manual intervention, reducing the risk of human error. Additionally, the machine's compact design enables it to navigate through narrow tunnels and reach depths that were previously unattainable with traditional drilling equipment.In addition to its impressive capabilities, the Long Hole Drilling Machine also prioritizes safety and environmental sustainability. Its integrated safety mechanisms ensure the well-being of operators, while its efficient energy consumption minimizes the machine's impact on the environment. These features have earned the machine accolades from industry experts, further solidifying its reputation as a game-changer in the mining sector.The company behind the development of the Long Hole Drilling Machine has established itself as a leader in the field of mining equipment manufacturing. With a history of delivering cutting-edge solutions to the industry, the company has gained the trust of mining companies worldwide, earning a reputation for reliability and innovation.In line with its commitment to excellence, the company has invested heavily in research and development to bring the Long Hole Drilling Machine to fruition. Through collaboration with industry experts and extensive testing in real-world mining scenarios, the company has ensured that the machine meets the highest standards of quality and performance.Moreover, the company has placed a strong emphasis on customer satisfaction, offering comprehensive technical support and training programs to mining companies that adopt the Long Hole Drilling Machine. By providing ongoing assistance and maintenance services, the company aims to maximize the machine's operational efficiency and longevity, further enhancing its value to its users.The introduction of the Long Hole Drilling Machine comes at a time when the mining industry is seeking innovative solutions to improve productivity and minimize costs. With its ability to streamline the drilling process and unlock new possibilities in underground mining, the machine is poised to bring about a significant shift in the way mining operations are conducted.As mining companies continue to embrace the Long Hole Drilling Machine, the industry can expect to witness notable improvements in operational efficiency and safety. The machine's advanced capabilities have the potential to redefine underground mining practices, setting a new standard for productivity and sustainability.In conclusion, the Long Hole Drilling Machine has emerged as a groundbreaking innovation that has the power to revolutionize the mining industry. With its cutting-edge technology, commitment to safety, and environmental consciousness, the machine is a testament to the potential of technological advancements to drive progress in the field of mining. As the industry continues to evolve, the Long Hole Drilling Machine stands as a beacon of innovation, offering a glimpse into the future of underground mining.

Innovative Deep Drilling Machine Offers Advanced Capabilities for Industrial Applications

For immediate release[Company Name]'s Deep Drilling Machine Now Available for Enhanced Exploration[City, Date] - [Company Name], the leading provider of innovative drilling solutions, is proud to introduce its latest offering - the Deep Drilling Machine. This state-of-the-art equipment is designed to revolutionize the way drilling operations are conducted, offering advanced technology and unprecedented precision for enhanced exploration and resource extraction.The Deep Drilling Machine represents a significant step forward in the field of drilling technology. With its robust construction and cutting-edge features, this machine is capable of reaching depths that were previously inaccessible, opening up new possibilities for exploration and development in various industries, including mining, oil and gas, and geothermal energy.One of the key highlights of the Deep Drilling Machine is its unparalleled drilling capacity. Equipped with a powerful hydraulic system and advanced drilling tools, this machine can bore through hard rock formations and challenging geological conditions with remarkable ease and efficiency. This capability not only streamlines the drilling process but also reduces downtime and operational costs, making it a cost-effective solution for companies looking to optimize their drilling operations.In addition to its impressive drilling capabilities, the Deep Drilling Machine is also equipped with cutting-edge safety features and environmental controls. With built-in sensors and monitoring systems, the machine ensures a safe and secure working environment for operators, minimizing the risk of accidents and ensuring compliance with industry regulations. Furthermore, the machine's advanced filtration and waste management systems help mitigate the environmental impact of drilling activities, making it a responsible and sustainable choice for resource extraction.“At [Company Name], we are dedicated to pushing the boundaries of drilling technology and providing our customers with the tools they need to thrive in a rapidly evolving industry,” said [Company Spokesperson]. “The Deep Drilling Machine is the culmination of years of research and development, and we are confident that it will set a new standard for deep drilling operations.”In addition to its technical prowess, the Deep Drilling Machine is backed by [Company Name]'s renowned technical support and service. With a global network of service centers and highly trained technicians, the company is committed to providing prompt assistance and maintenance, ensuring that the machine operates at peak performance throughout its service life.The Deep Drilling Machine is now available for purchase, and [Company Name] encourages interested parties to contact their local representative for more information on product specifications, pricing, and customization options.About [Company Name]:[Company Name] is a leading provider of drilling solutions for a wide range of industries, including mining, oil and gas, geothermal energy, and construction. With a focus on innovation and quality, the company has earned a reputation for delivering cutting-edge equipment and exceptional customer service. Headquartered in [City], [Company Name] operates globally, serving clients in diverse markets with a comprehensive range of drilling products and services.For media inquiries or further information, please contact:[Company Spokesperson][Title][Company Name][Phone number][Email]-END-

The Ultimate Guide to Deep Hole Gundrill Techniques and Applications

Deep Hole Gundrill, a leading provider of precision deep hole drilling solutions, has been making waves in the manufacturing industry with its innovative technology and unmatched expertise. With a focus on delivering high-quality results and exceeding customer expectations, the company has established itself as a go-to source for deep hole drilling needs.The company’s success can be attributed to its state-of-the-art equipment and a team of highly skilled professionals who are dedicated to pushing the boundaries of what is possible in deep hole drilling. Deep Hole Gundrill has made substantial investments in the latest technology, ensuring that it remains at the forefront of the industry and can meet the evolving needs of its customers.One of the company’s standout offerings is its deep hole gundrilling services, which are in high demand across a range of industries. Deep hole gundrilling is a specialized process that involves drilling straight, deep holes in various materials, including metal, plastic, and composites. This process is essential for the development and production of a wide range of products, including hydraulic cylinders, injection mold components, and firearm barrels, among others.Deep Hole Gundrill has distinguished itself in the market by offering precision deep hole gundrilling services that are tailored to meet the specific needs of its customers. The company has the capabilities to accommodate varying hole diameters, depths, and specifications, ensuring that each project is completed with the utmost accuracy and precision.The company’s deep hole gundrilling services are bolstered by its commitment to quality and customer satisfaction. Deep Hole Gundrill has implemented strict quality control measures to ensure that each drilling project meets the highest standards. Additionally, the company’s team of experts works closely with customers to understand their unique requirements and provide personalized solutions that deliver exceptional results.With a focus on continuous improvement and innovation, Deep Hole Gundrill has developed a reputation for tackling complex drilling challenges and delivering superior outcomes. The company prides itself on its ability to think outside the box and develop cutting-edge solutions that push the boundaries of what is possible in deep hole drilling.In addition to its deep hole gundrilling services, Deep Hole Gundrill offers a comprehensive range of supplementary capabilities, including honing, boring, and machining. This allows the company to provide a full-service approach to deep hole drilling, catering to the diverse needs of its customers and delivering a complete solution under one roof.Despite its success and growth, Deep Hole Gundrill remains committed to its core values of integrity, reliability, and excellence. The company places a strong emphasis on building long-lasting relationships with its customers, suppliers, and partners, fostering a collaborative environment that drives mutual success.As the manufacturing industry continues to evolve, Deep Hole Gundrill is poised to remain at the forefront of deep hole drilling technology, delivering innovative solutions that set new benchmarks for precision and performance. With its unwavering commitment to quality, a passion for innovation, and a customer-centric approach, the company is well-positioned to meet the dynamic needs of the market and continue its trajectory of growth and success.With a proven track record of delivering exceptional results and an unwavering dedication to pushing the boundaries of what is possible in deep hole drilling, Deep Hole Gundrill has solidified its position as a market leader and a trusted partner for precision drilling needs. As the company looks toward the future, its focus on innovation, quality, and customer satisfaction will continue to drive its success and ensure its standing as a go-to source for deep hole drilling solutions.