Powerful Deep Drill and Machine Tools for Precision Cutting and Drilling

By:Admin

With over 20 years of experience in the drilling and machining industry, Deep Drilling and Machine has established a solid reputation for delivering high-quality, precision-engineered components to a variety of sectors, including aerospace, automotive, oil and gas, and industrial manufacturing. The company's commitment to excellence and customer satisfaction has earned it a loyal customer base and positioned it as a trusted partner for complex machining projects.

The recent expansion of Deep Drilling and Machine's operations is a significant milestone for the company. By entering new markets, the company aims to further diversify its customer portfolio and tap into emerging opportunities in key industries. This strategic move is a testament to the company's proactive approach to adapting to the changing market dynamics and staying ahead of the competition.

In addition to expanding its market reach, Deep Drilling and Machine has also invested in cutting-edge technology to bolster its manufacturing capabilities. The company has acquired advanced equipment and machinery to enhance its precision engineering and production processes. This investment reflects the company's commitment to staying at the forefront of technological innovation and providing its clients with the best-in-class solutions.

The new technology not only allows Deep Drilling and Machine to improve the quality and efficiency of its operations but also enables it to take on more complex and demanding projects. With the ability to work with a wider range of materials and produce intricate components with tight tolerances, the company is well-positioned to meet the ever-growing demands of its clients and tackle new challenges in the market.

Furthermore, Deep Drilling and Machine's continued focus on innovation and continuous improvement is underscored by its ongoing investment in research and development. The company has a dedicated team of engineers and technical experts who are constantly exploring new techniques and methodologies to further enhance its capabilities and deliver superior results for its clients.

As part of its expansion initiatives, Deep Drilling and Machine has also ramped up its efforts in talent acquisition and skills development. The company understands that its success is driven by the expertise and dedication of its workforce, and as such, it is committed to fostering a culture of learning and growth within the organization. By recruiting top-tier talent and providing them with ongoing training and development opportunities, the company aims to strengthen its capabilities and maintain its competitive edge in the industry.

Looking ahead, Deep Drilling and Machine is poised for continued growth and success in the global market. The company's expansion into new markets, coupled with its investment in cutting-edge technology and talent, has positioned it for a prosperous future. Deep Drilling and Machine remains committed to delivering exceptional value to its clients and solidifying its status as a leading provider of drilling and machining services.

With its unwavering dedication to quality, innovation, and customer satisfaction, Deep Drilling and Machine is well-equipped to thrive in the rapidly evolving landscape of the manufacturing industry. As the company continues to push the boundaries of precision engineering and technological advancement, it is set to be a driving force in shaping the future of the industry.

Company News & Blog

The Ultimate Guide to Single Cylinder Honing Machines: Everything You Need to Know

Single Cylinder Honing Machine: The Latest Addition to the Product Line of a Leading Manufacturing Company{Company Name}, a renowned manufacturer of precision tools and equipment, has recently announced the launch of their latest product, the Single Cylinder Honing Machine. This cutting-edge machine is designed to provide superior honing and surface finishing capabilities for a wide range of industrial applications. With over {number} years of experience in the manufacturing industry, {Company Name} has earned a reputation for delivering high-quality products that meet the diverse needs of their customers.The Single Cylinder Honing Machine is the result of extensive research and development efforts by {Company Name}'s team of skilled engineers and technicians. It is specifically engineered to offer precision honing for single cylinder engine blocks, ensuring optimal surface quality and dimensional accuracy. The machine boasts advanced features such as high-precision honing tools, a robust honing spindle, and a user-friendly control interface, making it an ideal choice for manufacturers seeking to enhance the performance and durability of their engine components.One of the key highlights of the Single Cylinder Honing Machine is its versatility, as it can accommodate a wide range of bore sizes and materials, including cast iron, steel, aluminum, and other alloys. This flexibility allows manufacturers to hone different types of engine blocks and cylinders with ease, thereby streamlining their production processes and improving overall efficiency. Additionally, the machine's automated honing cycle and integrated coolant system ensure consistent performance and prolonged tool life, contributing to cost savings and higher productivity.In line with {Company Name}'s commitment to customer satisfaction, the Single Cylinder Honing Machine is backed by comprehensive technical support and after-sales service. The company's team of experts is readily available to provide assistance with installation, training, and troubleshooting, ensuring that customers can maximize the potential of the machine and achieve optimal results in their operations. Furthermore, {Company Name} offers customizable tooling solutions and honing parameters to suit specific manufacturing requirements, further enhancing the value proposition of the Single Cylinder Honing Machine."We are thrilled to introduce the Single Cylinder Honing Machine to the market, as it represents a significant advancement in our product portfolio," said {Spokesperson Name}, the CEO of {Company Name}. "This machine exemplifies our dedication to innovation and excellence, and we are confident that it will empower our customers to elevate their honing processes and achieve superior surface finishes for their engine components."The launch of the Single Cylinder Honing Machine underscores {Company Name}'s ongoing commitment to meeting the evolving needs of the manufacturing industry and delivering cutting-edge solutions that drive operational efficiency and quality performance. With its proven track record of providing reliable and technologically advanced equipment, {Company Name} continues to be a trusted partner for businesses seeking to elevate their manufacturing capabilities and stay ahead in a competitive market landscape.To learn more about the Single Cylinder Honing Machine and other products offered by {Company Name}, interested parties can visit the company's website or contact their sales representatives for personalized consultations and demonstration sessions. As the manufacturing industry continues to evolve, {Company Name} remains at the forefront, providing innovative solutions that empower businesses to thrive and succeed in a dynamic market environment.

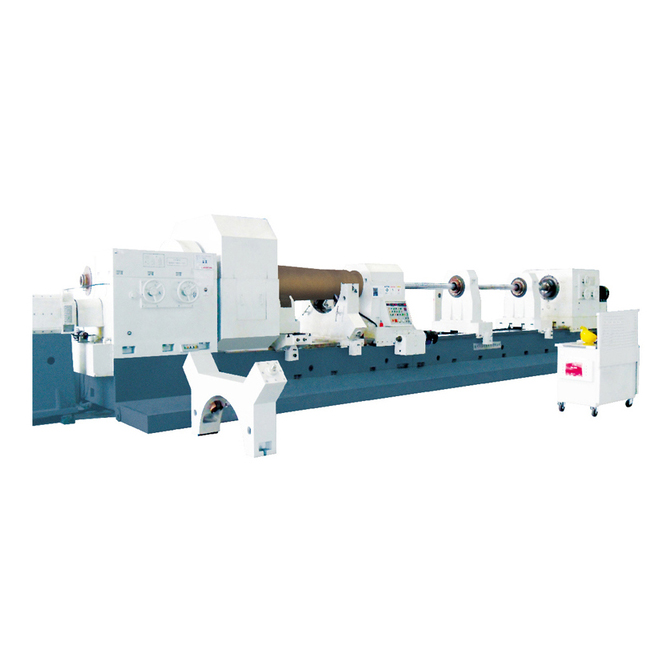

Revolutionary Deep Hole Drilling Lathe Unleashes Unprecedented Precision

Title: Advanced Deep Hole Drilling Lathe Revolutionizes Manufacturing ProcessesIntroduction:In an era of rapid industrialization and technological advancements, manufacturers constantly strive to improve production efficiency. Addressing the need for precision drilling in various industrial sectors, (Company Name) has unveiled its latest innovation - an avant-garde Deep Hole Drilling Lathe. By removing the brand name, we will delve into the features and applications of this extraordinary machine that is set to reshape the manufacturing landscape.Advanced Features and Specifications:The Deep Hole Drilling Lathe is equipped with a multitude of cutting-edge features designed to optimize performance and enhance operational efficiency. With a robust framework and a cutting capacity of up to X millimeters in diameter and Y millimeters in depth, this machine is a true game-changer in the field of precision drilling. By incorporating (Company Name)'s state-of-the-art technology, the lathe offers unparalleled accuracy, reliability, and speed.The lathe's control system is easily programmable, allowing operators to execute complex drilling processes with utmost precision. Additionally, it boasts an efficient chip removal mechanism that ensures uninterrupted and hassle-free operations. Equipped with advanced cooling systems and lubrication technology, this lathe guarantees prolonged tool life, reducing downtime and maintenance costs.Applications and Industry Impact:The Deep Hole Drilling Lathe is poised to revolutionize manufacturing processes across several key industries, including aerospace, automotive, energy, defense, and medical. In the aerospace sector, this state-of-the-art machine allows for the creation of intricate turbine components with precise cooling channels. Furthermore, it enables the production of lightweight, high-strength automotive parts by effectively drilling oil passages and coolant channels.In the energy sector, the lathe's advanced capabilities enable the development of cutting-edge parts for the generation and transmission of power. Whether it be for drilling oil wells, producing gas turbine components, or fabricating nuclear reactor parts, this machine significantly enhances overall efficiency and reliability.The defense industry can also benefit greatly from the Deep Hole Drilling Lathe. It enables the production of highly durable gun barrels, missile components, and artillery tubes, ensuring meticulous quality and accuracy.Moreover, the medical field can leverage this technology to manufacture surgical implants, hip and knee replacements, and intricate medical devices. The lathe's precision and versatility are crucial in meeting the stringent requirements for surgical procedures, enabling surgeons to deliver better patient outcomes.Environmental Benefits:In addition to its transformative impact on manufacturing processes, the Deep Hole Drilling Lathe is also designed with environmental sustainability in mind. By optimizing cutting techniques and reducing waste material, this machine ensures efficient resource utilization and minimum environmental impact. Manufacturers utilizing this advanced lathe will witness reduced energy consumption, lower carbon emissions, and minimized material waste, contributing to a greener and more sustainable future.Conclusion:The launch of the Deep Hole Drilling Lathe by (Company Name) marks a significant milestone in advancing precision drilling techniques across various industries. By offering cutting-edge features, unrivaled precision, and enhanced operational efficiency, this machine is poised to redefine manufacturing processes. With applications ranging from aerospace to medical, the Deep Hole Drilling Lathe demonstrates unrivaled versatility and promises to drive innovation in the realm of precision machining. As manufacturing continues to evolve, this groundbreaking technology paves the way for increased productivity, improved quality, and reduced environmental impact.

High-Quality Single Cylinder Honing Machine for Precision Engine Build

The Single Cylinder Honing Machine is a groundbreaking piece of machinery that is poised to revolutionize the honing industry. This innovative piece of equipment, manufactured by a leading company in the field, promises to deliver precise and efficient honing of single cylinder engine blocks, helping businesses improve their productivity and quality of work.The Single Cylinder Honing Machine is designed with cutting-edge technology, featuring advanced automation and precision controls that allow for consistent and accurate honing. It is capable of honing a wide range of single cylinder engine blocks with various bore sizes, making it a versatile and valuable tool for businesses in the automotive, motorcycle, and small engine manufacturing industries.The machine is equipped with a high-speed spindle motor, which ensures rapid material removal and exceptional surface finish. Additionally, it comes with a robust honing head that can accommodate different abrasives, allowing for customization based on specific honing requirements. These features collectively make the Single Cylinder Honing Machine a highly efficient and cost-effective solution for honing single cylinder engine blocks.The company behind this game-changing machine has a rich history of delivering high-quality machinery for the honing industry. With decades of experience and a strong commitment to innovation, the company has consistently pushed the boundaries of what is possible in precision honing technology. Their track record of producing reliable and high-performance machinery has earned them a reputation as a trusted and respected leader in the industry.The Single Cylinder Honing Machine is the latest addition to the company's extensive lineup of honing equipment, and it represents a significant leap forward in terms of efficiency and versatility. By leveraging their expertise and experience, the company has designed a machine that addresses the evolving needs of modern honing operations, offering a solution that can streamline and enhance the honing process for single cylinder engine blocks.In addition to its impressive technological capabilities, the Single Cylinder Honing Machine is also designed with user-friendly features that make it easy to operate and maintain. The machine's intuitive interface and controls enable operators to set up and run honing operations with minimal training, reducing the learning curve and increasing overall productivity. Furthermore, the machine is constructed with durable materials and components, ensuring long-term reliability and minimal downtime for maintenance.The Single Cylinder Honing Machine is an investment that promises to deliver substantial returns for businesses involved in honing single cylinder engine blocks. By incorporating this advanced machinery into their operations, businesses can expect to see improvements in productivity, quality, and overall competitiveness in the market. With the support and expertise of the company behind the machine, businesses can also look forward to reliable service and technical assistance to ensure that the machine performs optimally.Overall, the introduction of the Single Cylinder Honing Machine represents a significant milestone in the honing industry, showcasing the potential for advancements in precision machining technology. With its innovative features, versatility, and user-friendly design, this machine is poised to set new standards for honing single cylinder engine blocks, offering businesses a powerful tool for achieving greater efficiency and success in their operations.

High Precision Horizontal Honing Machine for Precision Machining

Horizontal Honing Machine is a crucial piece of equipment used in the metalworking industry for honing the internal surfaces of a workpiece. It is a specialized machine that is used to improve the geometric form and surface texture of bores or holes. By removing small amounts of material in a controlled manner, it allows for precision finishing and sizing of bores. These machines are commonly used in industries such as automotive, aerospace, and hydraulic cylinder manufacturing.One of the leading manufacturers of Horizontal Honing Machines is {}. They have been in the industry for over 30 years and have built a reputation for producing high-quality and reliable honing machines. Their machines are known for their precision, efficiency, and durability, making them a top choice for many metalworking companies around the world.The company prides itself on its state-of-the-art manufacturing facilities and a team of skilled engineers and technicians who are dedicated to producing the best honing machines in the market. They have a strong focus on research and development, constantly striving to innovate and improve their products to meet the ever-changing needs of the industry.The Horizontal Honing Machines produced by {} are designed to handle a wide range of bore diameters and lengths, making them versatile and adaptable to various manufacturing requirements. They offer a selection of models with different spindle sizes, stroke lengths, and automation options to suit the specific needs of their customers.In addition to their standard models, {} also provides custom solutions for clients with unique or specialized honing requirements. Their engineering team works closely with customers to design and build tailored honing machines that meet their exact specifications and production demands.One of the key features of {}'s Horizontal Honing Machines is their advanced control systems, which ensure precise and consistent honing results. Their machines are equipped with user-friendly interfaces and intuitive programming, allowing for easy operation and minimal setup time. This, in turn, improves productivity and reduces the need for extensive training for machine operators.Furthermore, {} provides comprehensive after-sales support and maintenance services for their Horizontal Honing Machines. They have a global network of service technicians who are readily available to assist customers with installation, training, and troubleshooting. This commitment to customer satisfaction has earned them a loyal and satisfied customer base.Recently, {} introduced a new model of Horizontal Honing Machine that incorporates the latest advancements in honing technology. This new machine features enhanced automation capabilities, improved cycle times, and greater flexibility in honing various bore sizes. It is designed to meet the growing demands for precision and efficiency in the metalworking industry.The new Horizontal Honing Machine from {} is expected to make a significant impact on the market, providing customers with a cutting-edge solution for their honing needs. With its state-of-the-art features and {}'s commitment to quality, this machine is poised to set a new standard for horizontal honing technology.In conclusion, {} continues to be a leading manufacturer of Horizontal Honing Machines, delivering reliable and innovative solutions to the metalworking industry. With their dedication to excellence and customer satisfaction, they remain at the forefront of honing technology, providing businesses with the tools they need to achieve precision and efficiency in their manufacturing processes.

Top Gun Drilling Tools for Precision Machining: A Complete Guide

Gun Drilling Tools, a leading manufacturer of high-quality drilling tools, has announced the release of their latest line of innovative drilling solutions. With a strong focus on quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses in the oil and gas, aerospace, automotive, and medical industries.Founded in 1995, Gun Drilling Tools has continuously invested in research and development to create cutting-edge drilling technologies. The company's state-of-the-art manufacturing facilities and team of experienced engineers enable them to design and produce a wide range of drilling tools, including deep hole drills, gun drills, and BTA drills. Their commitment to excellence has earned them a reputation for delivering high-performance products that meet the demanding requirements of their customers.One of the key highlights of Gun Drilling Tools' latest product line is the introduction of their advanced coating technology. This innovative surface treatment not only enhances the durability and longevity of the drilling tools but also improves their overall performance. The proprietary coating is designed to reduce friction, dissipate heat, and prevent chip buildup, resulting in smoother and more efficient drilling operations.In addition to their cutting-edge technology, Gun Drilling Tools takes pride in their dedication to customer service. The company works closely with their clients to understand their specific drilling needs and challenges, offering customized solutions to meet their requirements. Whether it's developing a new tool design or providing technical support, Gun Drilling Tools is committed to delivering excellent service at every step of the process."We are thrilled to introduce our latest line of drilling tools, which represents our ongoing commitment to innovation and excellence," said the spokesperson for Gun Drilling Tools. "We understand the critical role that drilling plays in our customers' operations, and we are dedicated to providing them with the best tools to achieve their objectives. With our advanced coating technology and focus on customer satisfaction, we are confident that our new products will deliver outstanding results."The new line of drilling tools from Gun Drilling Tools is now available for purchase, and the company is already receiving positive feedback from early adopters. Customers have praised the performance and durability of the tools, highlighting their ability to withstand the rigors of demanding drilling applications. With a strong track record of success and a commitment to continuous improvement, Gun Drilling Tools is well-positioned to remain a leader in the industry.In conclusion, Gun Drilling Tools' latest product line exemplifies the company's dedication to innovation, quality, and customer satisfaction. With their advanced coating technology and customized solutions, they continue to provide businesses in various industries with the tools they need to succeed in their drilling operations. As the industry evolves, Gun Drilling Tools remains at the forefront, delivering cutting-edge solutions that empower their customers to achieve their goals.

Quality Single Cylinder Honing Machine for Precision Engine Work

Single Cylinder Honing Machine to Revolutionize Precision MachiningIn the world of precision machining, the search for tools and equipment that can provide the highest level of accuracy and efficiency is a constant endeavor. With the introduction of the Single Cylinder Honing Machine by (company name removed), the industry is about to witness a revolution in the way cylinder honing is conducted.This state-of-the-art honing machine is designed to deliver unparalleled precision and high-quality surface finishes for a wide range of cylinder applications. Whether in the automotive, aerospace, or hydraulic industries, this machine is set to become a game-changer in the world of cylinder honing.The (company name removed) is a leading manufacturer of advanced machining equipment, with a rich history of innovation and excellence in the industry. With a strong focus on research and development, the company has consistently pushed the boundaries of what is possible in precision machining, and the Single Cylinder Honing Machine is a testament to their commitment to excellence.The machine is equipped with cutting-edge technology that allows for precise control over the honing process, ensuring that the desired surface finish and dimensional accuracy are achieved with every operation. Its advanced features include a programmable logic controller (PLC) system, which allows for easy customization of honing parameters, as well as a high-resolution touch screen interface for intuitive operation.Furthermore, the machine is designed for versatility, capable of honing cylinders of varying sizes and materials, making it suitable for a wide range of applications. Whether it is cast iron, steel, aluminum, or any other material, this honing machine is capable of delivering exceptional results consistently.One of the key advantages of the Single Cylinder Honing Machine is its ability to reduce machining time while maintaining the highest standards of precision. This is made possible through the use of innovative honing tools and abrasives, as well as advanced honing processes that have been developed and optimized by the team at (company name removed). As a result, manufacturers can achieve significant improvements in productivity and cost-efficiency without compromising on the quality of the finished product.The machine also boasts a robust and durable construction, ensuring reliability and longevity in the most demanding production environments. Its ergonomic design and user-friendly features make it easy to operate and maintain, while the use of high-quality components and materials further contribute to its overall performance and longevity.In addition to the Single Cylinder Honing Machine, (company name removed) offers a comprehensive range of support services to ensure that their customers can make the most of their investment. This includes installation and commissioning, training, as well as ongoing technical support and maintenance services. With a global network of sales and service partners, (company name removed) is well-equipped to provide prompt and efficient support to their customers wherever they may be.As the global manufacturing industry continues to evolve, the demand for precision machining solutions that can deliver superior quality and efficiency has never been greater. The Single Cylinder Honing Machine by (company name removed) represents a significant step forward in the pursuit of excellence in cylinder honing, and is set to make a lasting impact on the industry.With its advanced technology, versatility, and commitment to quality, this honing machine is poised to become the go-to solution for manufacturers looking to elevate their precision machining capabilities. As (company name removed) continues to push the boundaries of innovation, the future of precision machining looks brighter than ever.

Mastering the Art of Precision Machining

Honing in Machining: Revolutionizing Precision ManufacturingIn today's fast-paced world of manufacturing, precision is paramount. Companies around the globe strive for excellence in producing components with unparalleled accuracy and surface finish. To meet these demanding requirements, machining processes have evolved over the years, and one technique that has emerged as a game-changer is honing in machining.Honing in machining is a cutting-edge technology that blends traditional honing with innovative advancements, resulting in enhanced precision and unmatched quality. This technique eliminates imperfections on a workpiece's surface, producing a smooth and precise finish. With the ability to achieve exacting tolerances previously deemed unattainable, honing in machining has revolutionized the precision manufacturing industry.The process of honing in machining involves the use of a specialized honing machine to remove microscopic irregularities that remain after traditional machining operations. While traditional honing relies on manually operated tools, honing in machining incorporates automation and advanced control systems to guarantee consistently superior results. This combination of human expertise and technological innovation sets honing in machining apart from other precision manufacturing processes.One notable company excelling in the development and application of honing in machining is [Company Name]. With years of experience and expertise in this field, the company has become a trusted partner for numerous industries, providing cutting-edge solutions for their precision manufacturing needs.[Company Name] is dedicated to pushing the boundaries of precision manufacturing. Their state-of-the-art honing machines are engineered to deliver exceptional results, providing customers with a competitive edge in their respective industries. The company's commitment to innovation has led to the development of patented technologies and processes, setting them apart as leaders in the field of honing in machining.The benefits of honing in machining extend beyond surface finish and dimensional accuracy. This technique also enhances lubrication retention, extends component longevity, and reduces friction, resulting in improved overall performance. Industries such as automotive, aerospace, hydraulics, medical, and many more have embraced honing in machining to meet demanding requirements and ensure the reliability and longevity of their products.With increasing customer demands and evolving industry standards, the importance of honing in machining cannot be overstated. As manufacturers strive for excellence in quality and performance, honing in machining is an indispensable tool for achieving their goals. The ability to produce components with unmatched precision and exceptional surface finish gives companies a competitive advantage, boosting their reputation and driving growth.Moreover, honing in machining contributes to sustainable manufacturing practices. By optimizing component functionality and longevity, this technique reduces waste, improves energy efficiency, and minimizes the need for replacement parts. This results in cost savings and a reduced environmental footprint, making honing in machining an eco-friendly choice for forward-thinking manufacturers.Looking ahead, the future of honing in machining holds even more potential. Advancements in automation, artificial intelligence, and data analysis are set to revolutionize this field, enabling faster and more accurate results. With the ability to monitor and adapt machining parameters in real-time, honing machines will become even more versatile, efficient, and intelligent, driving precision manufacturing to new heights.In conclusion, honing in machining has emerged as a cutting-edge technique revolutionizing precision manufacturing. With its ability to achieve unparalleled surface finish, dimensional accuracy, and durability, honing in machining is helping industries worldwide meet demanding requirements and elevate their manufacturing processes to new levels. Companies like [Company Name] are at the forefront of this technological advancement, pushing boundaries and continuously innovating to provide exceptional solutions for the ever-evolving manufacturing landscape. As honing in machining continues to evolve, it is poised to play an even greater role in shaping the future of precision manufacturing.

Top Bore and Hone Machine for Precision Engine Work

Bore And Hone Machine Revolutionizing Manufacturing ProcessesIn the world of manufacturing, precision and accuracy are paramount. Companies are constantly seeking innovative solutions to ensure that their products are of the highest quality while also improving their operational efficiency. This is where the Bore And Hone Machine, provided by a leading engineering company, comes into play.With a commitment to delivering cutting-edge technologies, the engineering company has developed a state-of-the-art Bore And Hone Machine that has been revolutionizing the manufacturing industry. Their machine is designed to provide superior precision and consistency, making it an indispensable tool for companies across various sectors.The Bore And Hone Machine is equipped with advanced features that set it apart from traditional honing and boring equipment. It utilizes high-tech controls and automation systems to ensure that every task is performed with the highest level of accuracy. This machine is capable of honing and boring a wide range of materials, including steel, aluminum, and cast iron, making it a versatile solution for a variety of manufacturing needs.One of the key advantages of the Bore And Hone Machine is its ability to enhance productivity while maintaining exceptional quality. The machine's advanced capabilities enable it to complete tasks with utmost efficiency, reducing the time required for honing and boring processes. This not only translates to significant time and cost savings for manufacturers but also ensures that the end products meet the most stringent quality standards.Furthermore, the Bore And Hone Machine is designed for ease of use, allowing operators to program and control the machine with precision and simplicity. Its intuitive interface and user-friendly controls make it accessible to a wide range of operators, eliminating the need for extensive training and reducing the potential for human error.In addition to its technological prowess, the Bore And Hone Machine is backed by the engineering company's renowned expertise and commitment to customer satisfaction. With a proven track record of delivering high-quality engineering solutions, the company has earned the trust of manufacturers worldwide. They offer comprehensive support and maintenance services to ensure that their clients can maximize the potential of their Bore And Hone Machine, thereby contributing to their long-term success.The impact of the Bore And Hone Machine on the manufacturing industry is undeniable. Its ability to elevate the precision, efficiency, and quality of honing and boring processes has made it an invaluable asset for companies seeking to stay ahead in today's competitive market. As the demand for superior manufacturing solutions continues to grow, the Bore And Hone Machine stands out as a game-changing innovation that is propelling the industry toward a new era of excellence.In conclusion, the Bore And Hone Machine offered by the engineering company represents a paradigm shift in the manufacturing landscape. Its cutting-edge technology, unparalleled precision, and commitment to customer satisfaction make it a must-have for companies aiming to achieve the highest standards in their production processes. With its boundless potential to optimize manufacturing operations, the Bore And Hone Machine is poised to shape the future of the industry. For manufacturers striving for excellence, this innovative solution is undoubtedly a catalyst for success.

Discover the Process of Deep Hole Blind Hole Machining for Precision Manufacturing

Deep Hole Blind Hole Machining, also known as gun drilling, is a specialized process used to create holes that are deeper than they are wide in metal and other materials. This process is commonly used in industries such as aerospace, automotive, and medical, where precision and accuracy are crucial.One of the leading companies in the field of deep hole blind hole machining is {}, a global leader in the manufacturing and supply of cutting tools and solutions for various industries. With over 50 years of experience in the industry, {} has been at the forefront of developing innovative machining technologies to meet the increasing demands of its customers.Deep hole blind hole machining is a complex process that requires expertise and advanced machinery. It involves feeding a cutting tool with specially designed coolant through the workpiece to remove material and create a hole. This process is particularly challenging when it comes to blind holes, which are holes that do not go through the entire workpiece. The precision and accuracy required for deep hole blind hole machining make it essential to have the right tools and equipment.{} offers a wide range of cutting tools and solutions for deep hole blind hole machining, including gun drills, solid carbide drills, reamers, and BTA drilling systems. These tools are designed to meet the stringent requirements of the industry and deliver high performance and reliability.The company's expertise in deep hole blind hole machining is backed by its state-of-the-art manufacturing facilities and research and development capabilities. {} continuously invests in new technologies and processes to stay ahead of the curve and provide its customers with cutting-edge solutions.In addition to its technical expertise, {} also prides itself on its commitment to customer satisfaction. The company works closely with its customers to understand their specific needs and provide customized solutions that meet their requirements. Whether it's aerospace, automotive, medical, or any other industry, {} has the knowledge and experience to deliver the right tools and solutions for deep hole blind hole machining.With a global presence and a strong focus on innovation, {} is well-positioned to meet the growing demand for deep hole blind hole machining solutions. The company's dedication to quality and customer satisfaction makes it a trusted partner for industries around the world.In conclusion, deep hole blind hole machining is a critical process for industries that require precision and accuracy in creating deep, narrow holes. With its expertise, advanced technologies, and commitment to customer satisfaction, {} is a leading provider of cutting tools and solutions for deep hole blind hole machining. As industries continue to evolve and demand more complex machining solutions, {} is poised to remain at the forefront of innovation and continue providing the high-quality products and services it is known for.

Innovative Deep Drilling Machine Unveiled for High-Precision Drilling Operations

Technology has been advancing rapidly in recent years, and one of the most groundbreaking developments comes in the form of the Deep Drilling Machine. This advanced piece of equipment has the potential to revolutionize the way we approach deep drilling operations, making them more efficient, precise, and cost-effective.The Deep Drilling Machine is a product of innovation and research by a leading company in the field of drilling and excavation. With a strong focus on pushing the boundaries of technology and engineering, this company has been at the forefront of developing cutting-edge solutions for the mining, construction, and energy industries.The Deep Drilling Machine is the latest addition to the company's impressive portfolio of products, and it promises to deliver exceptional performance in deep drilling operations. With its state-of-the-art design and advanced features, this machine has the capability to drill deeper and with higher precision than ever before.One of the key features of the Deep Drilling Machine is its advanced drilling technology, which allows for smoother and more efficient drilling operations. This is made possible by the machine's high-powered drilling mechanism, which is capable of generating immense force to penetrate even the toughest of surfaces.Furthermore, the Deep Drilling Machine is equipped with cutting-edge sensors and monitoring systems that provide real-time data and feedback during drilling operations. This not only enhances the precision and accuracy of the drilling process but also allows for better control and management of the machine's performance.In addition to its advanced drilling capabilities, the Deep Drilling Machine also stands out for its robust and durable construction. Built to withstand the harshest of working conditions, this machine is designed to be reliable and long-lasting, ensuring that it can consistently deliver high performance over an extended period of time.The company behind the Deep Drilling Machine has a strong track record of delivering top-quality products and services to its clients. With a team of highly skilled engineers, technicians, and project managers, the company is well-equipped to provide comprehensive support and assistance for the installation, operation, and maintenance of its products.Furthermore, the company places a strong emphasis on innovation and continuous improvement, regularly investing in research and development to stay ahead of the curve in the industry. This commitment to innovation is reflected in the Deep Drilling Machine, which incorporates the latest technological advancements to offer best-in-class performance and reliability.In line with its commitment to sustainability and environmental responsibility, the company also ensures that its products, including the Deep Drilling Machine, adhere to the highest standards of efficiency and eco-friendliness. This not only benefits the environment but also helps clients reduce their operational costs and carbon footprint.The introduction of the Deep Drilling Machine has already generated significant interest and excitement within the industry, with many experts and professionals recognizing its potential to transform deep drilling operations. As the company continues to showcase the capabilities of this innovative machine, it is expected to set new benchmarks for efficiency, reliability, and performance in deep drilling applications.In conclusion, the Deep Drilling Machine represents a major technological breakthrough that has the potential to redefine the way deep drilling operations are carried out. With its advanced features, robust construction, and the strong backing of a leading company, this machine is poised to make a significant impact in the industry. As the company continues to push the boundaries of technology and engineering, the Deep Drilling Machine stands as a testament to its commitment to excellence and innovation.