Highly Efficient Long Hole Drilling Machine Unveiled for Mining Operations

By:Admin

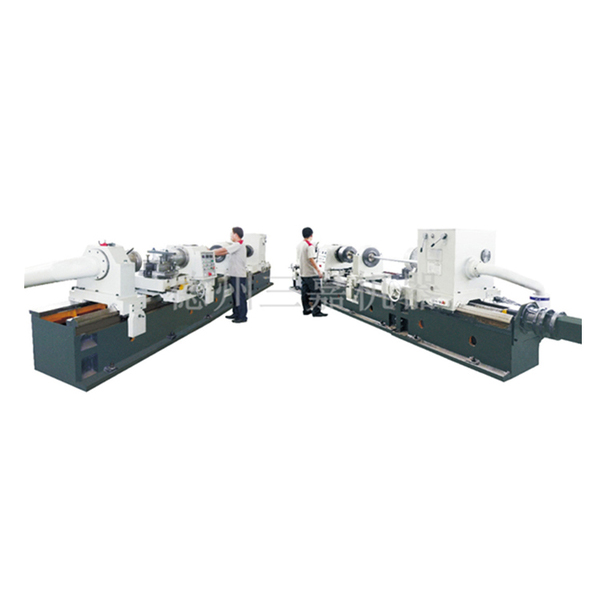

The mining industry has evolved significantly over the years, with technological advancements playing a crucial role in driving efficiency and productivity. One of the latest innovations to make its mark in the industry is the Long Hole Drilling Machine, which has been developed by a leading mining equipment manufacturer.

This state-of-the-art machine has been designed to perform long hole drilling in underground mining operations, offering a more efficient and cost-effective solution compared to traditional drilling methods. Its advanced capabilities have quickly garnered attention from mining companies around the world, paving the way for a new era in underground mining.

The Long Hole Drilling Machine boasts a range of features that set it apart from conventional drilling equipment. Its high-powered hydraulic system allows for faster and more precise drilling, while its automated functions minimize the need for manual intervention, reducing the risk of human error. Additionally, the machine's compact design enables it to navigate through narrow tunnels and reach depths that were previously unattainable with traditional drilling equipment.

In addition to its impressive capabilities, the Long Hole Drilling Machine also prioritizes safety and environmental sustainability. Its integrated safety mechanisms ensure the well-being of operators, while its efficient energy consumption minimizes the machine's impact on the environment. These features have earned the machine accolades from industry experts, further solidifying its reputation as a game-changer in the mining sector.

The company behind the development of the Long Hole Drilling Machine has established itself as a leader in the field of mining equipment manufacturing. With a history of delivering cutting-edge solutions to the industry, the company has gained the trust of mining companies worldwide, earning a reputation for reliability and innovation.

In line with its commitment to excellence, the company has invested heavily in research and development to bring the Long Hole Drilling Machine to fruition. Through collaboration with industry experts and extensive testing in real-world mining scenarios, the company has ensured that the machine meets the highest standards of quality and performance.

Moreover, the company has placed a strong emphasis on customer satisfaction, offering comprehensive technical support and training programs to mining companies that adopt the Long Hole Drilling Machine. By providing ongoing assistance and maintenance services, the company aims to maximize the machine's operational efficiency and longevity, further enhancing its value to its users.

The introduction of the Long Hole Drilling Machine comes at a time when the mining industry is seeking innovative solutions to improve productivity and minimize costs. With its ability to streamline the drilling process and unlock new possibilities in underground mining, the machine is poised to bring about a significant shift in the way mining operations are conducted.

As mining companies continue to embrace the Long Hole Drilling Machine, the industry can expect to witness notable improvements in operational efficiency and safety. The machine's advanced capabilities have the potential to redefine underground mining practices, setting a new standard for productivity and sustainability.

In conclusion, the Long Hole Drilling Machine has emerged as a groundbreaking innovation that has the power to revolutionize the mining industry. With its cutting-edge technology, commitment to safety, and environmental consciousness, the machine is a testament to the potential of technological advancements to drive progress in the field of mining. As the industry continues to evolve, the Long Hole Drilling Machine stands as a beacon of innovation, offering a glimpse into the future of underground mining.

Company News & Blog

High Precision Gun Drilling Machine for Precision Engineering Applications

CNC Gun Drilling Machine Revolutionizing Precision Drilling in Manufacturing IndustryIn today's rapidly advancing and demanding manufacturing industry, precision and efficiency are key factors for success. As a result, companies are constantly seeking innovative solutions to enhance their manufacturing processes and maximize productivity. One such solution that has been gaining traction in the industry is the CNC Gun Drilling Machine.The CNC Gun Drilling Machine, offered by a leading manufacturing technology provider, is a state-of-the-art drilling system that has been revolutionizing the way precision drilling is conducted in the manufacturing industry. This advanced machine is designed to meet the high demands of modern manufacturing processes, offering unparalleled accuracy, speed, and reliability.The CNC Gun Drilling Machine utilizes advanced computer numerical control (CNC) technology to automate the drilling process, ensuring precise and consistent drilling results with minimal human intervention. This not only improves the overall quality of the products being manufactured but also significantly reduces the potential for human error, ultimately leading to higher efficiency and cost savings for companies.With its ability to drill deep, straight, and accurate holes in a wide range of materials, including metal, plastic, and composites, the CNC Gun Drilling Machine has become an indispensable tool for manufacturers across various industries. Whether it's for automotive components, aerospace parts, medical instruments, or mold making, this innovative machine has proven to be a game-changer for companies seeking to push the boundaries of precision engineering.The company behind this revolutionary technology has been at the forefront of developing cutting-edge manufacturing solutions for over two decades. With a strong focus on research and development, the company has consistently pushed the boundaries of innovation to provide its customers with the most advanced and reliable technology available in the market.In addition to the CNC Gun Drilling Machine, the company offers a comprehensive range of manufacturing equipment and solutions, including CNC machining centers, turning machines, milling machines, and more. With a commitment to delivering high-quality products and exceptional customer service, the company has built a solid reputation as a trusted partner for manufacturers seeking to elevate their production capabilities.Moreover, the company's team of highly skilled engineers and technicians are dedicated to providing comprehensive support to their customers, from the initial consultation and installation to ongoing maintenance and technical assistance. This ensures that customers can fully leverage the capabilities of the CNC Gun Drilling Machine and other manufacturing equipment to optimize their production processes and achieve their desired outcomes.With a strong emphasis on continuous improvement and customer satisfaction, the company has established strong partnerships with manufacturers worldwide, serving a diverse range of industries and applications. By understanding the unique needs and challenges of their customers, the company is able to tailor their solutions to address specific requirements, ultimately driving success and growth for their partners.As the manufacturing industry continues to evolve and demand higher levels of precision and efficiency, the CNC Gun Drilling Machine offered by this innovative company is poised to play a pivotal role in shaping the future of manufacturing. Its ability to deliver unmatched drilling precision, speed, and reliability has already garnered widespread attention and adoption across the industry, and it is expected to continue making significant contributions to the advancement of manufacturing technology.In conclusion, the CNC Gun Drilling Machine offered by this industry-leading manufacturing technology provider is a game-changing solution that is redefining the standards of precision drilling in the manufacturing industry. With its advanced capabilities, reliability, and exceptional customer support, the company is poised to lead the way in delivering cutting-edge solutions that empower manufacturers to achieve new levels of productivity and quality in their production processes.

High Precision Gun Barrel Drilling Machine for Manufacturing Purposes

Gun Barrel Drilling Machine Revolutionizes the Firearms Manufacturing IndustryGun Barrel Drilling Machine is a revolutionary piece of equipment that has changed the landscape of the firearms manufacturing industry. This advanced machine has brought about significant improvements in efficiency, precision, and quality, leading to a major overhaul in the way gun barrels are produced.{Company name}, the company behind this groundbreaking technology, has been at the forefront of innovation in the manufacturing sector for several decades. With a strong commitment to research and development, the company has consistently pushed the boundaries of what is possible in the field of industrial machinery. The introduction of the Gun Barrel Drilling Machine is a testament to their dedication to creating cutting-edge solutions that address the evolving needs of the industry.The Gun Barrel Drilling Machine is designed to streamline the production process of gun barrels, which are critical components of firearms. Traditionally, the drilling of gun barrels has been a labor-intensive and time-consuming task that requires a high level of precision and skill. However, this machine has changed the game by automating the drilling process with unparalleled accuracy and speed.One of the key features of the Gun Barrel Drilling Machine is its ability to maintain consistent and precise dimensions throughout the entire drilling process. This is achieved through the use of advanced technology and cutting-edge manufacturing techniques, ensuring that every gun barrel produced is of the highest quality. In addition, the machine is equipped with intelligent software that allows for customization and flexibility, enabling manufacturers to produce a wide variety of gun barrel designs with ease.The introduction of the Gun Barrel Drilling Machine has had a profound impact on the firearms manufacturing industry. With its ability to significantly reduce production time and costs, manufacturers are now able to meet the growing demand for firearms more efficiently. This has not only resulted in increased profitability for companies, but also a more reliable supply of firearms for consumers.Furthermore, the precision and consistency of the gun barrels produced by this machine have led to improvements in firearm performance. By ensuring that each barrel meets exact specifications, the machine has contributed to the overall quality and reliability of firearms on the market. This has not gone unnoticed by consumers, who have become increasingly discerning when it comes to the firearms they purchase.The Gun Barrel Drilling Machine has also had a positive impact on the labor force within the firearms manufacturing industry. By automating the drilling process, the machine has reduced the need for manual labor, freeing up skilled workers to focus on other aspects of production. This has led to a more efficient use of resources and a greater emphasis on the development of specialized skills within the workforce.In addition to its impact on the manufacturing sector, the Gun Barrel Drilling Machine has also contributed to advancements in firearms technology as a whole. Its precision drilling capabilities have opened up new possibilities for the design and engineering of gun barrels, leading to the development of firearms with enhanced performance and functionality.Looking ahead, {Company name} remains committed to further innovation in the firearms manufacturing industry. With the success of the Gun Barrel Drilling Machine, the company is poised to continue pushing the boundaries of what is possible in the field of industrial machinery. By staying at the forefront of technological advancements, {Company name} aims to drive the industry forward and contribute to the ongoing evolution of firearms manufacturing.In conclusion, the introduction of the Gun Barrel Drilling Machine has been a game-changer for the firearms manufacturing industry. Its precision, efficiency, and impact on overall quality have solidified its place as an essential piece of equipment for manufacturers. With the continued dedication of {Company name} to innovation, the future of firearms manufacturing looks brighter than ever.

Efficient Honing Machines for Precision Metal Finishing - A Promising Breakthrough in Manufacturing Technology

Precision Honing Machine Leads the Way in Innovation and QualityPrecision Honing Machine, a leading manufacturer in the field of honing equipment, continues to deliver cutting-edge solutions that redefine the industry standards. With a focus on innovation, quality, and customer satisfaction, Precision Honing Machine has established itself as a trusted name in the global market.Founded in [year], Precision Honing Machine has been dedicated to developing and producing high-precision honing machines that cater to a wide range of industries, including automotive, aerospace, hydraulic cylinders, and defense. The company's commitment to research and development ensures that their machines are at the forefront of technological advancement, enabling customers to boost productivity and improve efficiency in their operations.At the heart of Precision Honing Machine's success is their team of highly skilled engineers and technicians who possess deep expertise in the honing industry. They constantly strive to design and manufacture machines that meet the evolving needs of customers in today's dynamic market. By leveraging the latest technologies and employing rigorous quality control measures, the company ensures that every honing machine that leaves their production line is reliable, durable, and of exceptional performance.One of Precision Honing Machine's flagship products is the [model name], which has garnered widespread acclaim for its superior precision and efficiency. Equipped with state-of-the-art features and functionalities, this machine offers unparalleled control and accuracy, resulting in an impeccable surface finish. The [model name] is designed to meet the diverse needs of various industries and can efficiently hone materials ranging from metals to ceramics.The key differentiating factor that sets Precision Honing Machine apart from its competitors is its unwavering commitment to customer satisfaction. The company takes a customer-centric approach, working closely with clients to understand their specific requirements. By doing so, they are able to tailor their solutions to offer a truly bespoke experience. Additionally, Precision Honing Machine provides comprehensive after-sales support, including installation, training, and maintenance services, ensuring that customers derive maximum value from their investment.In an increasingly competitive market, Precision Honing Machine consistently strives to stay ahead of the curve through continuous innovation. The company invests heavily in research and development, collaborating with renowned industry experts and academic institutions to explore cutting-edge technologies. This commitment has resulted in several groundbreaking advancements, enabling Precision Honing Machine to maintain its position as an industry pioneer.Furthermore, Precision Honing Machine adheres to stringent quality control processes, ensuring that their products pass rigorous tests before they are delivered to customers. By doing so, they maintain exceptional standards, providing customers with reliable machines that outperform their expectations. This commitment to quality has earned Precision Honing Machine numerous certifications and accolades, further solidifying its reputation as a trusted supplier in the honing industry.Looking to the future, Precision Honing Machine aims to continue pushing the boundaries of honing technology, providing even more efficient, precise, and innovative solutions. The company seeks to expand its global presence by forging strategic partnerships and strengthening its distribution network. Moreover, Precision Honing Machine remains committed to sustainability, with a focus on developing eco-friendly machines and implementing green manufacturing practices.In conclusion, Precision Honing Machine has proven itself to be a leading force in the honing industry through its dedication to innovation, quality, and customer satisfaction. With a team of experienced engineers, a range of cutting-edge products, and a customer-centric approach, Precision Honing Machine is well-positioned to shape the future of honing technology.

Honing Tools: A Guide to CNC Machine Honing Techniques

Cnc Honing Tools, a leading manufacturer in the industrial cutting tool industry, has recently announced the release of their latest line of cutting-edge honing tools. With a reputation for producing high-quality, precision-engineered tools, Cnc Honing Tools has become a trusted name among machinists and manufacturers around the world.Founded in [year], Cnc Honing Tools has been dedicated to meeting the needs of their customers by providing innovative solutions for honing and machining applications. With a focus on research and development, the company has continuously worked to improve their product offerings and stay at the forefront of technological advancements in the industry.The new line of honing tools features advanced designs and materials that are engineered to deliver superior performance and durability. Cnc Honing Tools has leveraged their expertise and state-of-the-art manufacturing processes to create tools that are capable of achieving tight tolerances and producing exceptional surface finishes.One of the key features of the new honing tools is their versatility. The tools are designed to be compatible with a wide range of machinery and can be used for honing applications in various industries, including automotive, aerospace, and general engineering. This flexibility makes the tools an ideal choice for manufacturers that need to hone different materials and components.In addition to their versatility, the new honing tools are also designed to be easy to use and maintain. Cnc Honing Tools understands the importance of efficiency and productivity in manufacturing operations, and has ensured that their tools are user-friendly and require minimal upkeep. This allows machinists to focus on their work without being hindered by the tools they use.Furthermore, Cnc Honing Tools has prioritized the durability of their new honing tools. The company knows that reliability is crucial in manufacturing, and has engineered their tools to withstand the demands of heavy-duty usage. With proper care and maintenance, the tools are designed to have a long lifespan, providing consistent performance over time.In a statement, a spokesperson for Cnc Honing Tools expressed excitement about the release of the new honing tools, stating, "We are thrilled to introduce our latest line of honing tools to the market. Our team has put in extensive effort to develop tools that meet the evolving needs of the industry, and we are confident that our customers will find great value in these new offerings."The spokesperson also emphasized the company's commitment to customer satisfaction, saying, "At Cnc Honing Tools, we are dedicated to providing our customers with the best solutions for their honing and machining needs. We believe that our new line of honing tools will further demonstrate our dedication to quality and innovation."As a leading manufacturer in the industrial cutting tool industry, Cnc Honing Tools has a global presence, with a network of distributors and partners that serve customers in various regions. The company's reputation for excellence and reliability has solidified its position as a preferred supplier for many businesses.In conclusion, the release of Cnc Honing Tools' new line of honing tools represents a significant advancement in the industry. With their history of innovation and commitment to quality, the company has demonstrated its ability to deliver tools that meet the rigorous demands of modern manufacturing. As Cnc Honing Tools continues to push the boundaries of what is possible in honing and machining, they are poised to maintain their status as a standout leader in the industry.

The Ultimate Guide to Single Cylinder Honing Machines: Everything You Need to Know

Single Cylinder Honing Machine: The Latest Addition to the Product Line of a Leading Manufacturing Company{Company Name}, a renowned manufacturer of precision tools and equipment, has recently announced the launch of their latest product, the Single Cylinder Honing Machine. This cutting-edge machine is designed to provide superior honing and surface finishing capabilities for a wide range of industrial applications. With over {number} years of experience in the manufacturing industry, {Company Name} has earned a reputation for delivering high-quality products that meet the diverse needs of their customers.The Single Cylinder Honing Machine is the result of extensive research and development efforts by {Company Name}'s team of skilled engineers and technicians. It is specifically engineered to offer precision honing for single cylinder engine blocks, ensuring optimal surface quality and dimensional accuracy. The machine boasts advanced features such as high-precision honing tools, a robust honing spindle, and a user-friendly control interface, making it an ideal choice for manufacturers seeking to enhance the performance and durability of their engine components.One of the key highlights of the Single Cylinder Honing Machine is its versatility, as it can accommodate a wide range of bore sizes and materials, including cast iron, steel, aluminum, and other alloys. This flexibility allows manufacturers to hone different types of engine blocks and cylinders with ease, thereby streamlining their production processes and improving overall efficiency. Additionally, the machine's automated honing cycle and integrated coolant system ensure consistent performance and prolonged tool life, contributing to cost savings and higher productivity.In line with {Company Name}'s commitment to customer satisfaction, the Single Cylinder Honing Machine is backed by comprehensive technical support and after-sales service. The company's team of experts is readily available to provide assistance with installation, training, and troubleshooting, ensuring that customers can maximize the potential of the machine and achieve optimal results in their operations. Furthermore, {Company Name} offers customizable tooling solutions and honing parameters to suit specific manufacturing requirements, further enhancing the value proposition of the Single Cylinder Honing Machine."We are thrilled to introduce the Single Cylinder Honing Machine to the market, as it represents a significant advancement in our product portfolio," said {Spokesperson Name}, the CEO of {Company Name}. "This machine exemplifies our dedication to innovation and excellence, and we are confident that it will empower our customers to elevate their honing processes and achieve superior surface finishes for their engine components."The launch of the Single Cylinder Honing Machine underscores {Company Name}'s ongoing commitment to meeting the evolving needs of the manufacturing industry and delivering cutting-edge solutions that drive operational efficiency and quality performance. With its proven track record of providing reliable and technologically advanced equipment, {Company Name} continues to be a trusted partner for businesses seeking to elevate their manufacturing capabilities and stay ahead in a competitive market landscape.To learn more about the Single Cylinder Honing Machine and other products offered by {Company Name}, interested parties can visit the company's website or contact their sales representatives for personalized consultations and demonstration sessions. As the manufacturing industry continues to evolve, {Company Name} remains at the forefront, providing innovative solutions that empower businesses to thrive and succeed in a dynamic market environment.

Revolutionary Automatic Honing Machine Redefines Precision Engineering

[Title]Innovative Automatic Honing Machine Revolutionizes Precision Manufacturing Processes[Subtitle]Cutting-edge technology brings efficiency, accuracy, and high-quality results to the manufacturing industry[Company Introduction]Established over 25 years ago, our company has been at the forefront of developing cutting-edge solutions for precision manufacturing processes. With a strong focus on innovation and customer satisfaction, we have continuously strived to revolutionize the industry by introducing advanced machinery and equipment. Our commitment to providing the highest quality products has led us to develop the groundbreaking Automatic Honing Machine, which promises to transform the way honing is conducted.[Paragraph 1]Precision and efficiency have always been crucial aspects in the manufacturing industry. The introduction of our Automatic Honing Machine has revolutionized the honing process, enabling a level of accuracy and speed that was once unimaginable. This state-of-the-art technology has eliminated the need for manual honing, reducing human error and ensuring consistent and impeccable results every time.[Paragraph 2]Gone are the days of relying on skilled technicians to manually hone every part. With our Automatic Honing Machine, manufacturers can now experience a level of efficiency that significantly improves productivity. By automating the honing process, companies can save valuable time and resources, allowing for higher output and increased profitability.[Paragraph 3]The Automatic Honing Machine utilizes advanced software and cutting-edge robotics to precisely hone components with unprecedented accuracy. The machine's intuitive interface allows operators to easily program specific honing parameters, ensuring that each component meets the exacting standards set by manufacturers. This level of precision guarantees that every honed part is consistent in quality, contributing to the overall improvement of the manufacturing process.[Paragraph 4]Beyond its exceptional accuracy and efficiency, the Automatic Honing Machine also boasts remarkable versatility. With its adaptable design, the machine can handle a wide range of components, making it suitable for various industries. From automotive parts to aerospace components, this innovative technology offers manufacturers an all-in-one solution for their honing needs.[Paragraph 5]Our commitment to sustainability is reflected in the design of the Automatic Honing Machine. By optimizing the honing process and reducing waste, this technology helps minimize environmental impact. The machine's energy-efficient operation contributes to a greener and more sustainable manufacturing industry.[Paragraph 6]In addition to its impressive technical features, our company stands out for its exceptional customer service. With a team of highly skilled professionals, we provide comprehensive training and support to ensure that manufacturers can fully utilize the capabilities of the Automatic Honing Machine. Our dedication to customer satisfaction is unmatched in the industry, and we strive to establish long-lasting partnerships with our clients.[Paragraph 7]As the manufacturing industry continues to evolve, our company remains committed to pushing boundaries and introducing innovative solutions. The Automatic Honing Machine is just one example of our relentless pursuit of excellence. With its advanced technology and exceptional performance, this revolutionary machine will undoubtedly shape the future of precision manufacturing processes.[Conclusion]With the introduction of the Automatic Honing Machine, our company has once again proven its dedication to revolutionizing the manufacturing industry. Through its exceptional accuracy, efficiency, and versatility, this cutting-edge technology promises to deliver unparalleled results for manufacturers across various sectors. As we strive to provide innovative solutions, our commitment to customer satisfaction remains at the core of everything we do. Together with our Automatic Honing Machine, we aim to continue pushing the boundaries of what is possible in precision manufacturing.

Advanced Deep Hole Boring and Scraping Machine for Precision Machining

CNC Deep Hole Boring And Scraping Machine Revolutionizes ManufacturingIn a groundbreaking development for the manufacturing industry, a leading company has introduced a state-of-the-art CNC Deep Hole Boring And Scraping Machine. This cutting-edge technology is set to revolutionize the way deep hole boring and scraping operations are carried out, offering unprecedented precision and efficiency.{Company Name}, a renowned name in the field of industrial machinery, has long been at the forefront of innovation in manufacturing technology. With a history of delivering high-quality and advanced solutions to the industry, the company has once again raised the bar with the introduction of their CNC Deep Hole Boring And Scraping Machine.The CNC Deep Hole Boring And Scraping Machine is designed to tackle the most challenging tasks with ease and precision. Its advanced CNC capabilities allow for complex machining operations to be performed with unmatched accuracy, ensuring that the end product meets the most stringent quality standards. This level of precision is particularly crucial in industries such as aerospace, automotive, and oil and gas, where the demand for flawless components is non-negotiable.One of the key features of the CNC Deep Hole Boring And Scraping Machine is its ability to efficiently remove material from the workpiece while maintaining tight tolerances. This is made possible by the machine's advanced scraping technology, which ensures smooth and uniform material removal without compromising the integrity of the component. As a result, manufacturers can achieve the desired surface finish and dimensional accuracy with minimum effort and maximum repeatability.Moreover, the CNC Deep Hole Boring And Scraping Machine is equipped with smart automation features that streamline the manufacturing process and minimize human intervention. This not only improves productivity but also reduces the likelihood of errors, ultimately leading to cost savings and enhanced overall efficiency in the production line.In addition to its cutting-edge technological capabilities, the CNC Deep Hole Boring And Scraping Machine is also designed with user-friendliness in mind. The intuitive interface and ergonomic design make it easy for operators to set up and oversee the machining process, reducing the learning curve and enabling swift adoption of the technology.{Company Name} takes pride in the robust support and service network it offers to its customers. With the introduction of the CNC Deep Hole Boring And Scraping Machine, the company is committed to providing comprehensive training and after-sales support to ensure that users can harness the full potential of this advanced technology.The unveiling of the CNC Deep Hole Boring And Scraping Machine marks a significant milestone for {Company Name} and underlines its dedication to pushing the boundaries of manufacturing technology. By combining cutting-edge innovation with practicality and reliability, the company continues to set new standards in the industry, empowering manufacturers to achieve new levels of precision and productivity.In conclusion, the introduction of the CNC Deep Hole Boring And Scraping Machine by {Company Name} is poised to make a lasting impact on the manufacturing landscape. With its unparalleled precision, efficiency, and user-friendly design, this advanced technology is set to redefine the way deep hole boring and scraping operations are carried out, offering manufacturers a competitive edge in today's demanding market.

High-precision Cylinder Honing Machine for CNC Applications

CNC Cylinder Honing Machine: A Game Changer in the Manufacturing IndustryIn the world of manufacturing, precision and efficiency are crucial. The demand for high-quality products and the need to streamline production processes has driven manufacturers to seek advanced technologies and equipment. One such technological advancement that is making waves in the manufacturing industry is the CNC Cylinder Honing Machine.The CNC Cylinder Honing Machine is a state-of-the-art equipment that has revolutionized the honing process for cylinder bores. This machine is designed to provide highly accurate and consistent honing results, making it an indispensable tool for manufacturers in various industries.As the name suggests, the CNC Cylinder Honing Machine is a computer numerical control (CNC) operated machine, which means that it is fully automated and can be programmed to perform precise honing operations. This level of automation not only ensures a high degree of accuracy but also significantly reduces the need for manual intervention, thus improving overall productivity.One of the key players in the manufacturing industry that has been at the forefront of developing and supplying CNC Cylinder Honing Machines is {company name}. Established over {number} years ago, {company name} has been a pioneer in the field of precision engineering and manufacturing equipment. The company has earned a stellar reputation for its commitment to delivering cutting-edge solutions that meet the ever-evolving needs of the industry.{company name}’s CNC Cylinder Honing Machine is a testament to the company's dedication to innovation and excellence. Equipped with advanced technology and engineering, this machine offers a range of features that set it apart from traditional honing machines. Its precision honing capability, coupled with its automated operation, allows for a level of accuracy and consistency that was previously unattainable. This has not only helped manufacturers improve the quality of their products but has also resulted in significant cost savings.The versatility of {company name}’s CNC Cylinder Honing Machine is another standout feature. It can accommodate a wide range of cylinder bore sizes and materials, making it suitable for use in various industries, including automotive, aerospace, marine, and hydraulic equipment manufacturing. This flexibility has made it an indispensable tool for manufacturers who need to hone different types of cylinder bores with varying specifications.Furthermore, {company name} has placed a strong emphasis on the user-friendliness of its CNC Cylinder Honing Machine. The machine's intuitive interface and easy-to-use controls make it accessible to operators of varying skill levels. This means that manufacturers can integrate this advanced technology into their production processes without the need for extensive retraining or hiring specialized technicians.In addition to its cutting-edge technology, {company name} is also committed to providing exceptional customer support and service. The company's team of experts is readily available to assist clients with installation, training, and ongoing maintenance of the CNC Cylinder Honing Machine. This dedication to customer satisfaction has earned {company name} a loyal and satisfied customer base, solidifying its position as a trusted partner in the manufacturing industry.The impact of {company name}'s CNC Cylinder Honing Machine on the manufacturing industry has been nothing short of game-changing. Its ability to deliver precision, efficiency, and versatility has enabled manufacturers to elevate their production processes to new heights. As the demand for high-quality products continues to grow, the need for advanced technologies like the CNC Cylinder Honing Machine will only become more pronounced, propelling {company name} to the forefront of innovation and excellence.

Revolutionizing Cylinder Honing Machines: Unveiling the Latest CNC Innovation

Title: Cutting-Edge CNC Cylinder Honing Machine Revolutionizes Precision Machining IndustryIntroduction:In a breakthrough move, a leading engineering firm has unveiled its latest innovation in the field of precision machining: the state-of-the-art CNC Cylinder Honing Machine. This cutting-edge technology promises to revolutionize the industry by delivering unparalleled precision, enhanced productivity, and improved efficiency in cylinder honing processes.Company Background:With a rich legacy spanning several decades, the company has emerged as a global leader in producing advanced machinery for the manufacturing and engineering industry. Committed to pushing the boundaries of innovation, the company has consistently developed groundbreaking solutions to meet ever-evolving industry demands. Boasting a highly skilled team of engineers and technicians, the firm has become synonymous with excellence and reliability.The CNC Cylinder Honing Machine:The unveiling of the CNC Cylinder Honing Machine signifies a significant milestone for the company and the precision machining industry at large. Built upon cutting-edge technology and years of expertise, this advanced equipment is set to change the game for manufacturers and engineers alike.1. Uncompromised Precision:The CNC Cylinder Honing Machine is designed to deliver exceptional precision in honing cylinders of varying sizes and materials. Utilizing advanced CNC controls, the machine ensures accurate and consistent results, eliminating errors commonly associated with traditional honing methods. Equipped with high-resolution sensors and monitoring systems, this sophisticated machine guarantees precision at every step of the process, resulting in superior surface finishes and optimal cylinder geometry.2. Enhanced Productivity:With rapid advancements in automation, the CNC Cylinder Honing Machine significantly improves productivity, thereby reducing downtime and maximizing operational efficiency. The automated process eliminates the need for manual intervention, ensuring uninterrupted operations and increased output. Moreover, the machine's ability to simultaneously handle multiple cylinders minimizes production timelines and increases overall efficiency, enabling manufacturers to meet tight deadlines without compromising quality.3. Improved Flexibility:Recognizing the diverse requirements of the modern manufacturing industry, the CNC Cylinder Honing Machine offers unmatched versatility. With its user-friendly interface and intuitive controls, operators can effortlessly adjust and customize parameters to accommodate a wide range of cylinder sizes, materials, and honing specifications. This adaptability saves both time and resources by eliminating the need for additional machinery or reconfigurations, resulting in a streamlined and cost-effective honing process.4. Cutting-Edge Features:The CNC Cylinder Honing Machine is integrated with several advanced features that further enhance its performance and functionality. Its intelligent lubrication system ensures optimal lubrication in real-time, contributing to component longevity. Additionally, the machine's self-diagnostic capabilities enable preemptive identification of potential issues, reducing maintenance costs and eliminating unexpected breakdowns. Furthermore, the machine's eco-friendly design incorporates energy-saving features, demonstrating the company's commitment to sustainable manufacturing practices.Conclusion:The introduction of the CNC Cylinder Honing Machine signifies a remarkable milestone in the precision machining industry. Manufacturers and engineers can now look forward to uncompromised precision, enhanced productivity, and improved efficiency, thanks to this cutting-edge technology. With its ability to deliver superior results consistently, this advanced machine ensures the highest standards of quality, reliability, and cost-effectiveness. As the industry embraces the CNC Cylinder Honing Machine, it undoubtedly sets the stage for a new era in precision machining.

Top Gun Drilling Tools for Precision Machining: A Complete Guide

Gun Drilling Tools, a leading manufacturer of high-quality drilling tools, has announced the release of their latest line of innovative drilling solutions. With a strong focus on quality, reliability, and customer satisfaction, the company has established itself as a trusted partner for businesses in the oil and gas, aerospace, automotive, and medical industries.Founded in 1995, Gun Drilling Tools has continuously invested in research and development to create cutting-edge drilling technologies. The company's state-of-the-art manufacturing facilities and team of experienced engineers enable them to design and produce a wide range of drilling tools, including deep hole drills, gun drills, and BTA drills. Their commitment to excellence has earned them a reputation for delivering high-performance products that meet the demanding requirements of their customers.One of the key highlights of Gun Drilling Tools' latest product line is the introduction of their advanced coating technology. This innovative surface treatment not only enhances the durability and longevity of the drilling tools but also improves their overall performance. The proprietary coating is designed to reduce friction, dissipate heat, and prevent chip buildup, resulting in smoother and more efficient drilling operations.In addition to their cutting-edge technology, Gun Drilling Tools takes pride in their dedication to customer service. The company works closely with their clients to understand their specific drilling needs and challenges, offering customized solutions to meet their requirements. Whether it's developing a new tool design or providing technical support, Gun Drilling Tools is committed to delivering excellent service at every step of the process."We are thrilled to introduce our latest line of drilling tools, which represents our ongoing commitment to innovation and excellence," said the spokesperson for Gun Drilling Tools. "We understand the critical role that drilling plays in our customers' operations, and we are dedicated to providing them with the best tools to achieve their objectives. With our advanced coating technology and focus on customer satisfaction, we are confident that our new products will deliver outstanding results."The new line of drilling tools from Gun Drilling Tools is now available for purchase, and the company is already receiving positive feedback from early adopters. Customers have praised the performance and durability of the tools, highlighting their ability to withstand the rigors of demanding drilling applications. With a strong track record of success and a commitment to continuous improvement, Gun Drilling Tools is well-positioned to remain a leader in the industry.In conclusion, Gun Drilling Tools' latest product line exemplifies the company's dedication to innovation, quality, and customer satisfaction. With their advanced coating technology and customized solutions, they continue to provide businesses in various industries with the tools they need to succeed in their drilling operations. As the industry evolves, Gun Drilling Tools remains at the forefront, delivering cutting-edge solutions that empower their customers to achieve their goals.