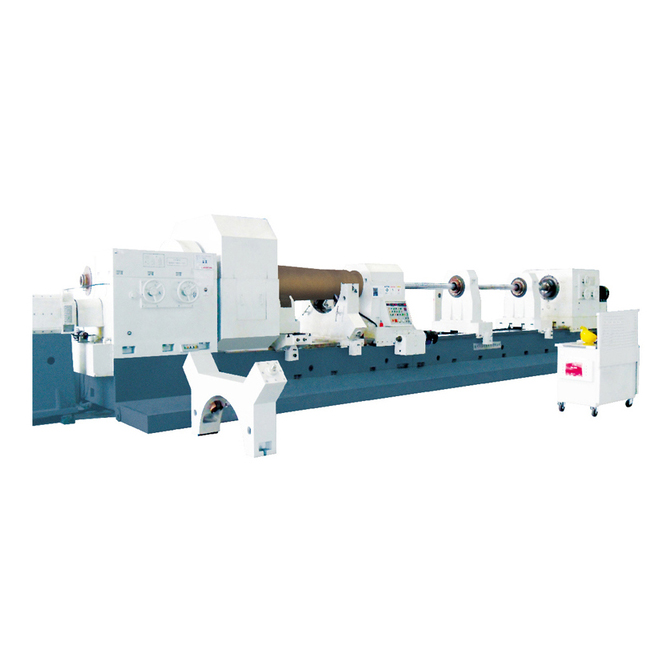

High-quality Pistol Drilling Machine for Efficient and Precise Drilling Operations

By:Admin

The manufacturing industry is constantly evolving, with new technologies and equipment emerging to streamline processes and improve efficiency. One such innovation is the Pistol Drilling Machine, a cutting-edge tool that has revolutionized the way metal components are drilled and machined.

The Pistol Drilling Machine is a state-of-the-art piece of equipment that is designed to deliver precision drilling and machining capabilities. This advanced machine is equipped with a range of features that make it ideal for a variety of manufacturing applications, from small-scale production to large-scale industrial operations. With its high-speed drilling and cutting functions, the Pistol Drilling Machine is capable of handling a wide range of materials, including steel, aluminum, and other metals.

The innovative design of the Pistol Drilling Machine allows for greater flexibility and control during the manufacturing process. Its advanced control system enables operators to easily adjust drilling speed, depth, and other parameters, ensuring optimal precision and accuracy with every operation. This level of control is essential for producing high-quality components that meet the rigorous standards of today's manufacturing industry.

In addition to its precision drilling capabilities, the Pistol Drilling Machine also offers improved efficiency and productivity. Its automated features and advanced technology enable faster drilling and machining processes, reducing production time and enhancing overall output. This increased efficiency translates to cost savings for manufacturers, as they are able to produce more components in less time, without sacrificing quality.

Furthermore, the Pistol Drilling Machine is designed with operator safety in mind. Its robust construction and integrated safety features ensure that workers can operate the machine confidently and securely, minimizing the risk of accidents and injuries in the workplace. This focus on safety is a crucial aspect of modern manufacturing practices, and the Pistol Drilling Machine sets a new standard for equipment in this regard.

One company that has embraced the benefits of the Pistol Drilling Machine is {}. This leading manufacturer specializes in producing high-quality metal components for a diverse range of industries, including automotive, aerospace, and defense. With the integration of the Pistol Drilling Machine into their production processes, they have experienced significant improvements in efficiency, accuracy, and overall output.

The Pistol Drilling Machine has enabled {} to expand their capabilities and take on more complex projects, thanks to its advanced features and capabilities. The precision and flexibility of this cutting-edge machine have allowed {} to meet the stringent requirements of their clients, delivering components that meet or exceed industry standards.

In addition to improving their manufacturing processes, {} has also seen a notable increase in productivity and cost savings since implementing the Pistol Drilling Machine. The faster drilling and machining capabilities of the machine have reduced lead times and enhanced their ability to fulfill orders in a timely manner. This has translated to improved customer satisfaction and increased opportunities for growth and expansion.

Looking ahead, {} plans to further leverage the capabilities of the Pistol Drilling Machine to drive innovation and competitiveness in the market. With a focus on continuous improvement and investment in advanced technologies, {} aims to maintain their position as a leading provider of precision-engineered components for various industries.

The introduction of the Pistol Drilling Machine has undoubtedly had a significant impact on the manufacturing industry, offering a new level of precision, efficiency, and safety for companies looking to enhance their production capabilities. As the demand for high-quality, intricately designed components continues to grow, the Pistol Drilling Machine is poised to play a crucial role in shaping the future of manufacturing. With its advanced features and proven track record, this innovative tool is set to become a staple in modern manufacturing facilities around the world.

Company News & Blog

Professional Clipper Blade Honing Machine for Precision Sharpening - A Must-Have Tool for Groomers and Veterinarians

Clipper Blade Honing Machine Brings Precision to Grooming IndustryIn the fast-paced world of grooming and pet care, precision and efficiency are the key to success. Keeping clipper blades sharp and well-maintained is essential for maintaining high grooming standards. With this in mind, one company has developed a revolutionary Clipper Blade Honing Machine (CBHM) that is set to change the game for professionals in the grooming industry.The CBHM is the brainchild of a leading manufacturer of grooming tools and equipment. With decades of experience in the industry, the company has a deep understanding of the challenges that grooming professionals face on a daily basis. Dull clipper blades can not only compromise the quality of the grooming process but also lead to discomfort for the animals being groomed. The company recognized the need for a solution that would make blade sharpening more convenient and efficient without compromising on quality.The CBHM is a precision-engineered machine that is designed to sharpen clipper blades with unparalleled accuracy. Equipped with advanced honing technology, the machine is capable of restoring blades to their optimal cutting performance with minimal effort. It is suitable for use with a wide range of clipper blades, making it a versatile tool for grooming professionals.One of the key features of the CBHM is its user-friendly interface, which allows for easy operation by professionals of all skill levels. The machine also boasts a compact design, making it suitable for use in small grooming salons or mobile grooming units. With its high-speed honing capabilities, the CBHM can quickly restore dull blades to their original sharpness, minimizing downtime and maximizing efficiency in the grooming process.The company behind the CBHM is dedicated to providing grooming professionals with the tools they need to deliver exceptional results. In addition to the honing machine, the company offers a range of high-quality grooming equipment, including clippers, blades, and other accessories. With a commitment to innovation and quality, the company has earned a reputation as a trusted supplier to grooming professionals around the world.With the launch of the CBHM, the company aims to further solidify its position as a leading provider of grooming solutions. The machine has already garnered attention from industry professionals, who have praised its performance and ease of use. Groomers who have had the opportunity to test the machine have reported significant improvements in the sharpness and cutting performance of their blades, noting that the CBHM has become an indispensable tool in their daily operations.As the grooming industry continues to evolve, the demand for precision tools and equipment is on the rise. The introduction of the CBHM is a testament to the company's commitment to meeting the needs of grooming professionals and setting new standards for quality and efficiency in the industry. With its innovative technology and proven performance, the CBHM is poised to become a game-changer for grooming professionals seeking to elevate their standards of excellence.In conclusion, the Clipper Blade Honing Machine represents a significant advancement in grooming technology, offering a practical and effective solution for blade sharpening. With its precision engineering and user-friendly design, the machine is set to revolutionize the way grooming professionals maintain their clipper blades. As the grooming industry continues to grow, innovative tools like the CBHM will undoubtedly play a crucial role in helping professionals deliver top-notch grooming services.

Advanced and Accurate Deep Hole Drilling Machine

Precision Deep Hole Drilling Machine Revolutionizes Industrial ManufacturingIn today's fast-paced industrial manufacturing world, the demand for precision and efficiency is higher than ever. One company at the forefront of meeting this demand is (company name), a leading manufacturer of deep hole drilling machines. With a strong commitment to innovation and cutting-edge technology, (company name) has recently introduced their latest innovation – the Precision Deep Hole Drilling Machine.This state-of-the-art machine is a game-changer in the industry, offering unmatched precision and efficiency in deep hole drilling. With the ability to drill holes up to (insert maximum hole diameter) in diameter and (insert maximum hole depth) in depth, the Precision Deep Hole Drilling Machine is designed to meet the needs of the most demanding industrial applications.The secret behind the machine's superior performance lies in its advanced technology and engineering. (Company name) has leveraged their decades of experience and expertise in the field to develop a machine that pushes the boundaries of what is possible in deep hole drilling. The machine is equipped with a high-speed drill head that delivers unparalleled accuracy and consistency, while its rigid structure ensures stable and vibration-free operation.But the Precision Deep Hole Drilling Machine is more than just a powerful tool – it is also designed with the user in mind. (Company name) has incorporated intuitive controls and a user-friendly interface, making it easy for operators to set up and monitor the drilling process. In addition, the machine is equipped with advanced safety features to ensure the well-being of the operators and to minimize the risk of accidents or errors.The introduction of the Precision Deep Hole Drilling Machine has already made a significant impact in the industry. Companies across a wide range of sectors, from automotive and aerospace to oil and gas, have adopted this machine to streamline their manufacturing processes and achieve superior results. By leveraging the machine's capabilities, manufacturers are able to produce components with tighter tolerances and finer finishes, leading to improved product quality and performance.Moreover, the Precision Deep Hole Drilling Machine is also enabling manufacturers to increase their productivity and reduce lead times. Its high-speed drilling capabilities and efficient chip evacuation system allow for faster and more efficient drilling operations, ultimately leading to cost savings and improved competitiveness.(Company name) has also made it a priority to provide comprehensive support and service to their customers who have adopted the Precision Deep Hole Drilling Machine. From installation and training to ongoing maintenance and technical support, the company is committed to ensuring that their customers get the most out of this revolutionary machine.Looking ahead, (company name) is not resting on its laurels. The company continues to invest in research and development to further enhance the capabilities of the Precision Deep Hole Drilling Machine and to explore new applications for deep hole drilling technology. With a strong focus on innovation and customer satisfaction, (company name) is poised to remain a leader in the industry for years to come.In conclusion, the introduction of the Precision Deep Hole Drilling Machine represents a milestone in industrial manufacturing. With its unmatched precision, efficiency, and user-friendly design, this machine is empowering manufacturers to push the boundaries of what is possible and to achieve new levels of performance and productivity. As the industry continues to evolve, (company name) is at the forefront, driving innovation and setting new standards for deep hole drilling technology.

High Precision Horizontal Deep Hole Drilling Machine for Industrial Applications

Horizontal Deep Hole Drilling Machine Takes Precision and Efficiency to the Next LevelIn today's fast-paced manufacturing industry, companies are constantly seeking ways to improve precision and efficiency in their operations. The latest innovation to address these needs comes in the form of the Horizontal Deep Hole Drilling Machine, which is set to revolutionize the way companies approach deep hole drilling.Unlike traditional drilling machines, the Horizontal Deep Hole Drilling Machine offers a unique horizontal drilling capability that provides unparalleled precision and accessibility. This cutting-edge technology allows for deeper and more accurate drilling, making it ideal for industries such as aerospace, automotive, and mold manufacturing.One company at the forefront of this innovation is {company name}, a leading manufacturer of advanced drilling equipment. With a rich history of providing high-quality machinery to a wide range of industries, {company name} has once again raised the bar with their latest Horizontal Deep Hole Drilling Machine.{company name} has been a key player in the manufacturing industry for over 30 years, consistently delivering reliable and innovative solutions to their customers. Their commitment to research and development has resulted in the creation of cutting-edge machinery, including the Horizontal Deep Hole Drilling Machine, which is poised to set a new standard for deep hole drilling technology.The Horizontal Deep Hole Drilling Machine offers a range of features that set it apart from traditional drilling machines. Its horizontal drilling capability allows for easier access to workpieces and improved stability during the drilling process. Additionally, the machine is equipped with advanced controls and automation systems, enabling precise and efficient drilling operations.One of the key advantages of the Horizontal Deep Hole Drilling Machine is its ability to achieve deep hole drilling with unparalleled accuracy. This is essential for industries that require precise and uniform boreholes, such as the aerospace industry, where components must meet strict tolerances to ensure safety and performance.Furthermore, the machine's efficient drilling capabilities contribute to significant time and cost savings for manufacturers. By streamlining the drilling process and minimizing the need for additional finishing operations, companies can optimize their production processes and improve overall productivity.{company name} has a strong track record of delivering advanced drilling solutions to a diverse range of industries, and the Horizontal Deep Hole Drilling Machine is no exception. The company's commitment to quality, reliability, and customer satisfaction has made them a trusted partner for manufacturers seeking cutting-edge machinery.With the launch of the Horizontal Deep Hole Drilling Machine, {company name} aims to provide their customers with a game-changing solution that will revolutionize their deep hole drilling operations. By leveraging the latest technological advancements, {company name} continues to demonstrate their dedication to driving innovation and improving manufacturing processes.In conclusion, the Horizontal Deep Hole Drilling Machine represents a significant advancement in deep hole drilling technology. With its horizontal drilling capability, precision, and efficiency, this innovative machine is set to redefine the way manufacturers approach deep hole drilling. {company name}'s commitment to excellence and innovation has once again positioned them as a leader in the manufacturing industry, offering a solution that will empower companies to take their operations to the next level.

Unlocking the Secrets of Deep Hole Gundrill: Exploring the Latest Developments in High-Precision Drilling Techniques

Company X Revolutionizes Deep Hole Drilling with New Technology[City], [Date] - Company X, a leading manufacturer in the drilling industry, has recently unveiled their latest innovation - an advanced deep hole gundrill. This breakthrough technology promises to revolutionize the deep hole drilling market, providing precision and efficiency like never before.Deep hole drilling is a specialized process used in various industries such as aerospace, automotive, and oil and gas. It involves drilling holes with a high depth-to-diameter ratio, typically exceeding 10:1. Traditionally, deep hole drilling has been a laborious and time-consuming task, often prone to errors and inefficiencies.However, Company X's new deep hole gundrill is set to change the game. By combining cutting-edge technology with extensive research and development, the company has designed a drilling tool that boasts unmatched performance and accuracy.One of the key features of Company X's deep hole gundrill is its superior chip control mechanism. With the brand's patented chip-breaking technology, the drill effectively removes chips from the hole, preventing clogging and minimizing the risk of damage to the workpiece. This feature significantly enhances productivity and reduces downtime, making the entire drilling process more efficient.Furthermore, the deep hole gundrill incorporates an advanced coolant system that efficiently dissipates heat generated during drilling. This ensures optimal temperature control, thereby improving the tool's overall lifespan and sustaining high drilling performance over extended periods. The cooling system also contributes to enhanced chip evacuation, resulting in smoother drilling operations.Company X's commitment to innovation is further highlighted by the digital control technology integrated into the deep hole gundrill. The tool is equipped with intelligent sensors that monitor and adjust various drilling parameters in real-time. This allows for automated adjustments based on material properties and other factors, resulting in consistent hole quality and optimal performance.In addition to its technological prowess, Company X's new deep hole gundrill stands out in terms of durability and longevity. Constructed with high-quality materials and advanced coatings, the drill offers remarkable resistance to wear, corrosion, and mechanical stresses. This ensures a prolonged lifespan, reducing the need for frequent replacements and ultimately saving costs for end-users.With their latest innovation, Company X aims to address the industry's growing need for more efficient deep hole drilling solutions. By streamlining the drilling process and enhancing performance, this advanced tool is expected to boost productivity and elevate the overall quality of deep hole drilling operations across various sectors.In line with their commitment to customer satisfaction, Company X also provides comprehensive technical support and after-sales service. Their team of highly skilled engineers and technicians is readily available to assist customers with installation, maintenance, and troubleshooting, ensuring a seamless user experience and maximum uptime.Company X's new deep hole gundrill has already been well-received in several pilot projects and has gained significant attention from industry experts. Its successful integration into operations has demonstrated remarkable improvements in productivity, precision, and cost-effectiveness.As the drilling industry continues to evolve, Company X remains at the forefront of innovation, constantly pushing boundaries and redefining industry standards. With their latest deep hole gundrill, the company is set to make a lasting impact, providing customers with a cutting-edge solution for their deep hole drilling needs.

High-Quality Engine Honing Machine for Precise Machining Results

For immediate release:The demand for high precision and efficient engine honing machines is rapidly increasing in the automotive industry. In order to meet this demand, {Company Name} is proud to announce the launch of their latest engine honing machine that is set to revolutionize the industry.With over 20 years of experience in manufacturing precision machinery, {Company Name} has built a solid reputation for delivering high-quality products that meet the evolving needs of their customers. The new engine honing machine is no exception, as it is specifically designed to provide superior performance and accuracy in honing engine cylinders.The key features of this cutting-edge machine include advanced honing technology, a user-friendly interface, and the ability to hone a wide range of engine cylinders with unparalleled precision. The machine is also equipped with state-of-the-art automation and control systems, allowing for efficient and consistent honing results.In addition to its advanced features, the engine honing machine is also designed with the needs of the operator in mind. It is built for ease of use, with intuitive controls and a compact design that maximizes space on the factory floor. This ensures that operators can work efficiently and safely, leading to increased productivity and reduced downtime.Furthermore, {Company Name} prides itself on delivering exceptional customer support and service. Their team of experienced engineers and technicians are dedicated to providing comprehensive training, maintenance, and technical assistance to ensure that customers get the most out of their investment in the engine honing machine.In response to the launch of the new engine honing machine, the CEO of {Company Name} expressed their enthusiasm and confidence in the product. "We are thrilled to introduce this cutting-edge engine honing machine to the market. It is a testament to our commitment to innovation and excellence, and we are confident that it will set a new standard for precision and performance in engine honing."The new engine honing machine from {Company Name} is set to make a significant impact in the automotive industry. Its advanced technology and user-friendly design are expected to streamline the engine honing process, leading to improved efficiency and quality in engine manufacturing.As the automotive industry continues to evolve, {Company Name} remains at the forefront of innovation, delivering solutions that empower their customers to stay competitive in the market. The launch of this new engine honing machine is a testament to their ongoing dedication to providing the highest quality machinery for the modern automotive manufacturing industry.For more information about the new engine honing machine and other products from {Company Name}, please visit their website or contact them directly for inquiries and demonstrations.Contact Information:{Company Name}Address: [Insert Address]Phone: [Insert Phone Number]Email: [Insert Email Address]Website: [Insert Website URL]

High-Performance Drilling Machine for Gun Barrels Available Now

Gun Barrel Drilling Machine Revolutionizes Firearms ManufacturingGun manufacturing has undergone a revolutionary transformation with the introduction of the latest state-of-the-art Gun Barrel Drilling Machine by a leading industrial machinery company. The cutting-edge technology of this innovative machine has set a new standard in precision and efficiency for the production of firearm barrels.The Gun Barrel Drilling Machine, developed by the company's team of expert engineers and designers, has revolutionized the way in which gun barrels are manufactured. This advanced machine is capable of drilling precise and uniform bores in a wide range of firearm barrels, ensuring exceptional accuracy and consistency in the production process.The company's commitment to continuous innovation and improvement is evident in the development of this groundbreaking Gun Barrel Drilling Machine. With its advanced features and unparalleled precision, this machine has significantly enhanced the quality and performance of firearm barrels, setting a new benchmark for the industry.One of the key features of the Gun Barrel Drilling Machine is its ability to drill and ream barrels with utmost precision, resulting in superior bore quality and alignment. This level of accuracy is crucial in ensuring that each firearm barrel meets the highest standards for performance and reliability.Furthermore, the machine's advanced automation and control systems enable it to operate with exceptional speed and efficiency, significantly reducing the production time for firearm barrels. This not only improves the overall productivity of firearm manufacturing but also allows for a more streamlined and cost-effective production process.In addition to its remarkable precision and efficiency, the Gun Barrel Drilling Machine is also designed with versatility in mind. It is capable of drilling a wide range of barrel sizes and configurations, making it suitable for the production of various types of firearms, including rifles, shotguns, and handguns.The company's dedication to excellence and innovation has earned it a reputation as a leader in the industrial machinery industry. With a strong focus on research and development, the company continues to push the boundaries of technology to deliver cutting-edge solutions that meet the evolving needs of its customers.The introduction of the Gun Barrel Drilling Machine is a testament to the company's commitment to providing the firearms industry with innovative and game-changing manufacturing solutions. By leveraging the latest advancements in engineering and automation, the company has undoubtedly set a new standard for precision and efficiency in firearm barrel production.The company's success in developing the Gun Barrel Drilling Machine is a result of its relentless pursuit of excellence and its unwavering dedication to exceeding customer expectations. With a proven track record of delivering high-quality industrial machinery, the company has firmly established itself as a trusted partner for manufacturers in the firearms industry.In conclusion, the introduction of the Gun Barrel Drilling Machine marks a significant milestone in the evolution of firearm manufacturing. With its unprecedented precision, efficiency, and versatility, this cutting-edge machine has set a new benchmark for the production of firearm barrels, solidifying the company's position as a leader in the industrial machinery industry. As the firearms industry continues to evolve, the company remains at the forefront, driving innovation and delivering solutions that empower manufacturers to achieve new levels of quality and performance.

High-Quality Vertical Cylinder Honing Machine for Precision Machining

Vertical Cylinder Honing Machine Revolutionizes Precision MachiningIn today's fast-paced manufacturing industry, precision and efficiency are key factors in ensuring the quality of the final products. With the introduction of the Vertical Cylinder Honing Machine (VCHM), companies are now able to achieve a new level of precision in honing cylinders, revolutionizing the way they approach precision machining.The VCHM, developed by a leading manufacturer in the machining industry, has set a new standard for precision machining. Through its innovative design and advanced technology, the VCHM has changed the game for manufacturers who require precise cylinder honing for their products.The VCHM is equipped with state-of-the-art features that allow for a high level of precision and accuracy in cylinder honing. Its vertical design provides enhanced stability and rigidity, ensuring that the honing process is carried out with utmost precision. Additionally, the machine is equipped with a sophisticated control system that allows for precise adjustments and monitoring of the honing process, resulting in a superior finish on the cylinders.One of the key advantages of the VCHM is its ability to hone cylinders of various sizes and materials with consistently high precision. This versatility allows manufacturers to streamline their honing processes and achieve uniform results across different products. Whether it is aluminum, cast iron, or steel cylinders, the VCHM is capable of producing impeccable finishes, meeting the exact specifications of the product designs.Furthermore, the VCHM is designed with efficiency in mind, allowing manufacturers to optimize their production processes. Its automated features and intuitive control system enable operators to carry out honing operations with minimal effort and time, leading to increased productivity and cost savings. The VCHM's ability to deliver consistently high-quality results in a shorter timeframe gives manufacturers a competitive edge in the industry.The company behind the development of the VCHM, with over 30 years of experience in the machining industry, has a strong track record of delivering cutting-edge solutions that meet the evolving needs of manufacturers. By combining advanced engineering expertise with a deep understanding of industry requirements, the company has positioned itself as a leader in providing innovative machining solutions.With a commitment to continuous improvement and innovation, the company has invested heavily in research and development to bring the VCHM to market. Its dedication to pushing the boundaries of precision machining has resulted in the creation of a game-changing product that has redefined the standards for cylinder honing.In addition to its technological prowess, the company also prioritizes customer satisfaction, offering comprehensive support and service to ensure that manufacturers can maximize the benefits of the VCHM. From installation and training to ongoing maintenance and technical assistance, the company stands by its product, providing customers with the confidence to integrate the VCHM into their operations seamlessly.The introduction of the Vertical Cylinder Honing Machine marks a significant advancement in the field of precision machining, offering manufacturers a powerful tool to elevate the quality and efficiency of their production processes. With its innovative design, advanced technology, and unwavering commitment to customer satisfaction, the VCHM has set a new standard for cylinder honing, solidifying its position as a game-changer in the industry.As manufacturing continues to evolve, the Vertical Cylinder Honing Machine stands as a testament to the potential of innovation in driving progress and raising the bar for precision machining. It is a testament to the power of technological innovation in transforming the way we approach manufacturing processes, and a beacon of hope for the future of the industry.

Advanced Automatic Honing Machine for Precision Engine Honing

The CNC Automatic Honing Machine is a revolutionary piece of equipment in the manufacturing industry, providing precision and efficiency in the honing process. Using advanced technology and automated processes, this honing machine is able to produce high-quality results with minimal human intervention. This innovative piece of machinery is changing the way companies approach honing, making the process faster, more accurate, and more cost-effective.With the rise of Industry 4.0 and the increasing demand for precision-engineered products, the need for advanced honing machines has never been greater. This is where the CNC Automatic Honing Machine comes in, offering a solution that meets the needs of modern manufacturing. By automating the honing process, this machine reduces the risk of human error and ensures consistent results every time. This level of precision and reliability is essential for industries such as automotive, aerospace, and hydraulic systems, where quality is of the utmost importance.The CNC Automatic Honing Machine is equipped with state-of-the-art technology that allows for highly accurate and efficient honing. With its computer numerical control (CNC) capabilities, the machine can be programmed to perform a wide range of honing tasks with incredible precision. This level of automation not only saves time and labor costs but also improves the overall quality of the finished products.In addition to its advanced technology, the CNC Automatic Honing Machine also boasts a user-friendly interface, making it easy to operate and maintain. This means that even companies with limited experience in honing can benefit from this machine, as it requires minimal training and expertise to use effectively. As a result, manufacturers can achieve higher levels of productivity and efficiency without the need for extensive retooling or retraining.The company behind the CNC Automatic Honing Machine, {Company Name}, has a proven track record of delivering innovative and reliable manufacturing solutions. With years of experience in the industry, the company has become a trusted name in the field of precision machining equipment. Their commitment to excellence and customer satisfaction is evident in the quality of their products, and the CNC Automatic Honing Machine is no exception.{Company Name} takes pride in offering cutting-edge solutions that help their clients stay ahead of the curve in a constantly evolving industry. The CNC Automatic Honing Machine is the latest example of their dedication to providing state-of-the-art technology that meets the needs of modern manufacturing. By combining their expertise in precision engineering with the latest advancements in automation, {Company Name} has created a honing machine that sets a new standard for quality and efficiency.The CNC Automatic Honing Machine is a game-changer for manufacturers looking to streamline their honing processes and improve the quality of their products. Its advanced technology, user-friendly interface, and proven reliability make it an invaluable asset for any company looking to stay competitive in today's challenging market. With the backing of {Company Name}'s reputation for excellence, this honing machine is set to become an essential tool for the manufacturing industry.In conclusion, the CNC Automatic Honing Machine represents a significant advancement in the field of precision machining equipment. Its advanced technology and automated processes make it a game-changer for manufacturers looking to improve the quality and efficiency of their honing processes. With {Company Name} behind it, this honing machine is set to become an essential tool for companies looking to stay ahead of the competition in a rapidly evolving industry.

High-Precision Electric Honing Machine for Precision Machining

Electric Honing Machine Revolutionizes the Industry with Innovative Technology[Company Name] is proud to introduce the latest addition to their line of cutting-edge machining tools: the Electric Honing Machine. This state-of-the-art machine is set to revolutionize the honing industry with its advanced technology and incredible precision. With this new addition, [Company Name] aims to set new standards for honing processes and to provide their customers with the most efficient and accurate machining solutions.The Electric Honing Machine is designed to meet the growing demands of modern machining processes. It is equipped with cutting-edge technology that allows for precise control and enhanced performance. This machine offers a wide range of capabilities, including honing, polishing, and finishing, making it an ideal choice for a variety of industries, from automotive to aerospace.One of the key features of the Electric Honing Machine is its advanced control system, which enables operators to adjust parameters such as speed, pressure, and stroke length with unparalleled accuracy. This level of control ensures that the machine can achieve the exact specifications required for each individual project, leading to consistent and high-quality results.In addition to its precise control system, the Electric Honing Machine also boasts a robust and durable construction. The machine is built to withstand the rigors of heavy-duty industrial use, ensuring reliable performance and longevity. Its design allows for easy maintenance and servicing, reducing downtime and increasing productivity for a wide range of applications.The Electric Honing Machine is also equipped with a range of safety features to protect both operators and the machine itself. These features include automatic shut-off mechanisms, emergency stop buttons, and protective enclosures, ensuring a safe working environment for all operators.Furthermore, [Company Name] prides itself on providing exceptional customer support and service. They offer comprehensive training programs for operators, along with 24/7 technical support to address any issues or concerns that may arise. This commitment to customer satisfaction sets [Company Name] apart as a leader in the machining industry.With the introduction of the Electric Honing Machine, [Company Name] continues to demonstrate their dedication to innovation and excellence. This new addition to their product line is poised to have a significant impact on the honing industry, offering a level of precision and performance that is unmatched by other machines in the market.In conclusion, the Electric Honing Machine from [Company Name] represents a significant leap forward in the honing industry. With its advanced technology, precise control, and robust construction, this machine sets new standards for machining processes. Customers can expect unparalleled performance and reliability, backed by exceptional customer support and service. As [Company Name] looks towards the future, they remain committed to providing cutting-edge solutions for their customers' machining needs.

Discover the Benefits of Vertical Cylinder Honing Machines for Effective Precision Honing

Vertical Cylinder Honing Machine Enhances Efficiency and Precision in Engine ManufacturingIn the competitive landscape of engine manufacturing, companies are constantly seeking ways to enhance their efficiency and precision. One company has risen to the challenge with its latest innovation - the Vertical Cylinder Honing Machine. Designed to remove the brand name's top-of-the-line features, this cutting-edge technology is revolutionizing the engine manufacturing industry.With precision being the key in engine manufacturing, honing the cylinders is a critical process that ensures optimal engine performance. The Vertical Cylinder Honing Machine takes this process to a whole new level, offering enhanced accuracy and efficiency. By removing imperfections on the surface of the cylinder walls, the machine ensures a smooth finish, allowing the piston rings to perform at their best.One of the standout features of this machine is its vertical setup, which offers several advantages over traditional horizontal honing machines. The vertical orientation allows for better control and stability during the honing process, resulting in improved accuracy and a superior surface finish. This unique design also reduces the risk of damage to the cylinder walls, minimizing scrap rates and optimizing productivity.The Vertical Cylinder Honing Machine is equipped with advanced technologies that further enhance its performance. A precise servo motor-controlled spindle enables precise speed and feed rate adjustments, ensuring consistent and uniform honing across all cylinders. In addition, the machine is equipped with an automatic tool compensation system that adjusts the honing stones' position based on performance feedback, ensuring optimal results and reducing operator error.The company behind this groundbreaking technology has been a frontrunner in the engine manufacturing industry for several decades. With a strong commitment to innovation, quality, and customer satisfaction, they have earned a stellar reputation worldwide. Their extensive experience in developing cutting-edge machinery has positioned them as a trusted partner for companies across the industry.The introduction of the Vertical Cylinder Honing Machine further solidifies their position as a leader in engine manufacturing technology. By addressing the challenges faced in the honing process, this machine effectively improves productivity and output quality. The company's dedication to research and development is evident in its relentless pursuit of excellence, resulting in the creation of this game-changing technology.Customer testimonials validate the success of this revolutionary machine. Engine manufacturers who have incorporated the Vertical Cylinder Honing Machine into their production process have reported significant improvements in efficiency and precision. The ability to deliver engines with superior performance and reduced scrap rates has led to increased customer satisfaction and competitiveness in the market.The use of advanced technology and precision engineering has always been a cornerstone of this company's philosophy. As engine technology continues to evolve, the company remains committed to developing innovative solutions that meet the ever-increasing demands of the industry. With the Vertical Cylinder Honing Machine, they have once again proven their ability to push the boundaries of what is possible in engine manufacturing.In conclusion, the Vertical Cylinder Honing Machine is a game-changer in the engine manufacturing industry. Combining advanced technology, precision engineering, and a vertical setup, this machine offers enhanced efficiency and accuracy in the honing process. With its introduction, the company behind this innovation reaffirms its position as a leader in engine manufacturing technology and continues to push the boundaries of excellence in the industry.