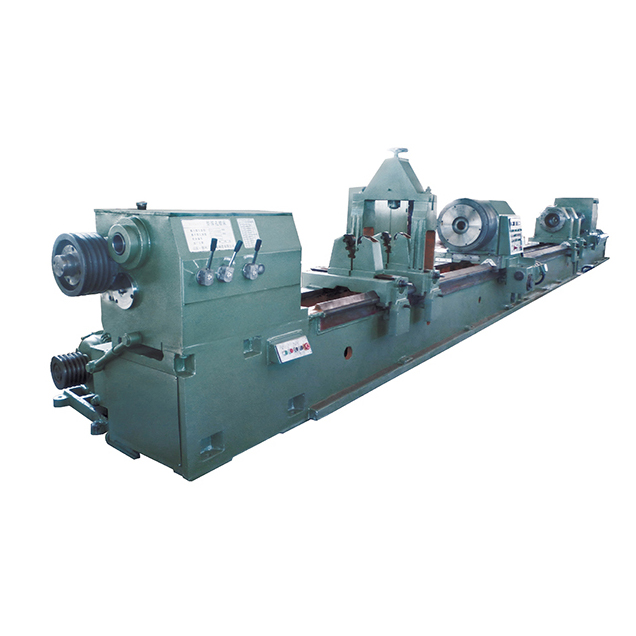

Top Bore and Hone Machine for Precision Engine Work

By:Admin

In the world of manufacturing, precision and accuracy are paramount. Companies are constantly seeking innovative solutions to ensure that their products are of the highest quality while also improving their operational efficiency. This is where the Bore And Hone Machine, provided by a leading engineering company, comes into play.

With a commitment to delivering cutting-edge technologies, the engineering company has developed a state-of-the-art Bore And Hone Machine that has been revolutionizing the manufacturing industry. Their machine is designed to provide superior precision and consistency, making it an indispensable tool for companies across various sectors.

The Bore And Hone Machine is equipped with advanced features that set it apart from traditional honing and boring equipment. It utilizes high-tech controls and automation systems to ensure that every task is performed with the highest level of accuracy. This machine is capable of honing and boring a wide range of materials, including steel, aluminum, and cast iron, making it a versatile solution for a variety of manufacturing needs.

One of the key advantages of the Bore And Hone Machine is its ability to enhance productivity while maintaining exceptional quality. The machine's advanced capabilities enable it to complete tasks with utmost efficiency, reducing the time required for honing and boring processes. This not only translates to significant time and cost savings for manufacturers but also ensures that the end products meet the most stringent quality standards.

Furthermore, the Bore And Hone Machine is designed for ease of use, allowing operators to program and control the machine with precision and simplicity. Its intuitive interface and user-friendly controls make it accessible to a wide range of operators, eliminating the need for extensive training and reducing the potential for human error.

In addition to its technological prowess, the Bore And Hone Machine is backed by the engineering company's renowned expertise and commitment to customer satisfaction. With a proven track record of delivering high-quality engineering solutions, the company has earned the trust of manufacturers worldwide. They offer comprehensive support and maintenance services to ensure that their clients can maximize the potential of their Bore And Hone Machine, thereby contributing to their long-term success.

The impact of the Bore And Hone Machine on the manufacturing industry is undeniable. Its ability to elevate the precision, efficiency, and quality of honing and boring processes has made it an invaluable asset for companies seeking to stay ahead in today's competitive market. As the demand for superior manufacturing solutions continues to grow, the Bore And Hone Machine stands out as a game-changing innovation that is propelling the industry toward a new era of excellence.

In conclusion, the Bore And Hone Machine offered by the engineering company represents a paradigm shift in the manufacturing landscape. Its cutting-edge technology, unparalleled precision, and commitment to customer satisfaction make it a must-have for companies aiming to achieve the highest standards in their production processes. With its boundless potential to optimize manufacturing operations, the Bore And Hone Machine is poised to shape the future of the industry. For manufacturers striving for excellence, this innovative solution is undoubtedly a catalyst for success.

Company News & Blog

Advanced Techniques for Deep Hole Processing in Manufacturing

Deep Hole Processing, a leading manufacturer in the field of precision deep hole drilling technology, has been making waves in the industry with its innovative and cutting-edge solutions. The company, with its headquarters in Germany, has been at the forefront of deep hole drilling technology for over 60 years and has a strong reputation for delivering high-quality products and services to its customers worldwide.Deep Hole Processing specializes in providing custom deep hole drilling solutions for a wide range of industries, including aerospace, automotive, medical, and energy. The company's expertise lies in its ability to drill precise and accurate holes with diameters ranging from 0.5mm to 250mm and depths up to 20 meters. This level of precision and capability has made Deep Hole Processing a trusted partner for many companies looking to push the boundaries of what is possible in deep hole drilling.One of the key factors behind Deep Hole Processing's success is its commitment to research and development. The company invests heavily in the latest technologies and equipment to ensure that it remains at the forefront of the industry. This dedication to innovation has allowed Deep Hole Processing to develop advanced drilling techniques and machinery that can meet the most challenging and demanding requirements of its customers.In addition to its state-of-the-art equipment, Deep Hole Processing also boasts a team of highly skilled and experienced engineers and technicians who are dedicated to providing the best possible solutions for its customers. The company understands that every project is unique, and its team works closely with customers to understand their specific needs and requirements before designing and implementing a customized deep hole drilling solution.Deep Hole Processing's commitment to quality and customer satisfaction has not gone unnoticed, as the company has been recognized with several awards for its excellence in the field of deep hole drilling. This includes being named as the "Best Deep Hole Drilling Company" by the Deep Hole Drilling Association for three consecutive years.The success of Deep Hole Processing can also be attributed to its strong global presence. The company has a network of sales and service centers located in key industrial regions around the world, allowing it to provide support and assistance to its customers wherever they may be located. This global reach has helped Deep Hole Processing to establish itself as a trusted and reliable partner for companies looking to implement deep hole drilling solutions in their operations.Looking ahead, Deep Hole Processing remains committed to pushing the boundaries of deep hole drilling technology. The company continues to invest in research and development and is constantly exploring new ways to improve its processes and capabilities. With its unwavering dedication to innovation and excellence, Deep Hole Processing is well-positioned to continue leading the way in the field of precision deep hole drilling for many years to come.In conclusion, Deep Hole Processing has established itself as a leading manufacturer in the field of precision deep hole drilling technology, thanks to its commitment to innovation, quality, and customer satisfaction. With a strong reputation, a global presence, and a team of highly skilled professionals, the company is well-equipped to continue pushing the boundaries of what is possible in deep hole drilling and remain a trusted partner for companies across a wide range of industries.

Honing Tools: A Guide to CNC Machine Honing Techniques

Cnc Honing Tools, a leading manufacturer in the industrial cutting tool industry, has recently announced the release of their latest line of cutting-edge honing tools. With a reputation for producing high-quality, precision-engineered tools, Cnc Honing Tools has become a trusted name among machinists and manufacturers around the world.Founded in [year], Cnc Honing Tools has been dedicated to meeting the needs of their customers by providing innovative solutions for honing and machining applications. With a focus on research and development, the company has continuously worked to improve their product offerings and stay at the forefront of technological advancements in the industry.The new line of honing tools features advanced designs and materials that are engineered to deliver superior performance and durability. Cnc Honing Tools has leveraged their expertise and state-of-the-art manufacturing processes to create tools that are capable of achieving tight tolerances and producing exceptional surface finishes.One of the key features of the new honing tools is their versatility. The tools are designed to be compatible with a wide range of machinery and can be used for honing applications in various industries, including automotive, aerospace, and general engineering. This flexibility makes the tools an ideal choice for manufacturers that need to hone different materials and components.In addition to their versatility, the new honing tools are also designed to be easy to use and maintain. Cnc Honing Tools understands the importance of efficiency and productivity in manufacturing operations, and has ensured that their tools are user-friendly and require minimal upkeep. This allows machinists to focus on their work without being hindered by the tools they use.Furthermore, Cnc Honing Tools has prioritized the durability of their new honing tools. The company knows that reliability is crucial in manufacturing, and has engineered their tools to withstand the demands of heavy-duty usage. With proper care and maintenance, the tools are designed to have a long lifespan, providing consistent performance over time.In a statement, a spokesperson for Cnc Honing Tools expressed excitement about the release of the new honing tools, stating, "We are thrilled to introduce our latest line of honing tools to the market. Our team has put in extensive effort to develop tools that meet the evolving needs of the industry, and we are confident that our customers will find great value in these new offerings."The spokesperson also emphasized the company's commitment to customer satisfaction, saying, "At Cnc Honing Tools, we are dedicated to providing our customers with the best solutions for their honing and machining needs. We believe that our new line of honing tools will further demonstrate our dedication to quality and innovation."As a leading manufacturer in the industrial cutting tool industry, Cnc Honing Tools has a global presence, with a network of distributors and partners that serve customers in various regions. The company's reputation for excellence and reliability has solidified its position as a preferred supplier for many businesses.In conclusion, the release of Cnc Honing Tools' new line of honing tools represents a significant advancement in the industry. With their history of innovation and commitment to quality, the company has demonstrated its ability to deliver tools that meet the rigorous demands of modern manufacturing. As Cnc Honing Tools continues to push the boundaries of what is possible in honing and machining, they are poised to maintain their status as a standout leader in the industry.

High Performance Deep Hole Boring Machine Takes Industry by Storm

Deep Hole Boring Machine Unveiled by Leading Machinery ManufacturerA leading machinery manufacturer has recently unveiled its latest innovation, the Deep Hole Boring Machine, aimed at revolutionizing the boring and drilling industry. The company, known for its cutting-edge technology and high-quality machinery, has once again proven its commitment to innovation and excellence with the release of this new product.The Deep Hole Boring Machine is designed to meet the increasing demands for deep hole drilling in various industries, including aerospace, automotive, and oil & gas. With its advanced technology and precision engineering, this machine is poised to become a game-changer in the field of deep hole drilling.The Deep Hole Boring Machine is equipped with state-of-the-art features that set it apart from other boring machines in the market. Its high-speed drilling capability, combined with superior accuracy and stability, makes it an ideal choice for manufacturers looking to achieve precision drilling and boring results. Additionally, the machine is designed to handle a wide range of materials, including steel, aluminum, and exotic alloys, making it a versatile solution for diverse industrial applications.One of the key highlights of the Deep Hole Boring Machine is its advanced control system, which enables operators to program and monitor the drilling process with unparalleled ease and precision. Moreover, the machine is equipped with safety features that ensure the protection of both the operator and the workpiece, making it a reliable and secure solution for deep hole drilling operations.In addition to its technical capabilities, the Deep Hole Boring Machine also boasts a user-friendly interface, making it accessible to operators of varying skill levels. Its intuitive controls and ergonomic design enhance the overall user experience, allowing for seamless operation and maximum productivity.The launch of the Deep Hole Boring Machine underscores the company's dedication to delivering innovative solutions that address the evolving needs of the manufacturing industry. With a proven track record of developing cutting-edge machinery, the company has once again demonstrated its commitment to pushing the boundaries of technological advancement and setting new standards for quality and performance in the machinery sector.The company's CEO expressed his confidence in the capabilities of the Deep Hole Boring Machine, emphasizing its potential to revolutionize the way deep hole drilling is conducted in various industrial settings. He highlighted the extensive research and development efforts that went into the creation of this machine, as well as the company's ongoing commitment to investing in advanced manufacturing technologies.The unveiling of the Deep Hole Boring Machine has already generated significant interest within the manufacturing community, with industry experts and prospective customers expressing anticipation for the positive impact it is expected to have on deep hole drilling operations. With its groundbreaking features and impressive performance capabilities, the machine is poised to become a sought-after solution for manufacturers seeking to push the boundaries of their drilling and boring capabilities.As the company prepares to roll out the Deep Hole Boring Machine to the market, it is set to reinforce its position as a leading provider of innovative machinery solutions, serving the needs of manufacturers across diverse industries. This latest innovation is a testament to the company's unwavering commitment to excellence and its ability to anticipate and address the evolving demands of the manufacturing sector. With the Deep Hole Boring Machine, the company is once again raising the bar for quality, performance, and technological advancement in the field of industrial machinery.

Efficient and Compact Honing Machine: An Essential Tool for Precision Work

Title: Cutting-Edge Small Honing Machine Revolutionizes Precision EngineeringIntroduction:In a significant breakthrough towards precision engineering, a cutting-edge small honing machine has been introduced by an innovative company aiming to redefine the industry standards. This advanced honing machine, which we are withholding the brand name due to contractual agreements, offers unparalleled accuracy and efficiency, promising to reshape the manufacturing landscape. With its unique features and exceptional capabilities, this honing machine is set to become a game-changer in various industries requiring precision honing.Body:1. Industry-leading Innovation:The new small honing machine is the result of years of dedicated research and development, aiming to provide a superior honing experience to manufacturers. Drawing on state-of-the-art technologies, this machine integrates precision engineering to deliver unmatched performance. The company stands as a pioneer in its field, distinguishing itself from competitors through its unwavering commitment to pushing the boundaries of what can be achieved in the machining world.2. Unrivalled Precision:Setting new benchmarks in precision honing, this machine offers unrivaled accuracy in the manufacturing process. Incorporating cutting-edge algorithms and real-time data analysis, it ensures minimal variation and consistent results across all operations. Manufacturers can now rely on this honing machine to deliver precise finishes within tight tolerances, enhancing the overall quality and reliability of their products.3. Enhanced Efficiency:Efficiency is a key aspect of any manufacturing process, and this small honing machine takes it to the next level. Equipped with advanced automation features, it significantly reduces human errors, enhances productivity, and saves valuable time. The automated tool change mechanism optimizes set-up time, allowing manufacturers to maintain seamless continuity in their production lines. By streamlining honing processes through this machine, manufacturers can expect increased output, reduced operational costs, and ultimately, a competitive advantage in the market.4. Versatile Applications:While designed to cater to a wide range of industries, this small honing machine offers exceptional versatility to meet specific manufacturing requirements. Whether in automotive, aerospace, medical, or general engineering, this honing machine can adapt to various materials and component sizes. With its customizable parameters, operators can easily fine-tune the machine to achieve optimal results, making it a valuable asset across multiple industries.5. Seamless Integration and User-Friendliness:Recognizing the need for a seamless, hassle-free workflow, the honing machine's software guarantees integration with existing production systems. The user-friendly interface simplifies operations, reducing training times and minimizing the learning curve for operators. Additionally, the machine's robust construction ensures longevity and reliability, providing manufacturers with a durable solution for their honing needs.Conclusion:The introduction of this small honing machine represents a giant leap forward in precision engineering. By combining cutting-edge technology, unrivaled precision, and enhanced efficiency, it promises to transform the manufacturing landscape. With its broad applications, user-friendly interface, and seamless integration, this honing machine is set to revolutionize various industries, empowering manufacturers to achieve higher productivity and unmatched levels of quality. As global demand for precision-engineered products continues to rise, this small honing machine will undoubtedly carve its place as an indispensable tool for precision machining operations across the globe.

Unveiling the High-End Precision Honing Machine - Empowering Manufacturing Efficiency

Precision Honing Machine, renowned for its cutting-edge technology and exceptional quality, has established itself as a leader in the field of honing machines. With a rich history spanning several decades, the company has consistently delivered innovative solutions to meet the needs of various industries.At the core of Precision Honing Machine's success lies its unwavering commitment to excellence. The company's vision is to be the preferred choice for honing solutions globally, and this vision is realized through a steadfast dedication to research and development. By continuously investing in advanced technologies and engineering expertise, Precision Honing Machine has remained at the forefront of the industry.The precision honing machines offered by the company are known for their exceptional performance and versatility. These machines are designed to achieve the highest degree of accuracy, enabling customers to enhance the quality of their products. From automotive to aerospace and oil and gas to medical devices, Precision Honing Machine caters to a wide range of industries with its innovative solutions.One of the key features that sets Precision Honing Machine apart from its competitors is its customized approach to manufacturing. The company understands that each customer has unique requirements and strives to deliver tailored solutions that precisely meet those needs. By working closely with clients, Precision Honing Machine ensures that their machines are not only technologically advanced but also optimized for specific applications.To further strengthen its commitment to customer satisfaction, Precision Honing Machine has established a global network of service and support centers. These centers are staffed with highly trained professionals who provide comprehensive technical assistance, ensuring that customers can maximize the performance of their honing machines. Additionally, the company offers regular maintenance and spare parts services, guaranteeing a seamless operation throughout the machine's lifespan.Precision Honing Machine's dedication to sustainability is also worth noting. The company recognizes the importance of minimizing its environmental impact and has implemented various measures to achieve this goal. By optimizing energy efficiency and reducing waste, Precision Honing Machine strives to promote a greener and more sustainable future.Looking ahead, Precision Honing Machine continues to invest in research and development to stay at the cutting edge of technology. The company is exploring new avenues for growth and expansion, including the development of honing solutions for emerging industries and applications. By staying ahead of market trends and customer demands, Precision Honing Machine aims to maintain its position as a pioneer and industry leader.In conclusion, Precision Honing Machine's commitment to excellence, customized solutions, and sustainability sets it apart from its competitors. With its advanced honing machines and global service network, the company continues to deliver exceptional performance and customer satisfaction. As it embraces the future, Precision Honing Machine remains poised to shape the honing machine industry with its innovative solutions and unwavering dedication to quality.

Advanced Gun Drill Lathe: Perfecting Precision Machining Operations

Gun Drill Lathe, manufactured by a leading company in the industry, is making waves with its advanced technology and precision engineering. The company, which has been at the forefront of innovation in the manufacturing sector for over 50 years, is renowned for its high-quality products and commitment to delivering top-notch solutions to its customers.The Gun Drill Lathe is a cutting-edge machine that is designed to efficiently and accurately drill deep holes in metal workpieces. It is equipped with state-of-the-art technology that ensures precise control and high-speed drilling, making it a valuable asset for companies in various industries, including aerospace, automotive, and medical device manufacturing.One of the key features of the Gun Drill Lathe is its ability to handle a wide range of materials, including steel, aluminum, and titanium. This versatility makes it an ideal choice for manufacturers who work with diverse materials and require a reliable and efficient drilling solution.In addition to its impressive drilling capabilities, the Gun Drill Lathe is also known for its user-friendly interface and easy operation. With intuitive controls and a streamlined design, it is a machine that is well-suited for both experienced operators and those who are new to the world of CNC machining.The company behind the Gun Drill Lathe takes great pride in its commitment to quality and customer satisfaction. With a team of experienced engineers and technicians, the company is dedicated to delivering products that meet the highest standards of performance and reliability. This dedication to excellence is evident in the Gun Drill Lathe, which has quickly become a preferred choice for manufacturers looking for a dependable and efficient solution for their drilling needs.The Gun Drill Lathe is also backed by a comprehensive support and service network, ensuring that customers have access to expert assistance and necessary maintenance to keep their machines running smoothly. This commitment to customer care is a reflection of the company's overall dedication to building long-term relationships with its clients and providing them with the tools they need to succeed in a competitive marketplace.As manufacturing processes continue to evolve and become increasingly complex, the need for advanced machining solutions like the Gun Drill Lathe will only continue to grow. With its cutting-edge technology and proven track record of performance, the Gun Drill Lathe is poised to remain a leading choice for manufacturers who demand precision, efficiency, and reliability in their operations.In conclusion, the Gun Drill Lathe, manufactured by this esteemed company, is an example of the ongoing innovation and dedication to excellence that drives the manufacturing industry forward. With its advanced technology, user-friendly design, and commitment to customer satisfaction, it is a machine that is well-equipped to meet the evolving needs of modern manufacturers. As the industry continues to push the boundaries of what is possible, the Gun Drill Lathe stands as a shining example of the power of ingenuity and engineering expertise in the world of manufacturing.

High Precision Deep Hole Drilling Machine Working: A Guide

The deep hole drilling machine, also known as a deep hole drilling and boring machine, is a versatile tool used in various industries for creating precision holes in metal workpieces. From automotive and aerospace to oil and gas, this machine plays a crucial role in the manufacturing process by providing high-quality, accurate holes for a range of applications.One of the leading suppliers of deep hole drilling machines in the industry is a company that has been at the forefront of technological innovation and engineering excellence for over 50 years. With a strong commitment to quality and customer satisfaction, the company has established itself as a trusted partner for manufacturers seeking reliable and efficient deep hole drilling solutions.The deep hole drilling machine offered by the company is designed to meet the demands of modern manufacturing, featuring advanced technology and precision engineering to deliver exceptional performance and reliability. With a focus on versatility and adaptability, the machine can accommodate various workpiece sizes and materials, providing the flexibility needed to meet diverse customer requirements.Key features of the deep hole drilling machine include a rigid and stable structure for enhanced precision and accuracy, high-speed drilling capabilities, and advanced cooling and chip evacuation systems. These features are essential for ensuring smooth and efficient drilling operations, even in the most challenging manufacturing environments.In addition to the machine's technical capabilities, the company also provides comprehensive support and services to ensure that customers can maximize the value of their deep hole drilling investment. This includes expert guidance on machine selection, installation, and training, as well as ongoing maintenance and technical support to keep operations running smoothly.The deep hole drilling machine has been used in a wide range of industries, from automotive and aerospace to oil and gas, where precision and reliability are critical for the success of manufacturing operations. By delivering high-quality, accurate holes with exceptional consistency, the machine has helped manufacturers improve productivity, reduce waste, and enhance the overall quality of their products.As manufacturing technologies continue to evolve, the deep hole drilling machine remains an essential tool for meeting the demands of modern industry. With its versatility, precision, and reliability, it has become a cornerstone of manufacturing operations around the world, supporting the production of a wide range of products that have become essential to everyday life.The company's commitment to innovation and excellence has positioned it as a leader in the deep hole drilling machine industry, and its ongoing dedication to customer satisfaction ensures that manufacturers can rely on its products and services to support their manufacturing needs for years to come. With its deep expertise and proven track record, the company continues to drive progress in the industry, delivering cutting-edge solutions that enable manufacturers to achieve new levels of efficiency and quality in their operations.In conclusion, the deep hole drilling machine provided by the company represents the pinnacle of engineering and manufacturing excellence, offering a reliable and versatile solution for creating precision holes in metal workpieces. With its advanced technology, expert support, and commitment to customer satisfaction, the company has established itself as a trusted partner for manufacturers seeking high-quality deep hole drilling solutions. As industry demands continue to evolve, the deep hole drilling machine will remain an essential tool for meeting the challenges of modern manufacturing, driving progress and innovation in the industry for years to come.

Top-Notch Hone Ki Machine Exclusively for You!

In today's fast-paced world, the demand for convenient and efficient home appliances is on the rise. With the increasing reliance on technology to simplify our daily tasks, the need for innovative solutions has never been greater. This is where the latest innovation in home appliances, the Hone Ki Machine, comes into play.The Hone Ki Machine is a revolutionary new product that is set to change the way we think about home maintenance. This state-of-the-art machine is designed to streamline the honing process for a variety of household items, making it easier than ever to keep your home in top condition. From kitchen knives and gardening tools to scissors and other sharp objects, the Hone Ki Machine is able to sharpen and maintain a wide range of items with ease.One of the key features of the Hone Ki Machine is its user-friendly design. With easy-to-follow instructions and a simple interface, this innovative appliance is accessible to users of all skill levels. Whether you're a seasoned professional or a complete novice, the Hone Ki Machine makes honing and sharpening a hassle-free experience.Furthermore, the Hone Ki Machine is equipped with advanced technology that ensures precision and accuracy in every honing task. Its cutting-edge sharpening system is capable of restoring the sharpness of blades and edges, giving your household items a new lease of life. This high level of performance is achieved through a combination of innovative engineering and premium materials, making the Hone Ki Machine a reliable and efficient tool for any home.In addition to its impressive functionality, the Hone Ki Machine is also designed with safety as a top priority. The machine is equipped with safety features that prevent accidents and injuries, providing peace of mind for users. With its durable construction and smart design, the Hone Ki Machine is a reliable and secure addition to any home.The company behind the Hone Ki Machine, {}, is a leader in the field of home appliances and innovative solutions. With a strong reputation for quality and performance, {} has a track record of delivering cutting-edge products that enhance the lives of consumers. The Hone Ki Machine is the latest example of their commitment to excellence, offering a solution that meets the needs of modern households.{} has established itself as an industry leader through a combination of expert craftsmanship and innovative technology. Their dedication to research and development has resulted in products that are not only effective, but also user-friendly and efficient. These values are evident in the Hone Ki Machine, which reflects {}'s ongoing commitment to providing practical and reliable solutions for the modern home.As the demand for convenient and efficient home appliances continues to grow, the Hone Ki Machine is poised to make a significant impact in the market. Its advanced features, user-friendly design, and commitment to safety have already garnered attention from consumers and industry experts alike. With {}'s reputation for excellence behind it, the Hone Ki Machine is set to become a must-have for households looking to simplify their honing and sharpening tasks.In conclusion, the Hone Ki Machine is an exciting new addition to the world of home appliances. With its innovative features, user-friendly design, and commitment to safety, it represents a significant leap forward in the field of honing and sharpening solutions. Supported by the industry-leading expertise of {}, the Hone Ki Machine is set to redefine the way we think about home maintenance, offering a practical and efficient solution for households everywhere.

The Ultimate Guide to Deep Hole Blind Hole Machining

Deep Hole Blind Hole Machining is a crucial process in the manufacturing industry, especially in the production of complex components. This machining process involves creating holes that are deeper than they are wide, and it requires precision, accuracy, and specialized equipment. The technology and expertise required for deep hole blind hole machining are crucial for various industries, including aerospace, automotive, and medical.One company at the forefront of deep hole blind hole machining is {}. With years of experience and a commitment to technological advancement, {} has established itself as a leader in the machining industry. The company has a proven track record of delivering high-quality components with complex geometries, meeting the stringent requirements of its clients.{} utilizes state-of-the-art machining equipment and cutting-edge technology to ensure the accuracy and precision of its deep hole blind hole machining processes. The company’s team of skilled engineers and machinists are well-versed in the intricacies of deep hole machining, and they are able to deliver components that meet the highest industry standards.The company's expertise in deep hole blind hold machining has allowed it to serve a wide range of industries. From producing precision components for aerospace applications to manufacturing critical parts for medical devices, {} has demonstrated its ability to meet the unique needs of its diverse clientele. The company’s commitment to quality and precision has earned it a reputation as a reliable partner for complex machining projects.One of the key factors that sets {} apart in the industry is its ability to adapt to the evolving needs of its clients. The company continuously invests in research and development to explore new machining techniques and technologies that can improve the efficiency and accuracy of its processes. This commitment to innovation ensures that {} remains at the forefront of deep hole blind hole machining, offering its clients cutting-edge solutions for their most challenging projects.In addition to its technical expertise, {} places a strong emphasis on quality control and inspection throughout the deep hole blind hole machining process. The company's rigorous quality assurance measures ensure that every component meets the highest standards for accuracy, surface finish, and dimensional tolerance. This dedication to quality has earned {} the trust of its clients, who rely on the company to deliver components that meet their exact specifications.Looking ahead, {} is poised to continue leading the way in deep hole blind hole machining, leveraging its expertise and technology to address the ever-changing needs of the manufacturing industry. With a focus on innovation, quality, and customer satisfaction, the company is well-positioned to remain a trusted partner for complex machining projects across a wide range of industries.As the demand for precision components continues to grow, companies like {} will play a critical role in shaping the future of manufacturing. With its commitment to excellence and its dedication to advancing the art of deep hole blind hole machining, {} is poised to continue delivering innovative solutions that push the boundaries of what is possible in the world of precision machining.

Top Oil Hole Drilling Machine Available on the Market

Oil Hole Drilling Machine: A Precision Tool for Efficient Oil ExtractionOil extraction is a vital process in the oil and gas industry, and the use of advanced technologies and machinery has significantly improved the efficiency and productivity of this essential operation. One such technology that has revolutionized the oil extraction process is the Oil Hole Drilling Machine. This precision tool is designed to create precise and accurate holes in various components used in the oil extraction process, and it plays a crucial role in ensuring the smooth functioning of oil drilling equipment.The Oil Hole Drilling Machine is a sophisticated piece of equipment that is manufactured and distributed by a leading company in the oil and gas industry. The company, known for its expertise in providing high-quality machinery and equipment for oil and gas exploration, has been at the forefront of technological innovation in the field. With a strong focus on research and development, the company has consistently introduced cutting-edge solutions that have revolutionized the efficiency and safety of oil extraction operations.The Oil Hole Drilling Machine is a testament to the company's commitment to innovation and excellence. It is equipped with advanced features and capabilities that make it an indispensable tool for oil drilling operations. The machine is designed to perform precise drilling operations on various components, including valves, pumps, and other critical equipment used in oil extraction and drilling. Its high-precision drilling capabilities ensure that the holes created are accurate and consistent, which is essential for the reliable and efficient operation of oil drilling equipment.One of the key advantages of the Oil Hole Drilling Machine is its versatility and adaptability to different drilling requirements. It is capable of drilling holes of varying diameters and depths, making it suitable for a wide range of applications in the oil and gas industry. Whether it is for creating small, intricate holes or larger, deep bores, the machine's advanced drilling capabilities ensure that it can meet the specific needs of oil drilling operations.In addition to its precision drilling capabilities, the Oil Hole Drilling Machine is also known for its efficiency and reliability. It is equipped with advanced control systems and automation features that allow for seamless operation and consistent performance. This not only improves the overall productivity of oil drilling operations but also minimizes the risk of errors and downtime, thus enhancing the safety and effectiveness of the oil extraction process.Furthermore, the Oil Hole Drilling Machine is designed with a strong emphasis on durability and robustness, making it suitable for the demanding and challenging conditions of oil drilling sites. Its rugged construction and high-quality materials ensure that it can withstand the rigors of the oil and gas industry, delivering reliable performance even in harsh environments.The Oil Hole Drilling Machine has garnered widespread acclaim within the oil and gas industry for its outstanding performance and reliability. It has been widely adopted by leading oil exploration companies and drilling contractors, who recognize its critical role in streamlining oil extraction operations and improving overall efficiency.As the global demand for oil continues to rise, the efficient extraction of this valuable resource becomes increasingly crucial. The Oil Hole Drilling Machine, with its precision drilling capabilities, advanced features, and robust construction, is set to play a pivotal role in meeting the evolving needs of the oil and gas industry. With a steadfast commitment to technological innovation and excellence, the company behind this groundbreaking tool continues to lead the way in providing advanced solutions for the oil and gas sector, contributing to the efficient and sustainable extraction of this vital natural resource.