Top Drilling Company Delivers Quality Services for Various Industries

By:Admin

The new technology, which the company has been developing for the past few years, is a game-changer in the field of drilling. It promises to significantly increase efficiency and productivity while minimizing the environmental impact of drilling operations.

BTA Drilling Company has always been at the forefront of innovation in the industry. With a strong focus on research and development, the company has continually strived to push the boundaries of what is possible in drilling technology. This latest breakthrough is a testament to the company's commitment to driving positive change in the industry.

The new technology is a result of years of research and development, combined with the expertise of BTA Drilling Company's team of engineers and scientists. It is designed to address some of the most pressing challenges in the industry, such as the need for more sustainable and environmentally friendly drilling methods.

One of the key features of the new technology is its ability to significantly reduce the environmental impact of drilling operations. By incorporating advanced filtration and recycling systems, the technology is able to minimize the amount of waste generated during drilling. This is a major step forward in making drilling operations more sustainable and in line with environmental regulations.

In addition to its environmental benefits, the new technology also promises to increase efficiency and productivity in drilling operations. With its advanced automation and monitoring systems, the technology streamlines the drilling process, allowing for faster and more accurate operations. This ultimately results in cost savings for drilling companies and increased output.

BTA Drilling Company's new technology has already garnered significant interest from industry leaders and experts. Many are touting it as a potential game-changer in the industry, with the potential to set new standards for drilling operations.

"We are thrilled to introduce this groundbreaking new technology to the industry," said the CEO of BTA Drilling Company. "We believe that it has the potential to revolutionize the way drilling operations are carried out, paving the way for a more sustainable and efficient future for the industry."

The introduction of this new technology comes at a critical time for the oil and gas industry, as companies are increasingly under pressure to adopt more sustainable and environmentally friendly practices. With the new technology from BTA Drilling Company, companies now have a viable solution to meet these demands without compromising on productivity and efficiency.

The company is currently in the process of deploying the new technology in various drilling operations around the world. Initial feedback from these deployments has been overwhelmingly positive, with companies reporting significant improvements in efficiency and sustainability.

As the industry eagerly awaits the widespread adoption of this groundbreaking new technology, BTA Drilling Company continues to lead the way in driving innovation and positive change in the industry. With its forward-thinking approach and commitment to excellence, the company is well-positioned to continue making a significant impact in the field of drilling.

Company News & Blog

Bta Drilling: The Latest Developments in the Drilling Industry

Bta Drilling Revolutionizing the Drilling Industry with Cutting-Edge TechnologiesInnovative drilling solutions have always been at the forefront of the oil and gas industry, where companies constantly strive to achieve faster, more efficient, and cost-effective drilling operations. Bta Drilling, a renowned player in the field, has made a significant impact with its cutting-edge technologies and state-of-the-art equipment that have revolutionized the drilling industry.With decades of experience, Bta Drilling has established itself as a leader in the market, providing a wide range of drilling services for various industries. By combining their expertise with the latest technological advancements, the company has consistently set new benchmarks, enabling their clients to achieve unprecedented levels of productivity and success.Utilizing advanced drilling systems and tools, Bta Drilling has significantly improved drilling speed and efficiency. Their innovative technologies are designed to optimize drilling performance, reduce downtime, and minimize environmental impact. The company's team of engineers and scientists work tirelessly to develop and enhance their drilling systems, ensuring that they stay at the forefront of the industry.One of the key technologies that sets Bta Drilling apart is their proprietary drilling fluid. This unique solution provides excellent lubrication and cooling properties, ensuring smooth drilling operations and increased tool life. The fluid's advanced composition also minimizes waste and reduces environmental impact, aligning with Bta Drilling's commitment to sustainable practices.Additionally, Bta Drilling has pioneered the use of advanced data analytics and machine learning algorithms to optimize drilling operations. By analyzing vast amounts of drilling data in real-time, their algorithms can predict potential issues before they occur, allowing for proactive maintenance and minimizing costly downtime. These data-driven insights also help streamline drilling processes, further improving overall efficiency.Another area where Bta Drilling has made significant advancements is in directional drilling. Their state-of-the-art tools and techniques enable precise wellbore placement, allowing for increased extraction rates and reservoir access. This cutting-edge technology has proven to be a game-changer for oil and gas companies looking to maximize production and profitability.Furthermore, Bta Drilling's commitment to safety is unwavering. Their advanced drilling systems prioritize worker safety and minimize risks associated with drilling operations. Rigorous training programs and adherence to international safety standards ensure that Bta Drilling maintains an impeccable safety record, giving their clients peace of mind and confidence in their services.Bta Drilling's success can be attributed to their unwavering commitment to innovation and dedication to delivering exceptional results. By constantly pushing the boundaries of drilling technology, they have earned the trust and loyalty of clients worldwide.Moving forward, Bta Drilling plans to continue investing in research and development to further advance their drilling technologies. They aim to collaborate with industry experts and partners to drive innovation and tackle the challenges faced by the drilling industry head-on.In conclusion, Bta Drilling has made significant strides in revolutionizing the drilling industry with their cutting-edge technologies. Through their dedication to innovation, commitment to safety, and focus on sustainable practices, the company has positioned itself as a leader in the market. As Bta Drilling looks towards the future, the industry can expect even more groundbreaking solutions that will redefine the way drilling operations are carried out.

Powerful Pistol Drill Machine for Precision Drilling Operations

Pistol Drill Machine: A Game-Changer in Construction EquipmentThe construction industry has seen tremendous advancements in technology in recent years, with new and innovative machines being introduced to make the work more efficient and streamlined. One such machine that has been making waves in the industry is the Pistol Drill Machine, a state-of-the-art drilling equipment that has revolutionized the way construction projects are carried out.Developed by a leading construction equipment company, the Pistol Drill Machine is designed to provide unmatched performance and reliability for a wide range of drilling applications. Its advanced features and cutting-edge technology have set a new standard for drilling equipment, making it a game-changer in the construction industry.The Pistol Drill Machine boasts a powerful and robust design, capable of handling the toughest drilling jobs with ease. Whether it's drilling through concrete, wood, or metal, this machine delivers exceptional results, thanks to its high-performance motor and precision-engineered drilling components.One of the key highlights of the Pistol Drill Machine is its ergonomic and user-friendly design. The machine is engineered to provide maximum comfort and control for the operator, reducing fatigue and improving productivity on the job site. Its lightweight yet durable construction makes it easy to handle, while the intuitive controls and adjustable settings make it adaptable to different drilling requirements.Furthermore, the Pistol Drill Machine is equipped with advanced safety features to ensure the well-being of the operator and those around the job site. From the integrated safety mechanisms to the durable housing and protective shields, every aspect of the machine is designed to minimize the risk of accidents and ensure a safe working environment.In addition to its performance and safety features, the Pistol Drill Machine is also equipped with smart technology that enhances its functionality and efficiency. The machine is equipped with a digital display and programmable settings, allowing for precise control and customization of drilling parameters. This level of automation not only simplifies the operation but also improves the accuracy and consistency of drilling results.The company behind the Pistol Drill Machine takes pride in its commitment to quality and innovation. With a solid reputation in the construction equipment industry, the company has continuously pushed the boundaries of what's possible in terms of performance, reliability, and user experience. Its team of experienced engineers and designers are dedicated to developing cutting-edge solutions that meet the evolving needs of the construction industry.Moreover, the company's support and service network ensure that customers get the most out of their investment in the Pistol Drill Machine. From comprehensive training programs to responsive technical support, the company goes the extra mile to ensure that its customers are well-equipped to maximize the potential of the machine.The Pistol Drill Machine has already made a significant impact in the construction industry, earning accolades from contractors, engineers, and operators. Its versatility, durability, and advanced features have made it a sought-after drilling equipment for a wide range of applications, further solidifying its reputation as a game-changer in the industry.Looking ahead, the company remains committed to pushing the boundaries of innovation and setting new benchmarks for performance and reliability in construction equipment. With the Pistol Drill Machine leading the charge, it's clear that the future of drilling technology is in capable hands.

Powerful Engine Line Hone Machine for Precision Machining

Engine Line Hone Machine: Revolutionizing Engine ManufacturingIn the ever-evolving world of automotive engineering, precision and efficiency are paramount. With the increasing demand for high-performance engines, manufacturers are constantly seeking innovative solutions to ensure top-notch quality and optimal functionality. One such solution is the Engine Line Hone Machine, a cutting-edge technology that has revolutionized engine manufacturing processes.The Engine Line Hone Machine is a vital component in the production of high-quality engines. It is designed to precisely hone the bearing bores in engine blocks, thereby ensuring a perfect fit for the crankshaft bearings. This crucial process significantly contributes to the overall performance and longevity of the engine. By utilizing the latest advancements in engineering and technology, the Engine Line Hone Machine has become an indispensable tool for manufacturers seeking to achieve unparalleled precision and efficiency in their engine production processes.One company at the forefront of this technological innovation is {}. With a longstanding reputation for excellence in the automotive industry, {} has consistently pushed the boundaries of engineering and manufacturing. Committed to delivering top-tier solutions to its clients, the company has embraced the Engine Line Hone Machine as an integral part of its production line. By incorporating this cutting-edge technology, {} has been able to streamline its engine manufacturing processes, resulting in higher precision, increased productivity, and superior quality.The Engine Line Hone Machine offered by {} stands out for its exceptional performance and reliability. Equipped with advanced features and state-of-the-art capabilities, this machine is capable of achieving precise and consistent results, meeting the stringent requirements of modern engine manufacturing. Its user-friendly interface and intuitive controls make it easy to operate, while its robust construction ensures durability and longevity. With a focus on delivering unparalleled accuracy and efficiency, {} has established itself as a leading provider of Engine Line Hone Machines, catering to the diverse needs of automotive manufacturers worldwide.In addition to its cutting-edge technology, {} places a strong emphasis on customer support and satisfaction. The company's team of skilled engineers and technical experts are dedicated to providing comprehensive assistance, from installation and training to ongoing maintenance and support. By offering a holistic approach to customer service, {} ensures that its clients are able to maximize the potential of the Engine Line Hone Machine, ultimately leading to a seamless and successful integration into their production processes.The impact of the Engine Line Hone Machine on engine manufacturing has been significant. By enabling manufacturers to achieve unparalleled precision and consistency, this technology has led to the production of engines that are not only high-performing but also durable and reliable. With the ability to hone bearing bores with utmost accuracy, the Engine Line Hone Machine has become a cornerstone of modern engine production, playing a pivotal role in the quest for superior quality and performance.Looking ahead, the future of engine manufacturing is poised for further advancements, and the Engine Line Hone Machine will undoubtedly continue to play a central role in this evolution. As automotive technology continues to progress, the demand for engines with uncompromising quality and precision will only increase. It is clear that the Engine Line Hone Machine will remain an indispensable tool for manufacturers seeking to stay ahead of the curve and deliver engines that meet the highest standards of excellence.In conclusion, the Engine Line Hone Machine has reshaped the landscape of engine manufacturing, empowering companies like {} to elevate their production processes and deliver exceptional results. With its cutting-edge technology, unwavering commitment to quality, and comprehensive customer support, {} has proven itself as a driving force in the automotive industry. As the demand for high-performance engines continues to rise, the Engine Line Hone Machine will undoubtedly remain a cornerstone of innovation and precision in engine manufacturing.

High Precision Cylinder Honing Machine for Cnc Applications

The CNC Cylinder Honing Machine is a cutting-edge piece of equipment that has revolutionized the cylinder honing process. This machine, produced by a leading manufacturer in the industry, has set a new industry standard for precision and performance.With the ability to hone a wide range of cylinder sizes and materials, this CNC Cylinder Honing Machine offers unparalleled flexibility and versatility. Its advanced technology and innovative design allow for precise control of the honing process, resulting in superior surface finish and tight tolerances.The company behind this state-of-the-art machine is a global leader in manufacturing precision machinery for various industries. With a long history of innovation and a commitment to excellence, the company has earned a reputation for delivering high-quality products that meet the demanding needs of its customers.In addition to the CNC Cylinder Honing Machine, the company offers a comprehensive range of honing machines, abrasive tools, and honing oils. This diverse product line allows customers to find the perfect solution for their specific honing needs, whether they are working with small engine cylinders or large industrial components.The CNC Cylinder Honing Machine is designed to provide maximum productivity and efficiency. Its user-friendly interface and intuitive controls make it easy to set up and operate, allowing operators to quickly hone cylinders with minimal training. This results in significant time and cost savings, making it an ideal choice for the modern machine shop.Furthermore, this honing machine is equipped with advanced features that ensure optimal performance and reliability. Its robust construction and high-quality components guarantee long-term durability and consistent results, even in the most demanding production environments.The company also offers comprehensive technical support and training programs to ensure that customers get the most out of their CNC Cylinder Honing Machine. With a global network of service centers and knowledgeable experts, customers can rely on the company for ongoing support and assistance.In addition to its technical expertise, the company is committed to sustainability and environmental responsibility. The CNC Cylinder Honing Machine is designed to minimize waste and energy consumption, while its advanced filtration system ensures a clean and safe working environment.With its cutting-edge technology, exceptional performance, and commitment to customer satisfaction, the CNC Cylinder Honing Machine from this leading manufacturer is a game-changer for the honing industry. Its precision, reliability, and ease of use make it the top choice for machine shops and manufacturers around the world.In conclusion, the CNC Cylinder Honing Machine, produced by this renowned company, demonstrates a perfect blend of innovation, quality, and performance. With its unparalleled precision and productivity, this machine has set a new standard for cylinder honing, and it is sure to be a valuable asset for any business looking to achieve superior results in their honing operations.

Advanced CNC Honing Machine for Precision Machining

CNC Honing Machine Revolutionizes Precision Machining ProcessesIn today's rapidly evolving manufacturing industry, precision and accuracy are paramount. As the demand for complex and high-quality components continues to rise, the need for advanced machining technology becomes increasingly important. This is where the CNC honing machine comes into play, revolutionizing the way precision parts are manufactured.The CNC honing machine, developed by a leading machinery manufacturer, is a cutting-edge piece of equipment that has quickly become a game-changer in the world of precision machining. This state-of-the-art machine is designed to perform honing operations with unparalleled precision and efficiency, making it an indispensable tool for industries such as automotive, aerospace, hydraulics, and more.One of the key features of this advanced CNC honing machine is its ability to perform complex machining operations with ease, thanks to its high level of automation and computerized control. This allows for perfect repeatability and consistency in the honing process, resulting in superior quality finished parts.The company behind this innovative CNC honing machine has a long-standing reputation for delivering top-quality machinery solutions to the manufacturing industry. With a focus on innovation and cutting-edge technology, the company has consistently pushed the boundaries of what is possible in precision machining, and the CNC honing machine is no exception.With a commitment to providing reliable and efficient machinery, the company has invested heavily in research and development to ensure that its CNC honing machine remains at the forefront of precision machining technology. This dedication to innovation has resulted in a machine that is not only highly precise but also versatile, capable of handling a wide range of honing applications with ease.The CNC honing machine is equipped with advanced features that set it apart from traditional honing machines. These include high-speed spindles, precision tooling, and advanced monitoring and control systems that allow for real-time adjustments and optimization during the honing process. This level of sophistication ensures that the machine can deliver precise and consistent results, even when working with the most challenging materials and geometries.In addition to its advanced technological capabilities, the CNC honing machine is also designed with user-friendly features that make it easy to operate and maintain. From intuitive touchscreen controls to automated tool changing and maintenance functions, the machine is engineered to streamline the honing process and minimize downtime, ultimately increasing productivity and efficiency for the end user.The impact of this advanced CNC honing machine is far-reaching, with manufacturers across various industries reaping the benefits of its precision and reliability. From producing high-performance engine components for the automotive sector to manufacturing critical aerospace parts with strict tolerances, the machine has proven to be a versatile and essential asset for any precision machining operation.Looking ahead, the company behind the CNC honing machine is committed to further advancing its technology and capabilities to meet the evolving needs of the manufacturing industry. With a focus on continuous improvement and customer satisfaction, the company aims to remain at the forefront of precision machining technology, providing innovative solutions that empower manufacturers to achieve new levels of precision and quality in their production processes.As the demand for high-quality, precision components continues to grow, the CNC honing machine stands ready to play a pivotal role in shaping the future of precision machining. With its advanced technology, reliability, and versatility, this cutting-edge machine is set to revolutionize the way manufacturers approach honing operations, setting new standards for precision and efficiency in the manufacturing industry.

Everything You Need to Know About Honing Services

CNC Honing, a leading provider of honing and precision machining services, has announced the expansion of its capabilities with the acquisition of state-of-the-art machinery and technology. The company has always been dedicated to providing high-quality, precision-engineered products to a wide range of industries, and this investment in new equipment demonstrates their commitment to staying at the forefront of the industry.With a history of over 30 years in the precision machining industry, CNC Honing has built a reputation for delivering exceptional products with superior precision and accuracy. The company specializes in honing, a machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive stone against it along a controlled path. This process results in improved geometric form, surface texture, and tight tolerances, making it ideal for a variety of applications across industries such as automotive, aerospace, medical, and hydraulics.The recent acquisition of advanced CNC honing machines represents a significant step forward for the company. These machines feature cutting-edge technology that allows for even greater precision and accuracy in the honing process. By investing in the latest equipment, CNC Honing is able to offer its customers even more advanced capabilities, further solidifying its position as a leader in the industry.The company's commitment to quality and precision is evident in every aspect of its operations. From the initial design and engineering phase through to the final production and inspection of parts, CNC Honing's stringent quality control measures ensure that every product meets the highest standards. This dedication to excellence has earned the company a loyal customer base and has contributed to its continued success and growth over the years.In addition to its focus on precision machining, CNC Honing also places a strong emphasis on innovation and continuous improvement. The company's team of skilled engineers and technicians is constantly exploring new techniques and technologies to enhance the efficiency and effectiveness of its processes. This commitment to innovation has allowed CNC Honing to stay ahead of the curve and deliver cutting-edge solutions to its customers.With the expansion of its capabilities through the acquisition of new CNC honing machines, CNC Honing is well-positioned to meet the evolving needs of its customers across a diverse range of industries. Whether it's producing complex components for the aerospace industry or precision hydraulic cylinders for industrial applications, the company's advanced honing capabilities enable it to deliver products that meet the most demanding specifications.As CNC Honing continues to invest in the latest technologies and expand its capabilities, it remains committed to upholding its core values of quality, precision, and customer satisfaction. The company's dedication to excellence, combined with its relentless pursuit of innovation, ensures that it will remain a trusted partner for precision machining solutions for years to come.In conclusion, CNC Honing's recent investment in advanced CNC honing machines represents a significant milestone for the company and further solidifies its position as a leader in the precision machining industry. With its unwavering commitment to quality and continuous improvement, CNC Honing is well-prepared to meet the evolving needs of its customers and continue delivering exceptional products and services.

High Precision Honing Machine for CNC Applications: Everything You Need to Know

CNC Honing Machine: Revolutionizing Precision MachiningIn today’s fast-paced manufacturing industry, precision and efficiency are key factors in producing high-quality products. Meeting the demands of precision machining, [Company Name] is proud to introduce its latest innovation, the CNC Honing Machine. This cutting-edge technology is set to revolutionize the way precision parts are manufactured, setting a new standard for excellence in the industry.With over [X] years of experience in the manufacturing sector, [Company Name] has established itself as a leader in providing innovative solutions for precision machining. The introduction of the CNC Honing Machine is a testament to the company's commitment to advancing the capabilities of modern manufacturing processes.What sets the CNC Honing Machine apart from traditional honing machines is its state-of-the-art computer numerical control (CNC) technology. This advanced system allows for precise control and automation of the honing process, resulting in superior accuracy and consistency in the finished product. The CNC technology also enables the machine to execute complex honing operations with ease, reducing the need for manual intervention and minimizing the margin of error.In addition to its cutting-edge CNC technology, the CNC Honing Machine is equipped with a range of features designed to optimize efficiency and productivity. The machine’s high-speed honing capability allows for faster cycle times, increasing throughput and reducing lead times for production. This is especially beneficial for industries with high-volume production requirements, where time is of the essence.Furthermore, the CNC Honing Machine offers versatility in honing a wide range of materials, from soft metals to hard alloys. Its adaptive honing process is designed to deliver consistent results across different workpieces, making it a valuable asset for manufacturers with diverse machining needs.One of the key advantages of the CNC Honing Machine is its ability to achieve precise surface finishes with tight tolerances. This is essential in industries such as aerospace, automotive, and medical, where components require extraordinary precision to meet stringent quality standards. The machine’s capability to hone complex geometries and achieve superior surface finishes makes it an invaluable tool for manufacturers seeking to elevate the quality of their products.Moreover, [Company Name] takes pride in its commitment to sustainability and environmental responsibility. The CNC Honing Machine is designed with energy-efficient features that contribute to reducing power consumption and minimizing environmental impact. By integrating sustainable practices into its manufacturing processes, [Company Name] demonstrates its dedication to creating a greener and more sustainable future for the industry.As part of its dedication to customer satisfaction, [Company Name] provides comprehensive training and support for the operation and maintenance of the CNC Honing Machine. This ensures that customers are equipped with the knowledge and resources needed to maximize the capabilities of the machine and achieve optimal results in their manufacturing operations.The introduction of the CNC Honing Machine signifies a new era in precision machining, offering manufacturers a powerful tool to elevate the quality and efficiency of their production processes. With its cutting-edge technology, versatility, and commitment to sustainability, the CNC Honing Machine from [Company Name] is poised to set new standards for excellence in the industry. As manufacturing continues to evolve, [Company Name] remains at the forefront of innovation, providing solutions that empower manufacturers to thrive in a competitive global market.

High-Precision Honing Machine for Enhanced Manufacturing Operations

According to recent industry reports, the demand for high-precision honing machines is on the rise, driven by the growing need for advanced manufacturing solutions across various sectors. In response to this trend, {Company Name} has emerged as a leading provider of state-of-the-art honing machines, offering a wide range of advanced solutions to meet the diverse needs of the modern manufacturing industry.{Company Name} is a renowned manufacturer of honing machines, with a strong focus on innovation, precision, and efficiency. The company takes pride in its ability to design and develop cutting-edge honing solutions that are at the forefront of technology, delivering exceptional performance and reliability to its customers.One of the key offerings from {Company Name} is its range of advanced honing machines, which are designed to deliver superior accuracy, consistency, and surface finish. These machines are widely used in the automotive, aerospace, hydraulic, and other precision manufacturing industries, where highly precise bore sizing and finishing are critical to the overall quality and performance of the final products.The honing machines offered by {Company Name} are equipped with advanced features such as high-speed stroking, automatic tool wear compensation, and real-time process monitoring, allowing for efficient and precise honing of a wide range of materials, including steel, cast iron, aluminum, and various alloys. Furthermore, the company’s machines are designed to be highly versatile, with the ability to handle a wide range of bore diameters and lengths, making them an ideal solution for diverse manufacturing applications.In addition to its cutting-edge honing machines, {Company Name} also offers comprehensive technical support and after-sales services to ensure that its customers can maximize the performance and longevity of their honing equipment. The company’s team of highly skilled engineers and technicians are dedicated to providing ongoing support, including installation, training, maintenance, and troubleshooting, to ensure that its customers can achieve optimal results and minimize downtime.Furthermore, {Company Name} is committed to ongoing innovation and R&D efforts, continuously seeking to enhance the performance and capabilities of its honing machines. The company invests heavily in research and development, collaborating with industry leaders and leveraging the latest technological advancements to develop new and improved honing solutions that meet the evolving needs of the manufacturing industry.With a strong reputation for quality, reliability, and innovation, {Company Name} has established itself as a trusted partner for manufacturers seeking high-performance honing machines and related solutions. The company’s commitment to excellence, combined with its customer-centric approach, has earned it a loyal customer base and positioned it as a leader in the honing machine industry.As the demand for high-precision manufacturing solutions continues to grow, {Company Name} is well-positioned to meet the increasing need for advanced honing machines, providing manufacturers with the tools they need to achieve superior quality, consistency, and efficiency in their production processes. With its unwavering dedication to innovation and customer satisfaction, {Company Name} is poised to remain at the forefront of the honing machine industry, driving the future of precision manufacturing.

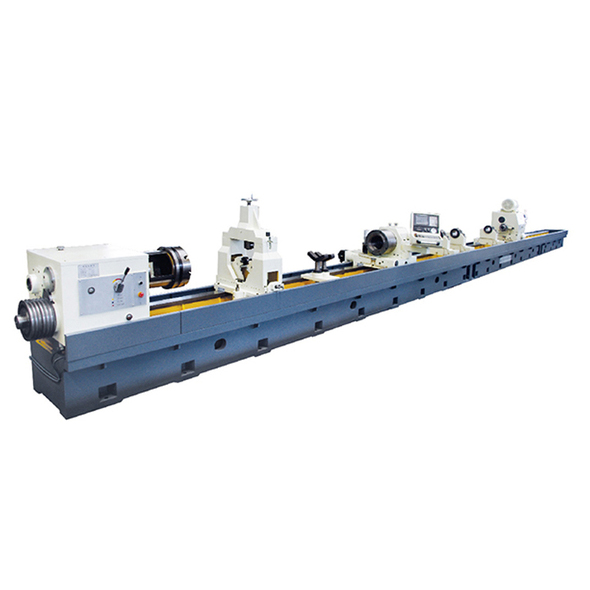

Advanced Four-Axis CNC Deep Hole Drilling Machine Unveiled in Latest News

Title: Advanced Four-Axis CNC Deep Hole Drilling Machine Revolutionizes Industrial ManufacturingIntroduction:In recent breakthrough news, a pioneering Four-Axis CNC Deep Hole Drilling Machine has been unveiled by a cutting-edge industrial machinery company. With its innovative design and state-of-the-art technology, this groundbreaking machine promises to revolutionize the manufacturing industry. Leveraging precision engineering and advanced automation, this deep hole drilling machine offers unparalleled efficiency, accuracy, and versatility for a wide range of industrial applications.1. Enhanced Precision and Accuracy:Utilizing advanced four-axis technology, this new CNC deep hole drilling machine pushes the boundaries of precision machining. The intricate drilling process is executed with exceptional accuracy, ensuring optimal performance in demanding industries such as aerospace, automotive, and energy. The machine utilizes high-precision linear guides and spindle drives, resulting in precise and stable drilling operations. This cutting-edge technology reduces human error, enhancing the overall quality of the finished product.2. Unmatched Efficiency:The integration of intuitive software and automation in this Four-Axis CNC Deep Hole Drilling Machine streamlines the manufacturing process, drastically reducing production time. The machine features a user-friendly interface, allowing operators to easily program and control drilling parameters. The advanced automation capabilities enable constant monitoring and adjustment, minimizing downtime and maximizing productivity. This results in improved manufacturing efficiency and reduced costs for businesses.3. Versatility in Machining Applications:The new four-axis CNC deep hole drilling machine caters to a diverse range of industrial applications, thanks to its adaptable nature. From drilling complex parts to creating shallow holes with high precision, this machine can handle a wide variety of materials, including metal, alloy, and composite materials. Additionally, its four-axis capability ensures the machining of complex parts with intricate geometries, expanding its usefulness across different industries.4. Intelligent Cooling System:The CNC deep hole drilling machine incorporates an intelligent cooling system that helps dissipate heat for prolonged operation. This innovative feature prevents component damage caused by overheating, ensuring extended machine life and reducing maintenance and repair costs. The cooling system also enhances the drilling process by efficiently removing chips and debris, maintaining superior drilling performance throughout the operation.5. Commitment to Quality and Reliability:The company behind the Four-Axis CNC Deep Hole Drilling Machine has built credibility and trust through its commitment to delivering high-quality industrial machinery. With years of industry experience, the company prioritizes stringent quality control measures to ensure that their products meet the highest standards. The machine undergoes rigorous testing to guarantee optimum durability, reliability, and customer satisfaction.6. Positive Industry Implications:The introduction of the Four-Axis CNC Deep Hole Drilling Machine provides a transformative solution for various industries. By improving drilling precision, streamlining processes, and reducing production time, this cutting-edge machine enhances manufacturing capabilities, facilitating technological advancements, and ultimately leading to cost-effective and high-quality end products.Conclusion:The unveiling of the Four-Axis CNC Deep Hole Drilling Machine marks a significant milestone in the manufacturing industry. With its enhanced precision, unbeatable efficiency, and versatility in machining applications, this groundbreaking machine holds tremendous potential to revolutionize industrial manufacturing. By combining advanced technology, automation, and a commitment to quality and reliability, the company behind this innovative machinery is poised to make a significant impact in the market, paving the way for future advancements and driving overall industry growth.

Top Gun Drilling Tools for Precision Machining: A Complete Guide

Gun Drilling Tools, a leading manufacturer of high-quality drilling tools, has announced the release of their latest line of innovative drilling solutions. With a strong focus on quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses in the oil and gas, aerospace, automotive, and medical industries.Founded in 1995, Gun Drilling Tools has continuously invested in research and development to create cutting-edge drilling technologies. The company's state-of-the-art manufacturing facilities and team of experienced engineers enable them to design and produce a wide range of drilling tools, including deep hole drills, gun drills, and BTA drills. Their commitment to excellence has earned them a reputation for delivering high-performance products that meet the demanding requirements of their customers.One of the key highlights of Gun Drilling Tools' latest product line is the introduction of their advanced coating technology. This innovative surface treatment not only enhances the durability and longevity of the drilling tools but also improves their overall performance. The proprietary coating is designed to reduce friction, dissipate heat, and prevent chip buildup, resulting in smoother and more efficient drilling operations.In addition to their cutting-edge technology, Gun Drilling Tools takes pride in their dedication to customer service. The company works closely with their clients to understand their specific drilling needs and challenges, offering customized solutions to meet their requirements. Whether it's developing a new tool design or providing technical support, Gun Drilling Tools is committed to delivering excellent service at every step of the process."We are thrilled to introduce our latest line of drilling tools, which represents our ongoing commitment to innovation and excellence," said the spokesperson for Gun Drilling Tools. "We understand the critical role that drilling plays in our customers' operations, and we are dedicated to providing them with the best tools to achieve their objectives. With our advanced coating technology and focus on customer satisfaction, we are confident that our new products will deliver outstanding results."The new line of drilling tools from Gun Drilling Tools is now available for purchase, and the company is already receiving positive feedback from early adopters. Customers have praised the performance and durability of the tools, highlighting their ability to withstand the rigors of demanding drilling applications. With a strong track record of success and a commitment to continuous improvement, Gun Drilling Tools is well-positioned to remain a leader in the industry.In conclusion, Gun Drilling Tools' latest product line exemplifies the company's dedication to innovation, quality, and customer satisfaction. With their advanced coating technology and customized solutions, they continue to provide businesses in various industries with the tools they need to succeed in their drilling operations. As the industry evolves, Gun Drilling Tools remains at the forefront, delivering cutting-edge solutions that empower their customers to achieve their goals.