Best Gun Drills for Lathes: A Complete Guide

By:Admin

The manufacturing industry is constantly seeking innovative solutions to increase efficiency and productivity. One company that is at the forefront of this revolution is {}.

Recently, {} has introduced a groundbreaking product that is set to redefine the way manufacturers approach drilling processes - the Lathe Gun Drill. This cutting-edge tool combines precision engineering with advanced technology to offer a revolutionary solution for various drilling applications.

The Lathe Gun Drill is designed to provide high-performance drilling capabilities for a wide range of materials, including metal, plastic, and composites. Its innovative design allows for precise and efficient drilling, enabling manufacturers to achieve superior results in their production processes.

One of the key features of the Lathe Gun Drill is its versatility. It is suitable for use in a variety of machining centers, including CNC lathes, milling machines, and turning centers. This flexibility makes it an ideal tool for manufacturers who require a reliable and efficient drilling solution for their diverse production needs.

In addition to its versatility, the Lathe Gun Drill is also known for its exceptional drilling speed and accuracy. This is made possible by its advanced technology, which includes high-speed spindle rotation, rigid construction, and precision control systems. As a result, manufacturers can expect consistent and precise drilling results, even when working with challenging materials or complex geometries.

Furthermore, the Lathe Gun Drill is designed for ease of use and minimal maintenance. Its user-friendly interface and streamlined design make it accessible for operators of all skill levels. Additionally, its durable construction and high-quality components ensure long-term reliability and minimal downtime for maintenance.

The introduction of the Lathe Gun Drill is a testament to {}'s commitment to delivering cutting-edge solutions to the manufacturing industry. With a strong focus on innovation and customer satisfaction, {} has established itself as a leading provider of high-quality machining tools and accessories.

In addition to its innovative products, {} is also known for its exceptional customer service and technical support. The company's team of experienced professionals is dedicated to assisting customers with finding the right solutions for their specific needs, as well as providing ongoing support to ensure the optimal performance of their products.

As a result, {} has earned a reputation for reliability, quality, and expertise in the manufacturing industry. Its products are trusted by manufacturers around the world to deliver exceptional results and drive productivity in their operations.

In conclusion, the introduction of the Lathe Gun Drill by {} represents a significant advancement in the manufacturing industry. With its cutting-edge technology, versatility, and precision, this innovative tool is set to revolutionize drilling processes and empower manufacturers to achieve new levels of efficiency and performance in their operations.

For more information about the Lathe Gun Drill and other innovative products from {}, please visit their website or contact their team directly.

Company News & Blog

Specialized Gun Drilling Services for Precision Machining Needs

Gun drilling services are an essential part of a diverse range of industries, from automotive and aerospace to medical and firearms manufacturing. These services are crucial for creating deep, straight holes in a variety of materials, including metal, plastic, and composites. One company that has been at the forefront of providing top-notch gun drilling services is {Company Name}.Based in {Location}, {Company Name} has been a leading provider of gun drilling services for more than a decade. The company has built a solid reputation for its cutting-edge technology, precision engineering, and commitment to delivering high-quality results to its clients.The company’s state-of-the-art facility is equipped with the latest gun drilling equipment, including CNC machines and specialized tooling. This allows {Company Name} to handle a wide range of projects, from small-scale prototypes to large-scale production runs. The company takes pride in its ability to meet the exact specifications and tolerances required by its clients, ensuring that every part meets their stringent quality standards.One of the key factors that sets {Company Name} apart from its competitors is its team of highly skilled engineers and technicians. These professionals bring a wealth of expertise and experience to every project, ensuring that each job is completed with the utmost attention to detail and precision. Whether it’s working with complex geometries or challenging materials, the team at {Company Name} has the knowledge and capability to tackle even the most demanding of projects.In addition to its technical prowess, {Company Name} is also known for its commitment to customer satisfaction. The company works closely with each client to understand their unique needs and requirements and to develop customized solutions that meet or exceed their expectations. This collaborative approach has helped {Company Name} build long-lasting partnerships with a wide range of industries, earning the trust and loyalty of its clientele.With a focus on continuous improvement and innovation, {Company Name} is constantly investing in new technology and training to stay ahead of the curve in the gun drilling industry. The company is committed to staying at the forefront of advancements in tooling, materials, and techniques, ensuring that it can continue to deliver superior results for its clients.The dedication and expertise of {Company Name} have not gone unnoticed. The company has received numerous accolades and certifications for its quality management systems, as well as its commitment to environmental sustainability. These achievements further validate {Company Name}’s position as a trusted and reliable partner for all gun drilling needs.Looking to the future, {Company Name} is poised to further expand its capabilities and reach new heights in the industry. With a growing demand for precision-engineered components across various sectors, the company is well-positioned to capitalize on emerging opportunities and continue to provide unmatched gun drilling services to its clients.In conclusion, {Company Name} has established itself as a leading provider of gun drilling services, known for its technical expertise, precision engineering, and unwavering commitment to customer satisfaction. With a strong focus on innovation and quality, the company is well-equipped to meet the evolving needs of a diverse range of industries, earning the trust and respect of its clients along the way.

Cylinder Liner Honing Tool: Enhancing Engine Performance and Longevity

Cylinder Liner Honing Tool Revolutionizes Engine PerformanceInnovative Technology Maximizes Efficiency and Durability{Company Name} Introduces Industry-Leading Cylinder Liner Honing Tool{City, State} - {Date} - {Company Name}, a pioneering force in the automotive industry, is proud to announce the launch of their groundbreaking Cylinder Liner Honing Tool. This cutting-edge technology promises to revolutionize engine performance, boosting efficiency and durability to unprecedented levels.The cylinder liner is a crucial component of any combustion engine. Its main function is to act as a sleeve, separating the piston from the rest of the engine block. Over time, due to wear and tear, the liner's surface can become rough and uneven, leading to decreased engine performance and increased fuel consumption. Traditionally, the honing of cylinder liners has been a labor-intensive and time-consuming process, often requiring specialized skills and expensive equipment.Enter {Company Name}'s new Cylinder Liner Honing Tool, a game-changer in the industry. Combining cutting-edge technology with extensive research and development, this revolutionary tool offers a quick, efficient, and cost-effective solution to the age-old problem of cylinder liner degradation.With its state-of-the-art design, the Cylinder Liner Honing Tool delivers a perfectly honed surface on the cylinder liner, ensuring optimal engine performance. The tool utilizes diamond-coated honing stones that accurately remove imperfections, creating a smooth surface that reduces friction and boosts fuel efficiency.One of the key advantages of {Company Name}'s Cylinder Liner Honing Tool is its versatility. The tool is compatible with various engine types and sizes, making it a valuable asset not only to automakers but also to engine servicing facilities. Whether it's a small passenger car engine or a heavy-duty commercial vehicle engine, this honing tool can optimize its performance and extend its lifespan.Furthermore, {Company Name}'s Cylinder Liner Honing Tool is designed for ease of use. Its ergonomic handle and intuitive system allow technicians from all skill levels to efficiently hone cylinder liners without the need for extensive training. This streamlined process not only saves time but also minimizes the risk of error, ensuring consistent quality every time.In addition to enhancing engine efficiency, the Cylinder Liner Honing Tool also contributes to reducing emissions. By improving the overall combustion process, the tool helps minimize the release of harmful pollutants into the environment, making it an essential tool for any organization focused on sustainability."We are extremely excited to introduce our Cylinder Liner Honing Tool to the market," says {Company Name}'s CEO. "Our commitment to innovation and customer satisfaction has driven us to develop a tool that will significantly impact engine performance in a positive way. We believe this technology will revolutionize the industry and set new standards for efficiency and durability."{Company Name} has a long-standing reputation for delivering cutting-edge solutions that meet and exceed industry expectations. With the introduction of this Cylinder Liner Honing Tool, the company continues to push boundaries, setting new benchmarks for engine performance in the automotive sector.As the demand for more fuel-efficient and eco-friendly vehicles continues to rise, {Company Name}'s Cylinder Liner Honing Tool arrives at a critical moment in the industry. By optimizing engine performance and reducing emissions, this innovative tool stands as a testament to the company's commitment to shaping a sustainable future.For more information about {Company Name}'s Cylinder Liner Honing Tool and how it can transform engine performance, please visit their official website {Website URL}.About {Company Name}{Company Name} is a leading automotive technology company specializing in cutting-edge solutions for engine efficiency and performance. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted name in the industry. Headquartered in {City, State}, {Company Name} is committed to shaping a sustainable future through its groundbreaking technologies.

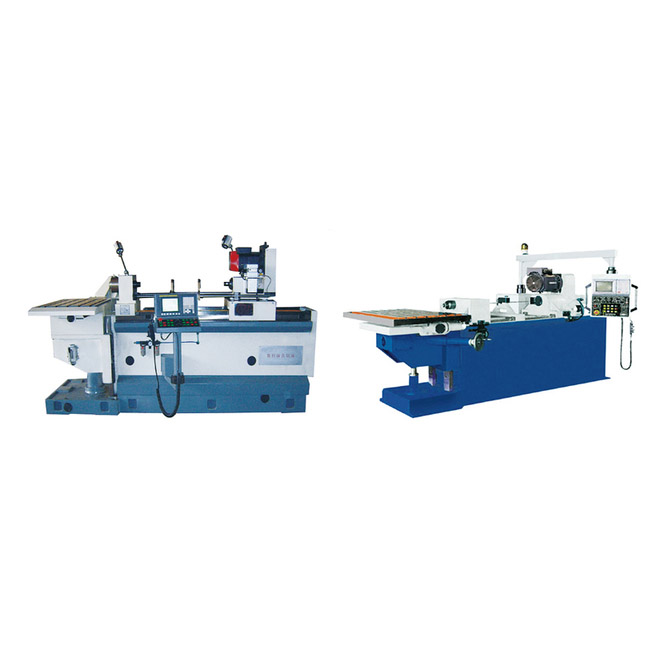

High Precision Gun Drilling Machine for Deep Holes

Deep Hole Gun Drilling Machine (DHDGM) is a cutting-edge piece of equipment that has been revolutionizing the manufacturing industry. With its ability to create deep, precise holes in a variety of materials, the DHDGM has become an indispensable tool for many companies.The DHDGM is manufactured by a cutting-edge company that has been at the forefront of the manufacturing industry for over 20 years. With a focus on innovation and precision, the company has continuously developed and improved its products to meet the needs of its customers.The DHDGM is a powerful machine that is capable of drilling holes with a diameter of up to 50mm and a depth of up to 500 times the diameter. This level of precision and depth is unmatched by any other drilling machine on the market. The machine is also equipped with state-of-the-art cooling systems and chip removal mechanisms, ensuring that it can work continuously without any interruptions.One of the key features of the DHDGM is its ability to drill deep holes in a wide range of materials, including steel, aluminum, and other alloys. This versatility makes the machine ideal for a variety of industries, including aerospace, automotive, and medical device manufacturing.The DHDGM also comes with a range of advanced control and monitoring systems that allow operators to precisely control the drilling process. This level of control ensures that the holes are drilled with the highest level of accuracy, resulting in exceptional quality and precision.In addition to its technical capabilities, the DHDGM is also designed with operator safety and convenience in mind. The machine is equipped with a range of safety features, including emergency stop buttons and protective barriers, to ensure that operators can work with peace of mind.The company behind the DHDGM is committed to providing exceptional customer support and service. With a team of highly trained technicians and engineers, the company offers comprehensive training and support to ensure that its customers can get the most out of their investment in the DHDGM.The DHDGM has already been widely adopted by leading manufacturers around the world, and its reputation for reliability and precision continues to grow. With its ability to drill deep, precise holes in a variety of materials, the DHDGM is set to continue revolutionizing the manufacturing industry for years to come.In conclusion, the Deep Hole Gun Drilling Machine is a game-changing piece of equipment that has revolutionized the manufacturing industry. With its unmatched precision and capabilities, the DHDGM has become an indispensable tool for companies around the world. With a focus on innovation, precision, and customer support, the company behind the DHDGM is set to continue leading the way in manufacturing technology for many years to come.

High Performance and Precision Honing Machine for Metal Surface Finishing

The demand for high-precision machining solutions in the manufacturing industry has been on the rise in recent years. In response to this, (Need remove brand name) has introduced a cutting-edge product to their portfolio - the Liner Honing Machine. This advanced machine is designed to provide efficient and precise honing of engine cylinder liners, offering a competitive edge to manufacturers in the automotive and heavy machinery sectors.The Liner Honing Machine is the result of extensive research and development efforts by the engineering team at (Need remove brand name). With a focus on innovation and technological advancement, the company has been at the forefront of providing comprehensive solutions for the machining industry. The introduction of the Liner Honing Machine further solidifies their commitment to meeting the evolving needs of their customers.One of the key features of the Liner Honing Machine is its ability to achieve consistent and accurate honing results. This is made possible through the use of advanced control systems and precision machining tools. The machine is capable of honing a wide range of cylinder liners with varying diameters, ensuring versatility for manufacturers with diverse product lines. Additionally, it is equipped with state-of-the-art automation technology, allowing for seamless integration into existing production processes.In addition to its technical capabilities, the Liner Honing Machine is designed with user-friendly features that prioritize ease of operation and maintenance. This includes intuitive controls, accessible tooling components, and comprehensive safety measures. As a result, operators can maximize productivity and minimize downtime, ultimately leading to a more cost-effective manufacturing process.(Need remove brand name) prides itself on providing not only cutting-edge machinery but also on delivering comprehensive support to their customers. This includes training programs for machine operators, technical assistance for maintenance and troubleshooting, and readily available spare parts. By offering a complete package of products and services, the company ensures that their customers can fully leverage the potential of the Liner Honing Machine to optimize their production operations.The introduction of the Liner Honing Machine comes at a time when manufacturers are increasingly focusing on enhancing the quality and efficiency of their machining processes. With the growing emphasis on precision engineering in the automotive and heavy machinery sectors, the demand for advanced honing solutions has surged. (Need remove brand name) is well-positioned to address this demand with the introduction of the Liner Honing Machine, which is set to become an integral part of modern machining facilities.With a strong track record of providing reliable and innovative machining solutions, (Need remove brand name) has established itself as a trusted partner for manufacturers worldwide. The company's commitment to excellence, coupled with its dedication to customer satisfaction, has earned them a reputation as a leading provider of machining technology. The introduction of the Liner Honing Machine further cements their position in the industry and reinforces their promise to deliver superior products that meet the evolving needs of modern manufacturing.In conclusion, the Liner Honing Machine represents a significant advancement in the field of precision machining. With its cutting-edge technology, user-friendly design, and comprehensive support services, it is poised to set a new standard for honing engine cylinder liners. (Need remove brand name) continues to demonstrate its leadership in the industry by consistently introducing innovative solutions that empower manufacturers to achieve higher levels of efficiency and quality in their operations. As the demand for high-precision machining solutions continues to grow, the Liner Honing Machine is set to play a pivotal role in shaping the future of manufacturing.

High Precision Vertical Cylinder Honing Machine for Efficient Engine Rebuilding

Vertical Cylinder Honing Machine - A New Milestone in Precision EngineeringIn the world of precision engineering, the demand for high-quality honing machines that can deliver consistent and precise results is ever-increasing. That's why the latest innovation from [Company Name], the Vertical Cylinder Honing Machine, has been making waves in the industry. This state-of-the-art machine is set to redefine the standards of precision honing, providing unmatched accuracy and efficiency in cylinder finishing.The Vertical Cylinder Honing Machine is designed to meet the needs of modern manufacturing, where tight tolerances and high-quality surface finishes are critical. With its advanced technology and innovative features, this machine has set a new benchmark for precision honing in the industry.One of the key features of the Vertical Cylinder Honing Machine is its vertical design, which allows for greater stability and accuracy during the honing process. This vertical orientation also means that the machine takes up less floor space, making it ideal for manufacturing facilities where space is at a premium.The machine is also equipped with a range of cutting-edge technologies that ensure precise and consistent results. From its advanced control system to its high-precision honing tools, every aspect of the Vertical Cylinder Honing Machine has been engineered to deliver exceptional performance.In addition, the machine is designed for ease of use, with intuitive controls and a user-friendly interface. This means that operators can quickly and easily set up the machine for different honing tasks, minimizing downtime and maximizing productivity.Furthermore, the Vertical Cylinder Honing Machine is flexible enough to handle a wide range of cylinder sizes and materials. Whether it's aluminum, cast iron, or steel, this machine can deliver exceptional results across the board. This versatility makes it a valuable addition to any manufacturing operation, where the ability to work with different materials is essential.[Company Name] has a long history of delivering cutting-edge solutions for precision engineering, and the Vertical Cylinder Honing Machine is testament to the company's commitment to innovation and excellence. With a team of experienced engineers and technicians, the company has been at the forefront of developing advanced machining solutions that meet the evolving needs of modern manufacturing.The company's dedication to quality and reliability is reflected in every aspect of the Vertical Cylinder Honing Machine. From its robust construction to its precise performance, this machine embodies the values that [Company Name] is known for.With its launch, the Vertical Cylinder Honing Machine has already garnered attention from manufacturers looking to elevate their honing capabilities. The machine's ability to deliver exceptional surface finishes and precise dimensions has made it a game-changer in the industry, setting a new standard for honing machines.As the manufacturing industry continues to evolve, the need for precision and efficiency has never been greater. The Vertical Cylinder Honing Machine from [Company Name] is poised to meet these demands head-on, providing manufacturers with a cutting-edge solution for their honing needs.In conclusion, the Vertical Cylinder Honing Machine represents a new milestone in precision engineering. With its vertical design, advanced technology, and exceptional performance, this machine is set to redefine the standards of precision honing in the industry. Backed by [Company Name]'s reputation for excellence and innovation, the Vertical Cylinder Honing Machine is poised to make a significant impact on the manufacturing landscape, delivering unmatched quality and efficiency to manufacturers around the world.

High-Quality Engine Cylinder Honing Machine for Your Business Needs

The Engine Cylinder Honing Machine, developed by {company name}, is revolutionizing the automotive industry with its cutting-edge technology and precision engineering. This state-of-the-art machine is designed to provide a superior finish to engine cylinders, ensuring optimal performance and efficiency for vehicles.The Engine Cylinder Honing Machine is equipped with advanced honing tools and abrasive stones that are engineered to deliver exceptional results. The machine's high-precision honing process is capable of achieving the exact surface finish required for each individual engine cylinder, ensuring a perfect fit for the piston rings and promoting maximum engine performance.One of the key features of the Engine Cylinder Honing Machine is its ability to automatically adjust the honing pressure and speed, based on the specific requirements of the engine cylinder. This intelligent and adaptive technology ensures that the honing process is always optimized for the best possible results, without the need for manual adjustments.In addition to its advanced honing capabilities, the machine also offers a user-friendly interface that makes it easy for operators to set up and monitor the honing process. This intuitive interface provides real-time feedback on the honing parameters, allowing operators to make quick and precise adjustments as needed.The Engine Cylinder Honing Machine is designed to be versatile and adaptable to a wide range of engine cylinder sizes and configurations. Its innovative design allows for quick and efficient setup, making it suitable for use in both production environments and custom engine building applications.{company name} has a long-standing reputation for excellence in the automotive industry, with a strong commitment to delivering high-quality products and exceptional customer service. The development of the Engine Cylinder Honing Machine is a testament to the company's dedication to innovation and advancement in engine machining technology."We are thrilled to introduce the Engine Cylinder Honing Machine to the market," said {company spokesperson}. "This machine represents a significant advancement in engine cylinder honing technology, and we are confident that it will make a positive impact on the automotive industry. Our team has worked tirelessly to develop a machine that meets the needs of modern engine builders and produces superior results, and we are excited to see the impact it will have on our customers' operations."The Engine Cylinder Honing Machine is set to revolutionize the way engine cylinders are machined, providing a level of precision and performance that is unprecedented in the industry. Its advanced technology and user-friendly interface make it a valuable addition to any automotive production or engine building facility.As the automotive industry continues to evolve, the demand for high-performance engine components will only continue to grow. The Engine Cylinder Honing Machine positions {company name} at the forefront of this industry trend, providing customers with a cutting-edge solution for achieving optimal engine performance and efficiency.In conclusion, the Engine Cylinder Honing Machine from {company name} is a game-changing technology that is set to transform the automotive industry. Its advanced honing capabilities, user-friendly interface, and adaptable design make it a valuable asset for any automotive production or engine building facility. With a strong reputation for excellence and a commitment to innovation, {company name} is poised to make a significant impact with the introduction of this groundbreaking machine.

Find the Best Deals on Deep Hole Drilling Machines

Deep Hole Drilling Machine Price Experiences Significant Growth in the MarketThe deep hole drilling machine price has experienced a significant growth in the market recently, reflecting increasing demand for efficient and precise drilling technology. The global market has witnessed a surge in the demand for deep hole drilling machines across various industrial sectors such as aerospace, automotive, oil and gas, and medical equipment manufacturing.The steady increase in demand for deep hole drilling machines can be attributed to the rise in production activities and the need for high-quality and high-precision drilling operations. Deep hole drilling machines are essential for creating deep, precise, and long holes in various materials, including metals, plastics, and composites. The growing adoption of advanced deep hole drilling technology has propelled manufacturers to invest in innovative and cost-effective drilling solutions.One of the leading players in the deep hole drilling machine market, {}, has been at the forefront of delivering cutting-edge drilling solutions to meet the diverse needs of industrial applications. With a rich history of innovation and expertise in machining technology, {} has established itself as a preferred choice for companies seeking reliable and high-performance drilling equipment.Founded in {}, {} has continually evolved its product line to incorporate the latest advancements in deep hole drilling technology. The company has gained a strong reputation for providing robust, efficient, and precise drilling solutions that offer unmatched performance and reliability. With a focus on delivering tailored solutions to meet specific customer requirements, {} has emerged as a trusted partner for businesses looking to enhance their manufacturing capabilities.{}'s commitment to quality and innovation has set the company apart in the competitive deep hole drilling machine market. By leveraging state-of-the-art manufacturing techniques and advanced engineering expertise, {} has been able to offer a comprehensive range of deep hole drilling machines that cater to a wide spectrum of industrial needs. These machines are designed to deliver exceptional accuracy, speed, and durability, making them ideal for applications that demand high-performance drilling capabilities.Furthermore, {} has also been proactive in addressing the evolving needs of the market by constantly refining its products and services. The company's dedication to research and development has enabled it to introduce new features and functionalities in its deep hole drilling machines, enhancing their overall efficiency and user experience. As a result, {} has been able to stay ahead of the curve and meet the growing demand for advanced drilling solutions in the global market.In response to the rising demand for deep hole drilling machines, {} has strategically priced its products to offer excellent value to customers. The company's competitive pricing strategy has made its drilling machines more accessible to a broader range of businesses, thereby expanding its market presence and customer base. By providing cost-effective solutions without compromising on quality, {} has successfully reinforced its position as a leading provider of deep hole drilling technology.Going forward, the deep hole drilling machine market is expected to witness continued growth as industries seek to enhance their production capabilities with cutting-edge drilling technology. With its unwavering commitment to innovation, quality, and customer satisfaction, {} is well-positioned to capitalize on this trend and further solidify its standing as a premier supplier of deep hole drilling machines.As businesses continue to prioritize efficiency, precision, and reliability in their drilling operations, the demand for advanced deep hole drilling machines is likely to remain robust. Through its relentless pursuit of excellence and customer-oriented approach, {} is set to play a pivotal role in meeting this demand and shaping the future of deep hole drilling technology.

High Quality Vertical Honing Machine for Precision Machining

Vertical Honing Machine Offers High-Level Precision and EfficiencyThe precision manufacturing industry has seen a significant increase in demand for high-quality honing machines. These machines are essential for achieving the precise surface finishes and sizing required for various industrial components, such as cylinders, gears, and hydraulic valves. With the increasing demand for precision engineering, the need for advanced honing solutions has become more prominent.One company that has been at the forefront of providing cutting-edge honing machines is {}. With over 20 years of experience in the manufacturing industry, {} has established itself as a leading provider of honing solutions. The company prides itself on its innovative approach to engineering and continuous commitment to delivering high-performance machines.One of the company's standout products is its Vertical Honing Machine, which has been designed to meet the increasing demands for precision and efficiency in honing operations. The machine offers a unique combination of advanced technology, superior build quality, and high-level precision, making it an ideal choice for a wide range of honing applications.The Vertical Honing Machine features a robust and rigid structure, which ensures stability and accuracy during the honing process. This rigidity is essential for achieving consistent and precise results, especially when honing complex geometries and tight tolerances. The machine's vertical design also allows for easy loading and unloading of workpieces, making it a highly efficient solution for high-volume production.One of the key features of {}'s Vertical Honing Machine is its advanced control system, which enables operators to fine-tune the honing process for optimal results. The machine is equipped with intuitive controls that allow for easy adjustment of honing parameters such as speed, pressure, and feed rate. This level of control is essential for achieving the desired surface finishes and sizing requirements, especially for critical components used in industries such as automotive, aerospace, and hydraulics.In addition to its precision and efficiency, the Vertical Honing Machine also offers versatility, allowing for a wide range of honing operations. Whether it's rough honing, finish honing, or sizing, the machine is capable of handling various honing processes with ease. This versatility makes it a valuable asset for manufacturers looking to streamline their honing operations and enhance overall productivity.Moreover, {} provides comprehensive support and service for its Vertical Honing Machine, ensuring that customers can maximize the machine's performance and longevity. The company's team of experienced engineers and technicians are readily available to provide installation, training, and maintenance services, further cementing {}'s commitment to customer satisfaction and success.With the increasing demands for precision and efficiency in the manufacturing industry, the Vertical Honing Machine from {} is poised to make a significant impact. Its advanced technology, high-level precision, and versatility make it an ideal solution for manufacturers looking to elevate their honing operations to new heights. As the industry continues to evolve, {} remains dedicated to providing cutting-edge honing solutions that empower manufacturers to achieve excellence in their production processes.

Effective Gun Drilling on CNC Mill: The Ultimate Guide

Gun Drilling On CNC Mill: Innovating the Manufacturing ProcessIn today's fast-paced and competitive manufacturing industry, companies are constantly seeking new and innovative ways to improve their production processes. One such innovation is the use of gun drilling on CNC mills, which has the potential to greatly improve the efficiency and accuracy of manufacturing processes.The team at [Company] is at the forefront of this innovation, using their expertise in CNC machining to pioneer the use of gun drilling technology in their production processes. With their commitment to staying ahead of the curve and delivering high-quality products to their customers, [Company] has embraced this new technology as a way to enhance their manufacturing capabilities.Gun drilling is a process that allows for deep, straight holes to be drilled into materials with a high degree of precision. This makes it an ideal solution for industries such as aerospace, automotive, and medical, where the demand for complex and precise components is high. By utilizing gun drilling on their CNC mills, [Company] is able to produce components with extremely tight tolerances and exceptional surface finishes, meeting the exacting standards of their customers.The use of gun drilling on CNC mills has also opened up new possibilities for [Company] in terms of the types of projects they can take on. With the ability to produce deep, straight holes in a wide range of materials, the company is now able to tackle projects that were previously considered too challenging or costly. This has allowed them to expand their capabilities and take on new, high-value projects that were previously beyond their reach.In addition to the technical advantages of gun drilling on CNC mills, [Company] has also seen significant improvements in their overall production efficiency. The use of this technology has allowed them to reduce cycle times and increase throughput, leading to shorter lead times and lower production costs. This has not only benefited the company, but has also resulted in improved delivery times and cost savings for their customers.Furthermore, the implementation of gun drilling on CNC mills has also had a positive impact on the company's environmental footprint. By reducing the amount of material waste and energy consumption, [Company] has been able to minimize their environmental impact and operate in a more sustainable manner. This commitment to sustainability has not gone unnoticed by their customers, many of whom are increasingly seeking out suppliers who prioritize environmental responsibility.As a result of their success with gun drilling on CNC mills, [Company] has established themselves as a leader in the industry, attracting new customers and gaining recognition for their innovative approach to manufacturing. Their investment in this technology has not only allowed them to stay competitive in a rapidly evolving market, but has also positioned them for continued growth and success in the years to come.In conclusion, the use of gun drilling on CNC mills has proven to be a game-changer for [Company], allowing them to produce high-quality components with unmatched precision and efficiency. With their forward-thinking approach and commitment to innovation, [Company] has set themselves apart as a leading supplier in the manufacturing industry, and has positioned themselves for continued success in the future.

Ultimate Guide to Deep Hole Drilling Applications

Deep Hole Drilling ApplicationsDeep hole drilling is a crucial process in a variety of industries, from aerospace and automotive, to medical and oil & gas. It involves drilling holes with a depth-to-diameter ratio of more than 10:1, and requires precision, accuracy, and efficiency. Deep hole drilling is used to produce components such as rifle barrels, oil field drilling equipment, and hydraulic cylinders, among others.A leader in the deep hole drilling industry, {} has been providing innovative solutions for deep hole drilling applications for over 50 years. Using state-of-the-art technology and a commitment to continuous improvement, {} has established itself as a trusted partner for companies in a wide range of industries.One of the key strengths of {} is its ability to tailor its deep hole drilling solutions to meet the specific needs of its customers. Whether it's producing custom tools for unique drilling requirements or developing specialized processes for complex components, {} has the expertise and flexibility to deliver results that exceed expectations.The company’s deep hole drilling applications range from gun drilling, BTA drilling, and ejector drilling, to counterboring, skiving and roller burnishing. These processes are used to create high-quality bores with close tolerances, excellent surface finishes, and the ability to work with a wide range of materials, including metals, plastics, and composites.One of {}'s most noteworthy achievements is its contribution to the aerospace industry. With the increasing demand for lightweight, high-performance aircraft components, there is a growing need for deep hole drilling solutions that can meet the industry's stringent requirements. {} has risen to the challenge by developing advanced drilling processes and tooling that enable the production of complex, high-precision aerospace components with exceptional quality and reliability.In addition to aerospace, {} has also made significant contributions to the automotive industry. With the industry's shift towards electric and hybrid vehicles, there is a need for deep hole drilling solutions that can accommodate the unique requirements of these emerging technologies. {} has been at the forefront of this transition, providing innovative drilling solutions for motor shafts, battery casings, and other critical components that are essential for the next generation of vehicles.Furthermore, in the medical field, {} has played a crucial role in the production of medical implants, surgical instruments, and other precision medical devices. The company's deep hole drilling expertise has enabled it to meet the demanding requirements of the medical industry, including tight tolerances, biocompatibility, and corrosion resistance, while ensuring the highest standards of quality and performance.Another key area of expertise for {} is the oil & gas industry. With its ability to drill deep, precise holes in a variety of materials, {} has provided critical solutions for the production of oil field drilling equipment, downhole tools, and other components that are essential for the exploration and extraction of oil and gas resources.With its extensive experience and expertise in deep hole drilling applications, {} is well positioned to meet the evolving needs of its customers across a wide range of industries. Whether it's developing innovative drilling processes, custom tooling, or specialized solutions for complex components, {} continues to be a trusted partner for companies looking to achieve the highest levels of precision, quality, and efficiency in their deep hole drilling applications.