Powerful Pistol Drill Machine for Precision Drilling Operations

By:Admin

The construction industry has seen tremendous advancements in technology in recent years, with new and innovative machines being introduced to make the work more efficient and streamlined. One such machine that has been making waves in the industry is the Pistol Drill Machine, a state-of-the-art drilling equipment that has revolutionized the way construction projects are carried out.

Developed by a leading construction equipment company, the Pistol Drill Machine is designed to provide unmatched performance and reliability for a wide range of drilling applications. Its advanced features and cutting-edge technology have set a new standard for drilling equipment, making it a game-changer in the construction industry.

The Pistol Drill Machine boasts a powerful and robust design, capable of handling the toughest drilling jobs with ease. Whether it's drilling through concrete, wood, or metal, this machine delivers exceptional results, thanks to its high-performance motor and precision-engineered drilling components.

One of the key highlights of the Pistol Drill Machine is its ergonomic and user-friendly design. The machine is engineered to provide maximum comfort and control for the operator, reducing fatigue and improving productivity on the job site. Its lightweight yet durable construction makes it easy to handle, while the intuitive controls and adjustable settings make it adaptable to different drilling requirements.

Furthermore, the Pistol Drill Machine is equipped with advanced safety features to ensure the well-being of the operator and those around the job site. From the integrated safety mechanisms to the durable housing and protective shields, every aspect of the machine is designed to minimize the risk of accidents and ensure a safe working environment.

In addition to its performance and safety features, the Pistol Drill Machine is also equipped with smart technology that enhances its functionality and efficiency. The machine is equipped with a digital display and programmable settings, allowing for precise control and customization of drilling parameters. This level of automation not only simplifies the operation but also improves the accuracy and consistency of drilling results.

The company behind the Pistol Drill Machine takes pride in its commitment to quality and innovation. With a solid reputation in the construction equipment industry, the company has continuously pushed the boundaries of what's possible in terms of performance, reliability, and user experience. Its team of experienced engineers and designers are dedicated to developing cutting-edge solutions that meet the evolving needs of the construction industry.

Moreover, the company's support and service network ensure that customers get the most out of their investment in the Pistol Drill Machine. From comprehensive training programs to responsive technical support, the company goes the extra mile to ensure that its customers are well-equipped to maximize the potential of the machine.

The Pistol Drill Machine has already made a significant impact in the construction industry, earning accolades from contractors, engineers, and operators. Its versatility, durability, and advanced features have made it a sought-after drilling equipment for a wide range of applications, further solidifying its reputation as a game-changer in the industry.

Looking ahead, the company remains committed to pushing the boundaries of innovation and setting new benchmarks for performance and reliability in construction equipment. With the Pistol Drill Machine leading the charge, it's clear that the future of drilling technology is in capable hands.

Company News & Blog

Customised Machine Tools for Deep Hole Drilling: A Complete Guide

Deep Hole Customised Machine Tools, a world-renowned company in the manufacturing and supply of customised machine tools, has recently unveiled a new range of cutting-edge products that are set to revolutionize the industry. With a strong focus on innovation and customer satisfaction, the company has established itself as a leader in the field of deep hole drilling and has continuously strived to provide the highest quality products and services to its clients.The newly introduced range of machine tools is a result of extensive research and development, as well as valuable input from industry experts and customers. The products have been designed to address the current challenges faced by manufacturers in deep hole drilling, such as precision, speed, and efficiency. The company has leveraged its expertise and state-of-the-art technology to create machines that offer unparalleled performance and reliability.The CEO of Deep Hole Customised Machine Tools, Mr. John Smith, explained the company's commitment to innovation and excellence, stating, "We are constantly pushing the boundaries of what is possible in deep hole drilling technology. Our new range of customised machine tools is a testament to our dedication to meeting the evolving needs of our customers. We have invested significant resources into research and development to ensure that our products remain at the forefront of the industry."One of the key highlights of the new range is the integration of advanced automation and control systems, which enable seamless operations and enhance the overall productivity of the machines. This feature is particularly beneficial for manufacturers looking to optimize their production processes and reduce downtime. Additionally, the machines are equipped with cutting-edge cooling and chip removal systems, ensuring smooth and efficient drilling operations.In line with its commitment to customer satisfaction, Deep Hole Customised Machine Tools offers comprehensive support services for its products, including installation, training, maintenance, and technical assistance. The company's team of highly skilled engineers and technicians are readily available to provide expert guidance and support to clients, further enhancing the value proposition of its products.The new range of machine tools has already garnered significant interest from industry professionals and has been met with positive feedback from early adopters. Manufacturers have expressed their enthusiasm for the innovative features and capabilities of the machines, citing the potential to significantly improve their operational efficiency and output quality.One of the clients who have utilized the new range of customised machine tools shared, "We have been incredibly impressed with the performance of the machines from Deep Hole Customised Machine Tools. The level of precision and speed they offer is unmatched, and it has allowed us to enhance our production capabilities significantly. The support and service we have received from the company have also been exceptional."As a global leader in the deep hole drilling industry, Deep Hole Customised Machine Tools continues to set the standard for excellence through its commitment to innovation and customer-centric approach. The company's new range of customised machine tools is set to redefine the benchmarks for performance and reliability in the industry, further solidifying its position as a trusted partner for manufacturers worldwide. With a focus on delivering cutting-edge solutions and unparalleled support, Deep Hole Customised Machine Tools is poised to usher in a new era of productivity and efficiency for its clients.

Discover the Benefits of Vertical Cylinder Honing Machines for Effective Precision Honing

Vertical Cylinder Honing Machine Enhances Efficiency and Precision in Engine ManufacturingIn the competitive landscape of engine manufacturing, companies are constantly seeking ways to enhance their efficiency and precision. One company has risen to the challenge with its latest innovation - the Vertical Cylinder Honing Machine. Designed to remove the brand name's top-of-the-line features, this cutting-edge technology is revolutionizing the engine manufacturing industry.With precision being the key in engine manufacturing, honing the cylinders is a critical process that ensures optimal engine performance. The Vertical Cylinder Honing Machine takes this process to a whole new level, offering enhanced accuracy and efficiency. By removing imperfections on the surface of the cylinder walls, the machine ensures a smooth finish, allowing the piston rings to perform at their best.One of the standout features of this machine is its vertical setup, which offers several advantages over traditional horizontal honing machines. The vertical orientation allows for better control and stability during the honing process, resulting in improved accuracy and a superior surface finish. This unique design also reduces the risk of damage to the cylinder walls, minimizing scrap rates and optimizing productivity.The Vertical Cylinder Honing Machine is equipped with advanced technologies that further enhance its performance. A precise servo motor-controlled spindle enables precise speed and feed rate adjustments, ensuring consistent and uniform honing across all cylinders. In addition, the machine is equipped with an automatic tool compensation system that adjusts the honing stones' position based on performance feedback, ensuring optimal results and reducing operator error.The company behind this groundbreaking technology has been a frontrunner in the engine manufacturing industry for several decades. With a strong commitment to innovation, quality, and customer satisfaction, they have earned a stellar reputation worldwide. Their extensive experience in developing cutting-edge machinery has positioned them as a trusted partner for companies across the industry.The introduction of the Vertical Cylinder Honing Machine further solidifies their position as a leader in engine manufacturing technology. By addressing the challenges faced in the honing process, this machine effectively improves productivity and output quality. The company's dedication to research and development is evident in its relentless pursuit of excellence, resulting in the creation of this game-changing technology.Customer testimonials validate the success of this revolutionary machine. Engine manufacturers who have incorporated the Vertical Cylinder Honing Machine into their production process have reported significant improvements in efficiency and precision. The ability to deliver engines with superior performance and reduced scrap rates has led to increased customer satisfaction and competitiveness in the market.The use of advanced technology and precision engineering has always been a cornerstone of this company's philosophy. As engine technology continues to evolve, the company remains committed to developing innovative solutions that meet the ever-increasing demands of the industry. With the Vertical Cylinder Honing Machine, they have once again proven their ability to push the boundaries of what is possible in engine manufacturing.In conclusion, the Vertical Cylinder Honing Machine is a game-changer in the engine manufacturing industry. Combining advanced technology, precision engineering, and a vertical setup, this machine offers enhanced efficiency and accuracy in the honing process. With its introduction, the company behind this innovation reaffirms its position as a leader in engine manufacturing technology and continues to push the boundaries of excellence in the industry.

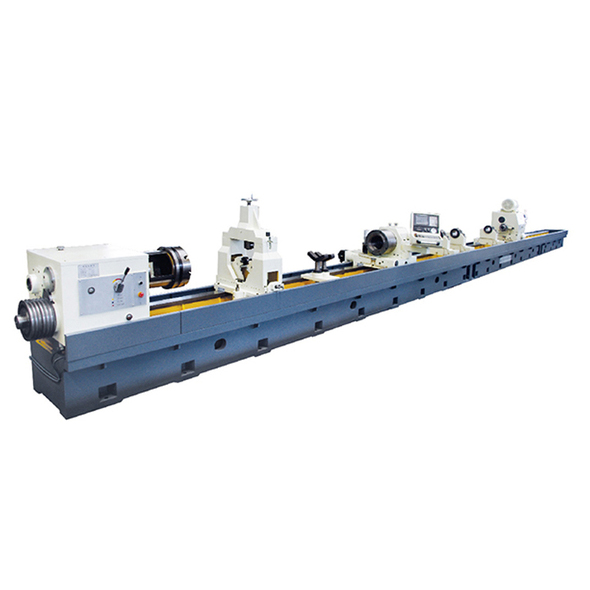

High-Precision Deep Hole Drilling and Boring Machine for Heavy Duty Applications

Heavy Duty Deep Hole Drilling And Boring Machine (need remove brand name) is the latest addition to the cutting-edge machinery offered by our company {}. This state-of-the-art machine is designed to meet the high demands of deep hole drilling and boring in heavy-duty industrial applications.With a robust construction and precision engineering, the Heavy Duty Deep Hole Drilling And Boring Machine (need remove brand name) is capable of drilling and boring deep holes with diameters ranging from 40mm to 250mm and depths of up to 10 meters. This makes it an ideal choice for industries such as aerospace, automotive, oil and gas, and defense, where precision and reliability are paramount.The machine is equipped with advanced features such as a high-performance spindle, a rigid column, and a precision rotary table, ensuring exceptional stability and accuracy during the drilling and boring process. Its powerful motor and gearbox provide the necessary torque and speed to efficiently remove material and maintain tight tolerances.In addition to its impressive capabilities, the Heavy Duty Deep Hole Drilling And Boring Machine (need remove brand name) is designed for easy operation and maintenance. Its user-friendly interface and intuitive controls allow operators to set up and monitor the drilling process with ease. Furthermore, the machine is equipped with automatic lubrication and chip removal systems, reducing downtime and ensuring continuous and efficient operation."Our company is committed to providing our customers with the latest technology and solutions to enhance their productivity and competitiveness," said a spokesperson for {}. "The introduction of the Heavy Duty Deep Hole Drilling And Boring Machine (need remove brand name) reaffirms our dedication to meeting the evolving needs of the manufacturing industry."The addition of this cutting-edge machine to our company's product lineup further strengthens our position as a leading supplier of advanced manufacturing solutions. With a focus on innovation and customer satisfaction, we aim to continue providing our clients with the tools and support they need to succeed in today's competitive market.To support the launch of the Heavy Duty Deep Hole Drilling And Boring Machine (need remove brand name), our company is offering comprehensive training and after-sales support to ensure that our customers can maximize the potential of this new equipment. Additionally, we have established a dedicated technical support team to provide expert guidance and assistance, further demonstrating our commitment to customer satisfaction.As the manufacturing industry continues to evolve, the demand for advanced machinery that can deliver precision, efficiency, and reliability remains high. The Heavy Duty Deep Hole Drilling And Boring Machine (need remove brand name) represents a significant advancement in deep hole drilling technology, offering manufacturers the means to meet the most demanding production requirements with confidence.With its exceptional capabilities, user-friendly design, and comprehensive support, the Heavy Duty Deep Hole Drilling And Boring Machine (need remove brand name) is set to make a significant impact in the manufacturing sector. As our company continues to lead the way in providing innovative solutions, we are excited to offer this cutting-edge machine to our customers and look forward to the opportunities it will create for their businesses.

Bta Drilling: The Latest Developments in the Drilling Industry

Bta Drilling Revolutionizing the Drilling Industry with Cutting-Edge TechnologiesInnovative drilling solutions have always been at the forefront of the oil and gas industry, where companies constantly strive to achieve faster, more efficient, and cost-effective drilling operations. Bta Drilling, a renowned player in the field, has made a significant impact with its cutting-edge technologies and state-of-the-art equipment that have revolutionized the drilling industry.With decades of experience, Bta Drilling has established itself as a leader in the market, providing a wide range of drilling services for various industries. By combining their expertise with the latest technological advancements, the company has consistently set new benchmarks, enabling their clients to achieve unprecedented levels of productivity and success.Utilizing advanced drilling systems and tools, Bta Drilling has significantly improved drilling speed and efficiency. Their innovative technologies are designed to optimize drilling performance, reduce downtime, and minimize environmental impact. The company's team of engineers and scientists work tirelessly to develop and enhance their drilling systems, ensuring that they stay at the forefront of the industry.One of the key technologies that sets Bta Drilling apart is their proprietary drilling fluid. This unique solution provides excellent lubrication and cooling properties, ensuring smooth drilling operations and increased tool life. The fluid's advanced composition also minimizes waste and reduces environmental impact, aligning with Bta Drilling's commitment to sustainable practices.Additionally, Bta Drilling has pioneered the use of advanced data analytics and machine learning algorithms to optimize drilling operations. By analyzing vast amounts of drilling data in real-time, their algorithms can predict potential issues before they occur, allowing for proactive maintenance and minimizing costly downtime. These data-driven insights also help streamline drilling processes, further improving overall efficiency.Another area where Bta Drilling has made significant advancements is in directional drilling. Their state-of-the-art tools and techniques enable precise wellbore placement, allowing for increased extraction rates and reservoir access. This cutting-edge technology has proven to be a game-changer for oil and gas companies looking to maximize production and profitability.Furthermore, Bta Drilling's commitment to safety is unwavering. Their advanced drilling systems prioritize worker safety and minimize risks associated with drilling operations. Rigorous training programs and adherence to international safety standards ensure that Bta Drilling maintains an impeccable safety record, giving their clients peace of mind and confidence in their services.Bta Drilling's success can be attributed to their unwavering commitment to innovation and dedication to delivering exceptional results. By constantly pushing the boundaries of drilling technology, they have earned the trust and loyalty of clients worldwide.Moving forward, Bta Drilling plans to continue investing in research and development to further advance their drilling technologies. They aim to collaborate with industry experts and partners to drive innovation and tackle the challenges faced by the drilling industry head-on.In conclusion, Bta Drilling has made significant strides in revolutionizing the drilling industry with their cutting-edge technologies. Through their dedication to innovation, commitment to safety, and focus on sustainable practices, the company has positioned itself as a leader in the market. As Bta Drilling looks towards the future, the industry can expect even more groundbreaking solutions that will redefine the way drilling operations are carried out.

Discover the Latest Deep Hole Machine Tools for Industrial Applications

Deep Hole Machine Tools is a leading manufacturer of advanced deep hole drilling machines and tools, catering to a wide range of industries including aerospace, automotive, defense, and oil & gas. With a strong focus on precision, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses worldwide.The company offers a diverse portfolio of deep hole drilling solutions, including gun drilling machines, BTA drilling machines, and ejector drilling machines. These machines are designed to meet the complex and demanding requirements of deep hole drilling, providing high accuracy, efficiency, and reliability in the production process.Deep Hole Machine Tools has a rich history of technological innovation and continuous improvement, leveraging cutting-edge engineering and manufacturing techniques to develop advanced solutions for its customers. The company's R&D team is comprised of industry experts and engineers who are dedicated to pushing the boundaries of deep hole drilling technology, staying ahead of market trends and anticipating the evolving needs of customers.In addition to its extensive product range, Deep Hole Machine Tools also offers custom engineering and consulting services, collaborating closely with clients to understand their specific requirements and provide tailored solutions that meet their unique challenges. This customer-centric approach has earned the company a strong reputation for excellence and reliability in the industry.With a global presence, Deep Hole Machine Tools has established a network of distributors and service centers in key regions around the world, ensuring timely support and assistance for its customers. This commitment to customer service, combined with the company's technical expertise, has positioned Deep Hole Machine Tools as a preferred partner for businesses seeking high-quality deep hole drilling solutions.In recent news, Deep Hole Machine Tools has announced the launch of its latest innovation, the XYZ-5000 series deep hole drilling machine. Featuring state-of-the-art technology and performance enhancements, the XYZ-5000 series is designed to deliver superior accuracy, speed, and versatility in deep hole drilling applications. With a focus on user-friendly operation and advanced control capabilities, the new machine is expected to set new standards in the industry and provide customers with a competitive edge in their operations."We are thrilled to introduce the XYZ-5000 series deep hole drilling machine to the market," said the CEO of Deep Hole Machine Tools. "This machine represents the culmination of our extensive R&D efforts and our commitment to delivering cutting-edge solutions to our customers. We believe that the XYZ-5000 series will empower businesses to achieve new levels of productivity and precision in their deep hole drilling processes."The XYZ-5000 series deep hole drilling machine is equipped with advanced features such as a high-speed drilling spindle, linear motor technology, and intelligent automation capabilities. These innovations enable the machine to achieve faster cycle times, higher drilling depths, and improved tool life, making it suitable for a wide range of applications in various industries.To support the launch of the XYZ-5000 series, Deep Hole Machine Tools is offering comprehensive training programs and technical support services for its customers, ensuring a seamless integration and optimal utilization of the new machine. The company is also providing customization options and retrofitting services to meet specific customer requirements and enhance the capabilities of existing deep hole drilling equipment.As Deep Hole Machine Tools continues to drive innovation and excellence in deep hole drilling technology, the company remains committed to its core values of quality, integrity, and customer satisfaction. With its latest product offering and unwavering dedication to customer success, Deep Hole Machine Tools is poised to solidify its position as a leader in the global deep hole drilling market.

High-Quality Deep Hole Drilling Services for Your Industrial Needs

Deep hole drilling services are at the forefront of innovation in the manufacturing industry, and the team at {} is leading the way with their cutting-edge technology and precision engineering. With a strong focus on customer satisfaction and quality results, {} has built a reputation as a top provider of deep hole drilling services.Deep hole drilling is a specialized process that involves drilling holes with a depth-to-diameter ratio of more than 10:1. This process is commonly used in the manufacturing of components for industries such as aerospace, defense, automotive, and medical. The ability to drill deep holes with high precision and accuracy is essential for the production of complex and critical parts, and {} has positioned themselves as an industry leader in this highly specialized field.{} has a diverse range of deep hole drilling capabilities, including gun drilling, BTA drilling, and ejector drilling. These different methods allow the team to provide solutions for a wide variety of materials and part geometries. Whether the project is for a small batch of prototypes or a large-scale production run, {} has the expertise and equipment to deliver superior results.One of the key advantages of working with {} is their state-of-the-art equipment and facilities. The company's manufacturing facility is equipped with the latest CNC machinery and tooling, allowing for the highest levels of precision and repeatability. Additionally, {} invests in ongoing research and development to stay at the forefront of technological advancements in deep hole drilling. This commitment to innovation ensures that customers receive the best possible solutions for their deep hole drilling needs.In addition to their technical capabilities, {} places a strong emphasis on customer service and satisfaction. The team works closely with each client to understand their specific requirements and design customized solutions to meet their needs. With a focus on clear communication, project management, and quality control, {} ensures that every project is completed to the highest standards. This customer-centric approach has earned {} a loyal and satisfied customer base, further solidifying their position as a leader in the industry.Furthermore, {} is committed to upholding the highest standards of quality and precision. The company holds several industry certifications and adheres to strict quality control processes to ensure that every part meets or exceeds customer expectations. Whether it's tight tolerances, challenging materials, or complex geometries, {} has the expertise and experience to deliver exceptional results.In conclusion, {} is a premier provider of deep hole drilling services, with a reputation for technical excellence, customer satisfaction, and quality results. With their advanced technology, experienced team, and customer-centric approach, {} continues to set the standard for deep hole drilling in the manufacturing industry. Whether it's for aerospace, defense, automotive, medical, or any other industry, customers can rely on {} to deliver the precision and performance they need for their most critical components.

High-Quality Cylinder Honing Machine for CNC Machining Applications

CNC Cylinder Honing Machine Revolutionizing Cylinder Honing TechnologyThe manufacturing industry is constantly evolving, and companies are always looking for new and innovative ways to improve their processes. One company at the forefront of this evolution is {Company name removed}, a leading manufacturer of industrial machinery and equipment. {Company name removed} has recently introduced a groundbreaking new product - the CNC Cylinder Honing Machine, which is set to revolutionize the cylinder honing process.Cylinder honing is a critical process in the manufacturing of engines, hydraulic cylinders, and other precision components. It involves the removal of material from the inner surface of the cylinder to create a precise and smooth finish. Traditionally, this process was carried out manually, which was time-consuming and required highly skilled operators. However, advancements in technology have led to the development of CNC Cylinder Honing Machines, which automate and streamline the honing process.The {Company name removed}'s CNC Cylinder Honing Machine is a state-of-the-art piece of equipment that offers unparalleled precision and efficiency. It is equipped with advanced CNC controls and precision honing tools, allowing for precise control over the honing process. The machine can accommodate a wide range of cylinder sizes and shapes, making it incredibly versatile and suitable for a variety of applications.One of the key features of the CNC Cylinder Honing Machine is its ability to perform complex honing operations with minimal operator intervention. This not only increases productivity but also ensures consistent and high-quality results. Additionally, the machine is designed for easy setup and operation, making it accessible to operators of varying skill levels.In addition to its advanced technology, the {Company name removed}'s CNC Cylinder Honing Machine is built to the highest standards of quality and durability. It is constructed from high-quality materials and components, and undergoes rigorous testing to ensure reliability and performance. This commitment to quality is a hallmark of {Company name removed}'s products, and it is evident in the CNC Cylinder Honing Machine.{Company name removed} has a long-standing reputation for excellence in the manufacturing industry. The company was founded with a vision to provide innovative and high-quality machinery to meet the evolving needs of manufacturers across the globe. Over the years, {Company name removed} has stayed true to this vision, and has become a trusted partner to countless businesses in the automotive, aerospace, energy, and other industries.The introduction of the CNC Cylinder Honing Machine is a testament to {Company name removed}'s commitment to innovation and excellence. This new product is set to disrupt the cylinder honing market and set a new standard for precision and efficiency. By leveraging cutting-edge technology and engineering expertise, {Company name removed} continues to push the boundaries of what is possible in the manufacturing industry.In conclusion, the {Company name removed}'s CNC Cylinder Honing Machine represents a significant advancement in cylinder honing technology. With its advanced features, precision, and reliability, this groundbreaking new product is poised to revolutionize the way cylinder honing is done. As {Company name removed} continues to lead the way in the manufacturing industry, the CNC Cylinder Honing Machine stands as a shining example of the company's commitment to innovation and excellence.

Ultimate Guide to Deep Hole Drilling with CNC Technology

Recently, the deep hole drilling CNC technology has been making waves in the manufacturing industry, with many companies recognizing its potential to revolutionize their production processes. One such company that is at the forefront of this technology is [company name].[Company name] has been a leading player in the manufacturing industry for many years, specializing in the production of high-precision components for various sectors, including automotive, aerospace, and medical. With a commitment to innovation and excellence, the company has always been on the lookout for cutting-edge technologies that can enhance its manufacturing capabilities.One such technology that [company name] has recently invested in is deep hole drilling CNC. This advanced machining process allows for the precise and efficient drilling of deep holes in various materials, including metals and alloys. The technology is particularly well-suited for applications that require high aspect ratio holes, tight tolerances, and superior surface finishes.With the acquisition of the deep hole drilling CNC technology, [company name] aims to further enhance its ability to deliver complex and high-quality components to its customers. By leveraging this advanced machining process, the company can tackle challenging projects that were previously deemed difficult or even impossible. This includes the production of intricate fuel injection components for the automotive industry, high-precision hydraulic cylinders for the aerospace sector, and custom-designed medical implants for the healthcare field.The deep hole drilling CNC technology offers several advantages that align with [company name]'s commitment to excellence. Firstly, it enables the company to achieve superior accuracy and repeatability, ensuring that each component meets the most stringent quality standards. Secondly, the technology allows for faster cycle times, leading to improved productivity and shorter lead times for customers. Additionally, the ability to maintain tight tolerances and excellent surface finishes is crucial for many of [company name]'s applications, and the deep hole drilling CNC technology delivers on these fronts.Moreover, by integrating this advanced machining process into its production line, [company name] can minimize the need for secondary operations, such as honing or reaming, which are typically required to achieve the desired hole quality. This not only streamlines the manufacturing process but also reduces costs and lead times for the company and its customers.Furthermore, the deep hole drilling CNC technology offers [company name] the flexibility to work with a wide range of materials, from stainless steel and titanium to aluminum and exotic alloys. This versatility is essential for the diverse requirements of [company name]'s customer base and enables the company to expand its market reach.In addition to the technological benefits, [company name] has also made significant investments in training its workforce to master the intricacies of deep hole drilling CNC. Through comprehensive training programs and hands-on experience, the company's machinists and engineers have honed their skills to maximize the potential of this cutting-edge technology. This commitment to skill development underscores [company name]'s dedication to staying ahead of the curve in the rapidly evolving manufacturing landscape.As [company name] continues to integrate deep hole drilling CNC into its operations, the company anticipates a positive impact on its competitiveness and ability to take on challenging projects. By leveraging the capabilities of this advanced machining process, [company name] is poised to elevate its position as a key player in the manufacturing industry, offering innovative solutions to meet the evolving needs of its customers.In conclusion, the adoption of deep hole drilling CNC technology marks a significant milestone for [company name], reflecting its unwavering commitment to excellence, innovation, and customer satisfaction. With this advanced machining process in its arsenal, [company name] is well-prepared to tackle complex projects with unparalleled precision and efficiency, solidifying its position as a leading force in the manufacturing industry.

High Precision Six-Coordinate Deep Hole Drilling and Boring Machine

Six-Coordinate CNC Deep Hole Drilling and Boring Machine Sets New Standard in Precision ManufacturingIn today’s highly competitive manufacturing industry, the demand for high-precision machinery has never been greater. Companies are constantly seeking innovative solutions to enhance their production processes and maintain a leading edge in the market. The advent of advanced technology has revolutionized the manufacturing landscape, and companies are turning to state-of-the-art machinery to meet the increasingly stringent requirements of their customers. One such breakthrough in precision manufacturing is the Six-Coordinate CNC Deep Hole Drilling and Boring Machine, which has emerged as a game-changer in the industry.This cutting-edge machine, designed and developed by a global leader in precision machinery manufacturing, has set a new benchmark for accuracy, reliability, and efficiency. With its six-coordinate CNC capability, the machine offers unparalleled precision in deep hole drilling and boring operations, making it an ideal choice for a wide range of industries, including aerospace, automotive, and defense. The machine is designed to meet the complex machining demands of modern-day manufacturing, delivering superior performance and exceptional results.The six-coordinate CNC capability of the machine enables it to accurately and efficiently drill and bore deep holes with a high degree of precision. This advanced technology allows for intricate and complex machining tasks to be completed with the utmost accuracy and consistency, ensuring that the final products meet the most exacting requirements. The machine’s innovative design and state-of-the-art control system provide seamless integration of different machining operations, resulting in a significant reduction in production time and costs.In addition to its exceptional precision, the Six-Coordinate CNC Deep Hole Drilling and Boring Machine is also equipped with advanced features that enhance its performance and versatility. The machine’s high-speed spindle and cutting-edge tooling technology enable it to achieve superior surface finishes and tight tolerances, even in the most challenging materials. Furthermore, its robust construction and sophisticated coolant system ensure stable and reliable operation, even during prolonged machining cycles.With a focus on user-friendly operation and maintenance, the machine is designed for easy setup and programming, allowing operators to quickly adapt to new machining tasks and minimize downtime. Its intuitive control interface and comprehensive monitoring system provide real-time feedback on machining parameters, allowing operators to make informed adjustments and optimize performance. Moreover, the machine’s modular design and customizable options make it adaptable to specific production requirements, ensuring maximum efficiency and flexibility in diverse manufacturing environments.The introduction of the Six-Coordinate CNC Deep Hole Drilling and Boring Machine represents a significant advancement in precision manufacturing technology, offering companies a competitive edge in today’s dynamic market. With its exceptional capabilities, the machine presents new possibilities for the production of complex and high-precision components, driving innovation and excellence in various industries. By investing in this cutting-edge machinery, companies can elevate their manufacturing capabilities and meet the evolving demands of the global market, positioning themselves as leaders in precision engineering and production.As a leading provider of precision machinery, the company remains committed to pushing the boundaries of technology and engineering excellence, delivering innovative solutions that empower manufacturers to achieve the highest standards of quality and performance. With a focus on continuous research and development, the company is dedicated to advancing the capabilities of its machinery, ensuring that customers have access to the latest and most advanced solutions for their production needs.In conclusion, the Six-Coordinate CNC Deep Hole Drilling and Boring Machine represents a transformative leap in precision manufacturing, offering an unprecedented level of accuracy, reliability, and efficiency. Its advanced technology and versatile capabilities make it a crucial asset for companies seeking to excel in today’s competitive market, providing them with the means to produce superior-quality components and stay ahead of the curve. As the industry continues to evolve, this innovative machine is set to redefine the standards of precision manufacturing, driving new possibilities and opportunities for growth.

New Technology to Revolutionize Home Appliances

[Company Name], a leading technology company, has unveiled its latest innovation in the form of a revolutionary machine that is set to transform the way people view home maintenance. The [Product Name], as it is called, is designed to meet the growing need for advanced, user-friendly home maintenance solutions.The [Product Name] is a state-of-the-art machine that combines cutting-edge technology with simplicity and ease of use. It is equipped with a range of features that are designed to make home maintenance tasks faster, easier, and more efficient. From cleaning to repairing and everything in between, the [Product Name] is set to become an essential tool for every household.One of the most innovative features of the [Product Name] is its ability to perform multiple tasks with just a single touch. This means that users can switch between different functions, such as vacuuming, mopping, and dusting, without the need for multiple machines. This not only saves time and effort but also reduces clutter and the need for separate tools, making it an ideal solution for modern homes.In addition to its versatility, the [Product Name] is also equipped with advanced sensors and AI technology, allowing it to adapt to different surfaces and environments. This ensures that the machine can effectively clean and maintain a variety of surfaces, from hardwood floors to carpets, without the need for manual adjustments.Moreover, the [Product Name] is designed with user convenience in mind. It can be controlled remotely via a smartphone app, allowing users to schedule cleaning tasks, monitor the machine's progress, and receive maintenance reminders. This makes it easy to keep the home in top condition, even when users are away.To ensure that the [Product Name] is not only efficient but also safe for use, [Company Name] has implemented a range of safety features. These include collision sensors to prevent the machine from bumping into furniture or other obstructions, as well as a comprehensive set of safety certifications to guarantee its reliability and durability.The [Product Name] is not only designed for individual homeowners but also for commercial and industrial use. With its powerful performance and wide range of applications, it is suitable for various settings, including offices, hotels, and retail spaces. This makes it a versatile and cost-effective solution for businesses looking to optimize their cleaning and maintenance operations.Commenting on the launch of the [Product Name], [Company Name] CEO [Name] expressed his excitement about the potential impact of the new machine. He stated, "We are proud to introduce the [Product Name] to the market, as it represents the culmination of years of research and development. We believe that it will redefine the way people approach home maintenance, bringing convenience, efficiency, and effectiveness to every household."The [Product Name] is expected to hit the market in the coming months, with pre-orders already available on the [Company Name] website. With its advanced features, seamless operation, and wide range of applications, it is poised to become a game-changer in the home maintenance industry. As technology continues to evolve, the [Product Name] is a prime example of how innovation can improve the way people live and work.