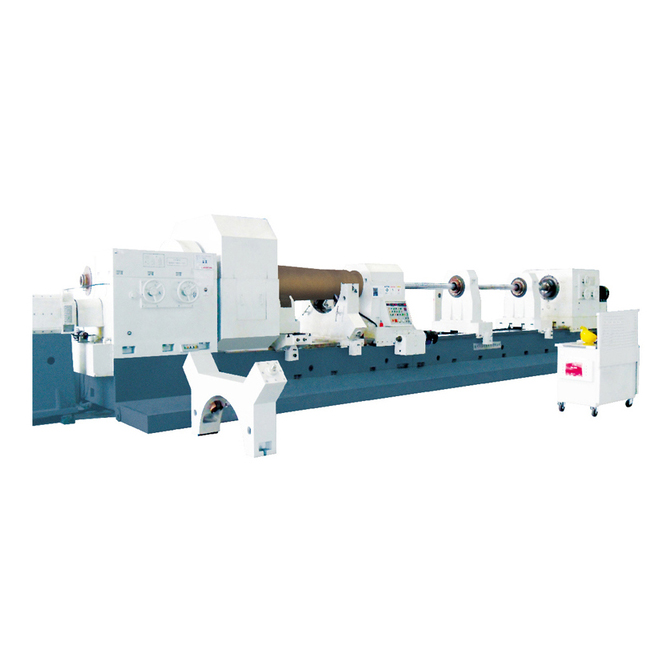

Powerful Engine Line Hone Machine for Precision Machining

By:Admin

In the ever-evolving world of automotive engineering, precision and efficiency are paramount. With the increasing demand for high-performance engines, manufacturers are constantly seeking innovative solutions to ensure top-notch quality and optimal functionality. One such solution is the Engine Line Hone Machine, a cutting-edge technology that has revolutionized engine manufacturing processes.

The Engine Line Hone Machine is a vital component in the production of high-quality engines. It is designed to precisely hone the bearing bores in engine blocks, thereby ensuring a perfect fit for the crankshaft bearings. This crucial process significantly contributes to the overall performance and longevity of the engine. By utilizing the latest advancements in engineering and technology, the Engine Line Hone Machine has become an indispensable tool for manufacturers seeking to achieve unparalleled precision and efficiency in their engine production processes.

One company at the forefront of this technological innovation is {}. With a longstanding reputation for excellence in the automotive industry, {} has consistently pushed the boundaries of engineering and manufacturing. Committed to delivering top-tier solutions to its clients, the company has embraced the Engine Line Hone Machine as an integral part of its production line. By incorporating this cutting-edge technology, {} has been able to streamline its engine manufacturing processes, resulting in higher precision, increased productivity, and superior quality.

The Engine Line Hone Machine offered by {} stands out for its exceptional performance and reliability. Equipped with advanced features and state-of-the-art capabilities, this machine is capable of achieving precise and consistent results, meeting the stringent requirements of modern engine manufacturing. Its user-friendly interface and intuitive controls make it easy to operate, while its robust construction ensures durability and longevity. With a focus on delivering unparalleled accuracy and efficiency, {} has established itself as a leading provider of Engine Line Hone Machines, catering to the diverse needs of automotive manufacturers worldwide.

In addition to its cutting-edge technology, {} places a strong emphasis on customer support and satisfaction. The company's team of skilled engineers and technical experts are dedicated to providing comprehensive assistance, from installation and training to ongoing maintenance and support. By offering a holistic approach to customer service, {} ensures that its clients are able to maximize the potential of the Engine Line Hone Machine, ultimately leading to a seamless and successful integration into their production processes.

The impact of the Engine Line Hone Machine on engine manufacturing has been significant. By enabling manufacturers to achieve unparalleled precision and consistency, this technology has led to the production of engines that are not only high-performing but also durable and reliable. With the ability to hone bearing bores with utmost accuracy, the Engine Line Hone Machine has become a cornerstone of modern engine production, playing a pivotal role in the quest for superior quality and performance.

Looking ahead, the future of engine manufacturing is poised for further advancements, and the Engine Line Hone Machine will undoubtedly continue to play a central role in this evolution. As automotive technology continues to progress, the demand for engines with uncompromising quality and precision will only increase. It is clear that the Engine Line Hone Machine will remain an indispensable tool for manufacturers seeking to stay ahead of the curve and deliver engines that meet the highest standards of excellence.

In conclusion, the Engine Line Hone Machine has reshaped the landscape of engine manufacturing, empowering companies like {} to elevate their production processes and deliver exceptional results. With its cutting-edge technology, unwavering commitment to quality, and comprehensive customer support, {} has proven itself as a driving force in the automotive industry. As the demand for high-performance engines continues to rise, the Engine Line Hone Machine will undoubtedly remain a cornerstone of innovation and precision in engine manufacturing.

Company News & Blog

High Quality Vertical Honing Machine for Precision Machining

Vertical Honing Machine Offers High-Level Precision and EfficiencyThe precision manufacturing industry has seen a significant increase in demand for high-quality honing machines. These machines are essential for achieving the precise surface finishes and sizing required for various industrial components, such as cylinders, gears, and hydraulic valves. With the increasing demand for precision engineering, the need for advanced honing solutions has become more prominent.One company that has been at the forefront of providing cutting-edge honing machines is {}. With over 20 years of experience in the manufacturing industry, {} has established itself as a leading provider of honing solutions. The company prides itself on its innovative approach to engineering and continuous commitment to delivering high-performance machines.One of the company's standout products is its Vertical Honing Machine, which has been designed to meet the increasing demands for precision and efficiency in honing operations. The machine offers a unique combination of advanced technology, superior build quality, and high-level precision, making it an ideal choice for a wide range of honing applications.The Vertical Honing Machine features a robust and rigid structure, which ensures stability and accuracy during the honing process. This rigidity is essential for achieving consistent and precise results, especially when honing complex geometries and tight tolerances. The machine's vertical design also allows for easy loading and unloading of workpieces, making it a highly efficient solution for high-volume production.One of the key features of {}'s Vertical Honing Machine is its advanced control system, which enables operators to fine-tune the honing process for optimal results. The machine is equipped with intuitive controls that allow for easy adjustment of honing parameters such as speed, pressure, and feed rate. This level of control is essential for achieving the desired surface finishes and sizing requirements, especially for critical components used in industries such as automotive, aerospace, and hydraulics.In addition to its precision and efficiency, the Vertical Honing Machine also offers versatility, allowing for a wide range of honing operations. Whether it's rough honing, finish honing, or sizing, the machine is capable of handling various honing processes with ease. This versatility makes it a valuable asset for manufacturers looking to streamline their honing operations and enhance overall productivity.Moreover, {} provides comprehensive support and service for its Vertical Honing Machine, ensuring that customers can maximize the machine's performance and longevity. The company's team of experienced engineers and technicians are readily available to provide installation, training, and maintenance services, further cementing {}'s commitment to customer satisfaction and success.With the increasing demands for precision and efficiency in the manufacturing industry, the Vertical Honing Machine from {} is poised to make a significant impact. Its advanced technology, high-level precision, and versatility make it an ideal solution for manufacturers looking to elevate their honing operations to new heights. As the industry continues to evolve, {} remains dedicated to providing cutting-edge honing solutions that empower manufacturers to achieve excellence in their production processes.

Advanced Six-Coordinate Deep Hole Drilling and Boring Machine for Precision Machining

Six-Coordinate CNC Deep Hole Drilling and Boring Machine Revolutionizes Precision EngineeringIn the world of precision engineering, the importance of accuracy, efficiency, and reliability cannot be overstated. From aerospace to automotive, the demand for high-quality components with intricate features continues to grow. In response to these demands, {company name} has introduced a groundbreaking solution - the Six-Coordinate CNC Deep Hole Drilling and Boring Machine.With its innovative design and cutting-edge technology, this machine has set a new standard in the industry. Equipped with six-coordinate capability, it offers unparalleled precision and flexibility, allowing for the creation of complex and precise deep holes and bores with ease.The {company name} Six-Coordinate CNC Deep Hole Drilling and Boring Machine is a game changer for manufacturers who require high-precision components. Its advanced CNC control system enables seamless programming and precise execution of drilling and boring operations, ensuring consistent and accurate results every time. This machine is capable of handling a wide range of materials, including metals, alloys, and composites, making it a versatile solution for various industries.One of the key features of the Six-Coordinate CNC Deep Hole Drilling and Boring Machine is its advanced cooling and chip removal system. This system ensures efficient heat dissipation during the drilling process, resulting in minimal distortion and superior surface finish. Additionally, the machine's chip removal system effectively evacuates chips from deep holes, preventing tool damage and ensuring smooth and uninterrupted operation.Another notable aspect of this machine is its modular design, which allows for easy customization and integration with existing manufacturing systems. This flexibility enables manufacturers to optimize their production processes and adapt to changing requirements, ultimately improving overall efficiency and productivity.Moreover, the Six-Coordinate CNC Deep Hole Drilling and Boring Machine is equipped with state-of-the-art safety features, ensuring the well-being of operators and the integrity of the work environment. With built-in monitoring and protection systems, the machine provides a safe and reliable operation, giving manufacturers peace of mind while achieving high-precision results.{Company name}'s commitment to quality and innovation is evident in the development of this cutting-edge machine. With a focus on precision engineering and customer satisfaction, {company name} has solidified its position as a leader in the industry. The Six-Coordinate CNC Deep Hole Drilling and Boring Machine is a testament to the company's dedication to pushing the boundaries of technology and delivering solutions that meet the evolving needs of modern manufacturing.The introduction of the Six-Coordinate CNC Deep Hole Drilling and Boring Machine has already generated considerable interest within the industry. Its potential to revolutionize precision engineering processes and elevate the quality of manufactured components has garnered attention from key players in various sectors, including aerospace, automotive, and mold making.In conclusion, {Company name} has set a new benchmark in precision engineering with the introduction of the Six-Coordinate CNC Deep Hole Drilling and Boring Machine. With its advanced capabilities, reliability, and versatility, this machine is poised to redefine the way manufacturers approach deep hole drilling and boring operations. As the industry continues to evolve, {company name} remains at the forefront, driving innovation and shaping the future of precision engineering.

High-Quality Motorcycle Cylinder Honing Machine for Sale

In the world of motorcycle manufacturing and maintenance, precision is paramount. From the smallest components to the largest engines, every detail must be perfect to ensure the safety and performance of these powerful machines. That's why {Company Name}, a leader in automotive equipment manufacturing, has developed a revolutionary Motorcycle Cylinder Honing Machine that is setting a new standard for precision and efficiency in the industry.With over 50 years of experience in the automotive equipment industry, {Company Name} has become a trusted name among motorcycle manufacturers and professional mechanics alike. The company's dedication to innovation and quality has made them a go-to source for cutting-edge equipment that meets the evolving needs of the industry.The Motorcycle Cylinder Honing Machine is the latest example of {Company Name}'s commitment to providing state-of-the-art solutions for motorcycle maintenance. This advanced machine is designed to precisely hone the cylinders of motorcycle engines, ensuring optimal performance and longevity. With its advanced technology and user-friendly interface, the honing machine is suitable for use in motorcycle manufacturing facilities, as well as motorcycle repair shops and service centers.One of the key features of the Motorcycle Cylinder Honing Machine is its precision honing capability, which ensures that the cylinders are perfectly machined to the exact specifications required for optimal performance. This level of precision is essential for ensuring that the engine operates at its best, delivering the power and reliability that motorcycle enthusiasts and professionals demand.In addition to its precision honing capability, the honing machine also offers a high level of efficiency and ease of use. Its intuitive interface and automated functions make it easy for operators to set up and operate the machine, saving valuable time and reducing the risk of errors. This efficiency is crucial for motorcycle manufacturers and service providers, who must meet tight production schedules and deliver top-quality workmanship.Another notable feature of the Motorcycle Cylinder Honing Machine is its versatility. With the ability to hone cylinders of various sizes and configurations, the machine is suitable for use with a wide range of motorcycle engines, including those with multiple cylinders and different bore sizes. This flexibility allows motorcycle manufacturers and service providers to use the honing machine for a variety of applications, streamlining their operations and reducing the need for multiple machines.{Company Name} also prides itself on providing excellent customer support and service. The company's team of experts is dedicated to helping customers get the most out of their equipment, providing training and technical assistance as needed. This commitment to customer satisfaction sets {Company Name} apart from its competitors, ensuring that customers can rely on the honing machine to meet their specific needs and exceed their expectations.Overall, the introduction of the Motorcycle Cylinder Honing Machine is a game-changer for the motorcycle manufacturing and maintenance industry. {Company Name} has once again demonstrated its commitment to innovation and quality, providing a cutting-edge solution that meets the evolving needs of the industry. With its precision, efficiency, versatility, and excellent customer support, the honing machine is poised to become an essential tool for motorcycle manufacturers and service providers around the world.{Company Name} continues to lead the way in automotive equipment manufacturing, and the Motorcycle Cylinder Honing Machine is just the latest example of the company's dedication to excellence. As the industry continues to evolve, {Company Name} will no doubt continue to play a crucial role in shaping its future, providing the solutions and support that motorcycle manufacturers and professionals need to succeed.

Discover the Latest Deep Hole Machine Tools for Industrial Applications

Deep Hole Machine Tools is a leading manufacturer of advanced deep hole drilling machines and tools, catering to a wide range of industries including aerospace, automotive, defense, and oil & gas. With a strong focus on precision, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses worldwide.The company offers a diverse portfolio of deep hole drilling solutions, including gun drilling machines, BTA drilling machines, and ejector drilling machines. These machines are designed to meet the complex and demanding requirements of deep hole drilling, providing high accuracy, efficiency, and reliability in the production process.Deep Hole Machine Tools has a rich history of technological innovation and continuous improvement, leveraging cutting-edge engineering and manufacturing techniques to develop advanced solutions for its customers. The company's R&D team is comprised of industry experts and engineers who are dedicated to pushing the boundaries of deep hole drilling technology, staying ahead of market trends and anticipating the evolving needs of customers.In addition to its extensive product range, Deep Hole Machine Tools also offers custom engineering and consulting services, collaborating closely with clients to understand their specific requirements and provide tailored solutions that meet their unique challenges. This customer-centric approach has earned the company a strong reputation for excellence and reliability in the industry.With a global presence, Deep Hole Machine Tools has established a network of distributors and service centers in key regions around the world, ensuring timely support and assistance for its customers. This commitment to customer service, combined with the company's technical expertise, has positioned Deep Hole Machine Tools as a preferred partner for businesses seeking high-quality deep hole drilling solutions.In recent news, Deep Hole Machine Tools has announced the launch of its latest innovation, the XYZ-5000 series deep hole drilling machine. Featuring state-of-the-art technology and performance enhancements, the XYZ-5000 series is designed to deliver superior accuracy, speed, and versatility in deep hole drilling applications. With a focus on user-friendly operation and advanced control capabilities, the new machine is expected to set new standards in the industry and provide customers with a competitive edge in their operations."We are thrilled to introduce the XYZ-5000 series deep hole drilling machine to the market," said the CEO of Deep Hole Machine Tools. "This machine represents the culmination of our extensive R&D efforts and our commitment to delivering cutting-edge solutions to our customers. We believe that the XYZ-5000 series will empower businesses to achieve new levels of productivity and precision in their deep hole drilling processes."The XYZ-5000 series deep hole drilling machine is equipped with advanced features such as a high-speed drilling spindle, linear motor technology, and intelligent automation capabilities. These innovations enable the machine to achieve faster cycle times, higher drilling depths, and improved tool life, making it suitable for a wide range of applications in various industries.To support the launch of the XYZ-5000 series, Deep Hole Machine Tools is offering comprehensive training programs and technical support services for its customers, ensuring a seamless integration and optimal utilization of the new machine. The company is also providing customization options and retrofitting services to meet specific customer requirements and enhance the capabilities of existing deep hole drilling equipment.As Deep Hole Machine Tools continues to drive innovation and excellence in deep hole drilling technology, the company remains committed to its core values of quality, integrity, and customer satisfaction. With its latest product offering and unwavering dedication to customer success, Deep Hole Machine Tools is poised to solidify its position as a leader in the global deep hole drilling market.

Latest Line Hone Machine Offers Precision Results for Industry Needs

Line Hone Machine Enhances Precision and Efficiency in Automotive IndustryThe automotive industry is continually evolving, and with this evolution comes the demand for higher precision and efficiency in manufacturing processes. One company that has taken a proactive approach to meeting this demand is [Company Name], a leading provider of innovative machinery for the automotive industry. [Company Name] has recently introduced a cutting-edge Line Hone Machine that is revolutionizing the way automotive components are manufactured.The new Line Hone Machine from [Company Name] is designed to provide precise and efficient honing of automotive components, such as engine blocks, cylinder heads, and crankshafts. This state-of-the-art machine utilizes advanced technology to ensure that the honing process is carried out with the highest level of accuracy, resulting in superior quality components for the automotive industry.One of the key features of the Line Hone Machine is its ability to deliver consistent and precise honing results, even on complex and intricate automotive components. This is achieved through the machine's advanced control systems and high-quality abrasives, which work together to maintain tight tolerances and achieve the desired surface finish. As a result, manufacturers can produce automotive components with exceptional precision and efficiency, leading to improved overall quality and performance.In addition to its precision capabilities, the Line Hone Machine also offers enhanced efficiency in the manufacturing process. With its streamlined operation and rapid honing speeds, the machine is able to significantly reduce production times and increase output levels for automotive component manufacturers. This not only improves overall productivity but also allows manufacturers to meet the growing demand for high-quality automotive components in a timely manner.[Company Name] takes pride in its commitment to innovation and customer satisfaction. The Line Hone Machine is a testament to this commitment, as it represents the company's dedication to providing cutting-edge solutions that address the evolving needs of the automotive industry. By offering a machine that combines precision, efficiency, and reliability, [Company Name] is empowering manufacturers to elevate their production capabilities and deliver top-quality automotive components to the market.Furthermore, [Company Name] provides comprehensive support and training for its Line Hone Machine, ensuring that manufacturers are able to maximize the machine's potential and optimize their honing processes. The company's team of experienced technicians and engineers are readily available to assist customers with machine installation, operation, and maintenance, ultimately contributing to a seamless and efficient production environment.The automotive industry is highly competitive, and manufacturers are constantly seeking ways to differentiate themselves and gain a competitive edge. The Line Hone Machine from [Company Name] presents an opportunity for manufacturers to elevate their manufacturing capabilities and deliver superior automotive components that meet and exceed industry standards.In conclusion, the introduction of the Line Hone Machine by [Company Name] represents a significant advancement in the automotive manufacturing industry. By offering a machine that combines precision, efficiency, and reliability, [Company Name] is empowering manufacturers to elevate their production capabilities and deliver top-quality automotive components to the market. As the automotive industry continues to evolve, [Company Name] remains committed to providing innovative solutions that meet the evolving needs of manufacturers, ultimately contributing to the advancement of the industry as a whole.

High-Quality Hole Drilling Machine for Precision Work

Hole Drilling Machine, a company specializing in precision drilling solutions, has recently introduced a new state-of-the-art drilling machine that promises to revolutionize the industry. This innovative machine, which has not been named yet, is designed to offer unmatched accuracy and efficiency, making it an ideal choice for a wide range of drilling applications.The new drilling machine features advanced technology that allows for precise drilling of holes in various materials, including metal, wood, and plastic. Its high-speed drilling capability ensures quick and precise results, making it suitable for both small-scale and large-scale industrial operations.One of the key highlights of the new drilling machine is its versatility. With its adjustable drilling parameters, it can accommodate a wide range of hole sizes and shapes, making it a versatile tool for various drilling requirements. This flexibility makes it a valuable asset for businesses that need to handle diverse drilling tasks with a single machine.In addition to its exceptional drilling capabilities, the new machine is also designed for ease of use and operator safety. Its user-friendly interface and ergonomic design make it easy for operators to set up and control, while its safety features ensure that the drilling process is carried out without risk to the operators."We are thrilled to introduce this new drilling machine to the market," said a spokesperson from Hole Drilling Machine. "We believe that this machine will set a new standard for precision drilling, offering our customers a reliable and efficient solution for their drilling needs."Hole Drilling Machine has a strong reputation in the industry for delivering high-quality drilling solutions. With a focus on innovation and customer satisfaction, the company has consistently been at the forefront of developing cutting-edge drilling technologies that meet the evolving needs of the industry.The company's commitment to excellence is reflected in its dedication to research and development. Hole Drilling Machine invests heavily in R&D to ensure that its products are equipped with the latest advancements in drilling technology, maintaining its position as a leader in the industry.In addition to its innovative product line, Hole Drilling Machine also prides itself on providing exceptional customer service. The company's team of experts works closely with clients to understand their specific drilling requirements and offer tailored solutions that meet their needs effectively.With the introduction of the new drilling machine, Hole Drilling Machine aims to further strengthen its position in the market and continue to be a reliable partner for businesses seeking high-quality drilling solutions. The company is confident that the new machine will be well-received by industries that rely on precision drilling for their operations.As industries continue to demand greater efficiency and accuracy in their drilling processes, the new drilling machine from Hole Drilling Machine is poised to make a significant impact. By offering unmatched precision, versatility, and user-friendly operation, the machine is set to become a game-changer in the drilling industry.In conclusion, the new drilling machine from Hole Drilling Machine represents a significant step forward in the realm of precision drilling. With its advanced technology, versatility, and user-friendly design, it is poised to set a new standard for drilling machines, offering businesses a reliable and efficient solution for their drilling needs. As the industry continues to evolve, Hole Drilling Machine remains committed to delivering innovative solutions that meet the demands of the market, reinforcing its position as a leader in the drilling industry.

How to Sharpen Gun Drills with a Drill Sharpening Machine

Gun Drill Sharpening Machine, a new product recently launched by [Company Name], is set to revolutionize the precision engineering industry. The machine is designed to provide accurate and efficient sharpening of gun drills, ensuring optimal performance and longevity. With a focus on precision and reliability, [Company Name] has introduced this cutting-edge technology to cater to the needs of the manufacturing sector, particularly in the field of metalworking and aerospace.[Company Name] is a leading manufacturer of machinery and equipment for the metalworking industry, with a strong focus on innovation and quality. With a rich history spanning over three decades, [Company Name] has established itself as a trusted name in the industry, known for its commitment to excellence and customer satisfaction. The introduction of the Gun Drill Sharpening Machine is a testament to the company's dedication to meeting the evolving needs of its clients and staying ahead of the curve in technological advancements.The Gun Drill Sharpening Machine is the result of extensive research and development, aimed at addressing the challenges faced by manufacturers in sharpening gun drills with precision and consistency. The machine is equipped with state-of-the-art technology and features, including advanced sharpening mechanisms and user-friendly controls, ensuring ease of operation and high precision sharpening. This innovative solution is set to streamline the sharpening process, ultimately leading to improved productivity and cost efficiency for manufacturers.One of the key highlights of the Gun Drill Sharpening Machine is its ability to accommodate a wide range of gun drill sizes and specifications, making it a versatile and practical tool for manufacturers with diverse needs. This adaptability is a major advantage for companies dealing with various types of gun drills, allowing them to streamline their sharpening processes and eliminate the need for multiple machines or manual adjustments. As a result, manufacturers can expect to enhance their operational efficiency and maintain the quality of their gun drills with minimal downtime.In addition to its technical capabilities, the Gun Drill Sharpening Machine is built to withstand the rigors of industrial use, with a robust and durable construction that prioritizes longevity and reliability. This aspect reflects [Company Name]'s commitment to delivering products that not only meet the immediate needs of its clients but also offer long-term value and performance. The machine's design also takes into account the importance of safety in industrial settings, incorporating features that promote secure and efficient operation.Furthermore, [Company Name] provides comprehensive support and maintenance services for the Gun Drill Sharpening Machine, ensuring that clients can maximize the benefits of this innovative solution with ongoing technical assistance and expertise. This commitment to customer satisfaction is a hallmark of [Company Name]'s approach to business, fostering strong and lasting relationships with its clients based on trust, reliability, and superior service.The introduction of the Gun Drill Sharpening Machine marks a significant milestone for [Company Name] and underscores its position as a leader in providing cutting-edge solutions for the metalworking industry. With a strong emphasis on precision, reliability, and practicality, this new addition to the company's product lineup is poised to make a tangible impact on the efficiency and quality of gun drill sharpening processes for manufacturers. As [Company Name] continues to innovate and evolve, it remains dedicated to empowering its clients with the latest advancements in technology, setting new standards for excellence in precision engineering.

The Ultimate Guide to Single Cylinder Honing Machines: Everything You Need to Know

Single Cylinder Honing Machine: The Latest Addition to the Product Line of a Leading Manufacturing Company{Company Name}, a renowned manufacturer of precision tools and equipment, has recently announced the launch of their latest product, the Single Cylinder Honing Machine. This cutting-edge machine is designed to provide superior honing and surface finishing capabilities for a wide range of industrial applications. With over {number} years of experience in the manufacturing industry, {Company Name} has earned a reputation for delivering high-quality products that meet the diverse needs of their customers.The Single Cylinder Honing Machine is the result of extensive research and development efforts by {Company Name}'s team of skilled engineers and technicians. It is specifically engineered to offer precision honing for single cylinder engine blocks, ensuring optimal surface quality and dimensional accuracy. The machine boasts advanced features such as high-precision honing tools, a robust honing spindle, and a user-friendly control interface, making it an ideal choice for manufacturers seeking to enhance the performance and durability of their engine components.One of the key highlights of the Single Cylinder Honing Machine is its versatility, as it can accommodate a wide range of bore sizes and materials, including cast iron, steel, aluminum, and other alloys. This flexibility allows manufacturers to hone different types of engine blocks and cylinders with ease, thereby streamlining their production processes and improving overall efficiency. Additionally, the machine's automated honing cycle and integrated coolant system ensure consistent performance and prolonged tool life, contributing to cost savings and higher productivity.In line with {Company Name}'s commitment to customer satisfaction, the Single Cylinder Honing Machine is backed by comprehensive technical support and after-sales service. The company's team of experts is readily available to provide assistance with installation, training, and troubleshooting, ensuring that customers can maximize the potential of the machine and achieve optimal results in their operations. Furthermore, {Company Name} offers customizable tooling solutions and honing parameters to suit specific manufacturing requirements, further enhancing the value proposition of the Single Cylinder Honing Machine."We are thrilled to introduce the Single Cylinder Honing Machine to the market, as it represents a significant advancement in our product portfolio," said {Spokesperson Name}, the CEO of {Company Name}. "This machine exemplifies our dedication to innovation and excellence, and we are confident that it will empower our customers to elevate their honing processes and achieve superior surface finishes for their engine components."The launch of the Single Cylinder Honing Machine underscores {Company Name}'s ongoing commitment to meeting the evolving needs of the manufacturing industry and delivering cutting-edge solutions that drive operational efficiency and quality performance. With its proven track record of providing reliable and technologically advanced equipment, {Company Name} continues to be a trusted partner for businesses seeking to elevate their manufacturing capabilities and stay ahead in a competitive market landscape.To learn more about the Single Cylinder Honing Machine and other products offered by {Company Name}, interested parties can visit the company's website or contact their sales representatives for personalized consultations and demonstration sessions. As the manufacturing industry continues to evolve, {Company Name} remains at the forefront, providing innovative solutions that empower businesses to thrive and succeed in a dynamic market environment.

Efficient Honing Machines for Precision Metal Finishing - A Promising Breakthrough in Manufacturing Technology

Precision Honing Machine Leads the Way in Innovation and QualityPrecision Honing Machine, a leading manufacturer in the field of honing equipment, continues to deliver cutting-edge solutions that redefine the industry standards. With a focus on innovation, quality, and customer satisfaction, Precision Honing Machine has established itself as a trusted name in the global market.Founded in [year], Precision Honing Machine has been dedicated to developing and producing high-precision honing machines that cater to a wide range of industries, including automotive, aerospace, hydraulic cylinders, and defense. The company's commitment to research and development ensures that their machines are at the forefront of technological advancement, enabling customers to boost productivity and improve efficiency in their operations.At the heart of Precision Honing Machine's success is their team of highly skilled engineers and technicians who possess deep expertise in the honing industry. They constantly strive to design and manufacture machines that meet the evolving needs of customers in today's dynamic market. By leveraging the latest technologies and employing rigorous quality control measures, the company ensures that every honing machine that leaves their production line is reliable, durable, and of exceptional performance.One of Precision Honing Machine's flagship products is the [model name], which has garnered widespread acclaim for its superior precision and efficiency. Equipped with state-of-the-art features and functionalities, this machine offers unparalleled control and accuracy, resulting in an impeccable surface finish. The [model name] is designed to meet the diverse needs of various industries and can efficiently hone materials ranging from metals to ceramics.The key differentiating factor that sets Precision Honing Machine apart from its competitors is its unwavering commitment to customer satisfaction. The company takes a customer-centric approach, working closely with clients to understand their specific requirements. By doing so, they are able to tailor their solutions to offer a truly bespoke experience. Additionally, Precision Honing Machine provides comprehensive after-sales support, including installation, training, and maintenance services, ensuring that customers derive maximum value from their investment.In an increasingly competitive market, Precision Honing Machine consistently strives to stay ahead of the curve through continuous innovation. The company invests heavily in research and development, collaborating with renowned industry experts and academic institutions to explore cutting-edge technologies. This commitment has resulted in several groundbreaking advancements, enabling Precision Honing Machine to maintain its position as an industry pioneer.Furthermore, Precision Honing Machine adheres to stringent quality control processes, ensuring that their products pass rigorous tests before they are delivered to customers. By doing so, they maintain exceptional standards, providing customers with reliable machines that outperform their expectations. This commitment to quality has earned Precision Honing Machine numerous certifications and accolades, further solidifying its reputation as a trusted supplier in the honing industry.Looking to the future, Precision Honing Machine aims to continue pushing the boundaries of honing technology, providing even more efficient, precise, and innovative solutions. The company seeks to expand its global presence by forging strategic partnerships and strengthening its distribution network. Moreover, Precision Honing Machine remains committed to sustainability, with a focus on developing eco-friendly machines and implementing green manufacturing practices.In conclusion, Precision Honing Machine has proven itself to be a leading force in the honing industry through its dedication to innovation, quality, and customer satisfaction. With a team of experienced engineers, a range of cutting-edge products, and a customer-centric approach, Precision Honing Machine is well-positioned to shape the future of honing technology.

Top Drilling Company Delivers Quality Services for Various Industries

BTA Drilling Company, a leading provider of drilling solutions, has announced its latest innovation in the oil and gas industry. The company has recently introduced a groundbreaking new technology that is set to revolutionize the way drilling operations are carried out.The new technology, which the company has been developing for the past few years, is a game-changer in the field of drilling. It promises to significantly increase efficiency and productivity while minimizing the environmental impact of drilling operations.BTA Drilling Company has always been at the forefront of innovation in the industry. With a strong focus on research and development, the company has continually strived to push the boundaries of what is possible in drilling technology. This latest breakthrough is a testament to the company's commitment to driving positive change in the industry.The new technology is a result of years of research and development, combined with the expertise of BTA Drilling Company's team of engineers and scientists. It is designed to address some of the most pressing challenges in the industry, such as the need for more sustainable and environmentally friendly drilling methods.One of the key features of the new technology is its ability to significantly reduce the environmental impact of drilling operations. By incorporating advanced filtration and recycling systems, the technology is able to minimize the amount of waste generated during drilling. This is a major step forward in making drilling operations more sustainable and in line with environmental regulations.In addition to its environmental benefits, the new technology also promises to increase efficiency and productivity in drilling operations. With its advanced automation and monitoring systems, the technology streamlines the drilling process, allowing for faster and more accurate operations. This ultimately results in cost savings for drilling companies and increased output.BTA Drilling Company's new technology has already garnered significant interest from industry leaders and experts. Many are touting it as a potential game-changer in the industry, with the potential to set new standards for drilling operations."We are thrilled to introduce this groundbreaking new technology to the industry," said the CEO of BTA Drilling Company. "We believe that it has the potential to revolutionize the way drilling operations are carried out, paving the way for a more sustainable and efficient future for the industry."The introduction of this new technology comes at a critical time for the oil and gas industry, as companies are increasingly under pressure to adopt more sustainable and environmentally friendly practices. With the new technology from BTA Drilling Company, companies now have a viable solution to meet these demands without compromising on productivity and efficiency.The company is currently in the process of deploying the new technology in various drilling operations around the world. Initial feedback from these deployments has been overwhelmingly positive, with companies reporting significant improvements in efficiency and sustainability.As the industry eagerly awaits the widespread adoption of this groundbreaking new technology, BTA Drilling Company continues to lead the way in driving innovation and positive change in the industry. With its forward-thinking approach and commitment to excellence, the company is well-positioned to continue making a significant impact in the field of drilling.