Unveiling the Advantages of Precision Gun Drilling in Manufacturing Processes

By:Admin

In today's fast-paced world, precision and efficiency are key factors in the success of any manufacturing process. As technology continues to evolve, industries strive to find innovative solutions to meet the increasing demands of their customers. One company that has consistently demonstrated its commitment to excellence in manufacturing is an industry leader in precision gun drilling.

With over three decades of experience, this esteemed company has not only mastered the art of gun drilling but also revolutionized the industry with cutting-edge techniques and state-of-the-art machinery. By incorporating advanced technology into their processes, they have successfully delivered exceptional results to industries ranging from aerospace to medical and everything in between.

Precision gun drilling is a complex process that involves creating deep, straight holes with a high level of accuracy in precision-engineered components. While the conventional drilling process is suitable for most applications, it falls short when it comes to deep holes or those with tight tolerances. This is where precision gun drilling shines, as it provides a reliable and efficient solution for industries that demand immaculate precision and exceptionally high-quality products.

One of the key advantages of precision gun drilling is its exceptional accuracy. By utilizing specialized machinery and cutting tools, this method ensures that holes are drilled with utmost precision, meeting even the most stringent tolerance requirements. This level of accuracy is vital for industries such as aerospace and defense, where even the smallest deviation can have catastrophic consequences. Furthermore, precision gun drilling eliminates the need for secondary operations, reducing production time and cost while increasing overall productivity.

A hallmark of the company's success lies in its dedication to utilizing the latest technology and continuously improving its processes. They have invested significantly in research and development to introduce groundbreaking innovations, enabling them to stay ahead of competition and deliver unparalleled results. Their state-of-the-art machinery and equipment are meticulously designed, engineered, and calibrated to guarantee optimum performance and accuracy.

The company's commitment to quality is also reflected in its rigorous quality control processes. They adhere to stringent international standards, ensuring that every component produced meets the highest level of precision and durability. By implementing comprehensive quality management systems, the company consistently delivers products that exceed customer expectations and industry standards.

Building strong relationships with their customers has been another driving force behind the company's success. They work closely with their clients, understanding their unique requirements, and providing tailored solutions that perfectly align with their needs. This customer-centric approach enables them to forge long-term partnerships and become the go-to provider for precision gun drilling services.

In addition to their exceptional core competencies, the company also places great importance on environmental sustainability. They actively seek environmentally friendly solutions, reducing their carbon footprint, and minimizing waste generation. By investing in energy-efficient machinery and utilizing eco-friendly coolant systems, they demonstrate their commitment to preserving the environment for future generations.

Looking ahead, this industry leader shows no signs of slowing down. With their unwavering focus on innovation, dedication to precision, and customer-centric approach, they are well-positioned to continue paving the way for excellence in manufacturing. As demand for precision engineering grows, this company remains at the forefront of technology and is poised to meet the evolving needs of the industries they serve.

In conclusion, precision gun drilling has emerged as a game-changer in the manufacturing industry, and this company has set the standard for excellence in this field. With their advanced technology, commitment to quality, and customer-centric approach, they have established themselves as an industry leader, consistently delivering superior results. As they continue to push the boundaries of precision engineering, their impact on the manufacturing landscape cannot be overlooked.

Company News & Blog

Boost Engine Performance with High-Quality Cylinder Honing Machines

[Heading] Engine Cylinder Honing Machine: Revolutionizing Precision in Automobile Manufacturing[Subheading] Introducing the Next Generation Engine Cylinder Honing Machine from Innovatix Corp[Date][City, State] - Innovatix Corp, a renowned leader in industrial manufacturing technologies, is all set to revolutionize the automobile manufacturing industry with its latest innovation - the Engine Cylinder Honing Machine. This cutting-edge technology promises to enhance precision and efficiency, taking automobiles to new heights of performance.[Company Background] Innovatix Corp has been at the forefront of revolutionizing various industrial sectors with its groundbreaking technologies. Established in [year], the company has consistently delivered innovative solutions to address the evolving needs of the manufacturing industry. With a dedicated team of engineers and industry experts, Innovatix Corp has become an industry leader, renowned for its commitment to excellence and pushing the boundaries of technological advancement.[Overview] The new Engine Cylinder Honing Machine developed by Innovatix Corp is set to redefine precision and efficiency in engine manufacturing. With its cutting-edge features, this machine ensures that engine cylinders are honed to perfection, resulting in superior performance and reduced emissions.[Precision Redefined]The Engine Cylinder Honing Machine boasts advanced technology that sets it apart from its competitors. It combines state-of-the-art robotics, artificial intelligence, and advanced laser measurements to provide unparalleled precision in honing engine cylinders. This precision ensures that every cylinder is perfectly finished, resulting in optimal engine performance.[Efficiency Enhancements]In addition to its precision, the Engine Cylinder Honing Machine also offers significant efficiency improvements. By automating the honing process, the machine reduces human errors and streamlines production. This translates into faster turnaround times, increased productivity, and cost savings for automobile manufacturers.[Features]1. Robotics: The Engine Cylinder Honing Machine utilizes advanced robotics to handle and position engine cylinders with utmost precision. This eliminates human error and ensures uniform honing throughout the production process.2. Artificial Intelligence: Built-in artificial intelligence algorithms continuously monitor and optimize the honing parameters, adapting to variations in engine cylinder specifications. This intelligent system guarantees consistent quality and reduces wastage.3. Laser Measurements: The machine employs cutting-edge laser measurement technology to achieve micron-level accuracy in cylinder honing. This ensures that each cylinder meets precise specifications, resulting in improved engine performance and durability.4. Customized Honing Programs: The Engine Cylinder Honing Machine allows for the creation of customized honing programs tailored to specific engine designs. This flexibility ensures that the machine can accommodate a wide range of engines and manufacturing requirements.[Benefits]1. Enhanced Engine Performance: The precise honing achieved by the Engine Cylinder Honing Machine maximizes engine performance, delivering increased power, fuel efficiency, and reduced emissions. This results in improved driving experiences for consumers and compliance with environmental regulations.2. Reduced Manufacturing Costs: By minimizing human errors and wastage, the honing machine significantly reduces manufacturing costs for automobile companies. The automated processes also lead to faster production cycles and improved overall productivity.3. Competitive Edge: Automobile manufacturers incorporating the Engine Cylinder Honing Machine will gain a competitive edge in the market. The superior performance and efficiency of their engines will attract customers looking for high-quality and environmentally friendly vehicles.[Conclusion]Innovatix Corp's Engine Cylinder Honing Machine marks a revolutionary leap in precision and efficiency in engine manufacturing. With its advanced features and cutting-edge technology, this machine is set to redefine the automobile industry. Manufacturers utilizing this technology can expect superior engine performance, reduced manufacturing costs, and an unparalleled competitive edge. Innovatix Corp remains committed to pushing the boundaries of innovation, propelling the manufacturing industry into new heights of success and sustainability.

Efficient and Precise Vertical Honing Machines: A Game-Changer in Precision Machining

Vertical Honing Machine Revolutionizes Precision Machining Industry[City], [Date] - Precision machining processes are crucial for achieving the highest levels of accuracy, efficiency, and quality in the manufacturing sector. Recognizing the growing demand for innovation in the field, [Company Name], a leading machine tool manufacturer, has unveiled its latest breakthrough - the Vertical Honing Machine.Designed to revolutionize precision honing processes, the Vertical Honing Machine is poised to transform the manufacturing industry by offering unparalleled precision, efficiency, and versatility. With over [number of] years of experience in developing cutting-edge machinery, [Company Name] has once again delivered an industry-leading solution that caters to the evolving needs of precision manufacturing.The Vertical Honing Machine has been meticulously engineered to address the challenges faced by conventional honing machines. By incorporating state-of-the-art technology and innovative design features, [Company Name] has created a machine that surpasses its competitors in terms of quality, performance, and flexibility.One of the key distinguishing features of the Vertical Honing Machine is its ability to precisely bore and finish cylinders, hydraulic components, and other cylindrical workpieces with utmost accuracy. Equipped with advanced honing tools and a sophisticated control system, this cutting-edge machine ensures optimal surface finishes and dimensional accuracy, meeting the stringent requirements of diverse industries such as automotive, aerospace, hydraulics, and more.The revolutionary design of the Vertical Honing Machine enables it to deliver exceptional stability and rigidity during operation. Its robust structure, combined with advanced motion control mechanisms, guarantees minimized vibration and superior tool positioning. This allows for precise control over parameters such as feed rates, tool pressure, and stroke speed, ensuring consistent and flawlessly finished parts every time.[Company Name] understands that efficiency and productivity are critical components of modern manufacturing. To address this, the Vertical Honing Machine boasts an intuitive user interface that simplifies machine operation and facilitates quick setup changes. With improved ergonomics and user-friendly controls, operators can swiftly adapt to new projects and reduce downtime, translating into higher productivity and profitability for manufacturers.Additionally, the Vertical Honing Machine is equipped with cutting-edge automation features. By integrating robotic loading and unloading systems, [Company Name] has introduced seamless integration between machining operations and material handling. This streamlines the workflow and eliminates the need for manual intervention, further enhancing productivity and reducing operator fatigue.Furthermore, the Vertical Honing Machine offers unparalleled flexibility. With customizable honing parameters and the ability to accommodate a wide range of workpiece sizes and materials, this machine caters to various industry requirements. Its versatility extends to the honing of specialized shapes, interrupted or blind bores, and intricate internal profiles, making it an invaluable asset for manufacturers operating in diverse sectors.[Company Name] is committed to providing outstanding customer support and continuous improvement in their products. In addition to delivering a cutting-edge Vertical Honing Machine, the company offers comprehensive technical assistance, training programs, and aftermarket services. With a global network of service centers and a team of highly skilled professionals, [Company Name] ensures that their customers maximize the potential of the Vertical Honing Machine and achieve the highest levels of productivity and quality.As the manufacturing industry embraces automation, robotics, and digital technologies, precision machining processes are evolving to meet the demands of speed, accuracy, and efficiency. The Vertical Honing Machine from [Company Name] represents a significant leap forward in the field of honing and machining. By leveraging its technological expertise, [Company Name] continues to play a pivotal role in driving innovation and enabling manufacturers to achieve new heights of excellence in precision machining.

Cylinder Liner Honing Tool: Enhancing Engine Performance and Longevity

Cylinder Liner Honing Tool Revolutionizes Engine PerformanceInnovative Technology Maximizes Efficiency and Durability{Company Name} Introduces Industry-Leading Cylinder Liner Honing Tool{City, State} - {Date} - {Company Name}, a pioneering force in the automotive industry, is proud to announce the launch of their groundbreaking Cylinder Liner Honing Tool. This cutting-edge technology promises to revolutionize engine performance, boosting efficiency and durability to unprecedented levels.The cylinder liner is a crucial component of any combustion engine. Its main function is to act as a sleeve, separating the piston from the rest of the engine block. Over time, due to wear and tear, the liner's surface can become rough and uneven, leading to decreased engine performance and increased fuel consumption. Traditionally, the honing of cylinder liners has been a labor-intensive and time-consuming process, often requiring specialized skills and expensive equipment.Enter {Company Name}'s new Cylinder Liner Honing Tool, a game-changer in the industry. Combining cutting-edge technology with extensive research and development, this revolutionary tool offers a quick, efficient, and cost-effective solution to the age-old problem of cylinder liner degradation.With its state-of-the-art design, the Cylinder Liner Honing Tool delivers a perfectly honed surface on the cylinder liner, ensuring optimal engine performance. The tool utilizes diamond-coated honing stones that accurately remove imperfections, creating a smooth surface that reduces friction and boosts fuel efficiency.One of the key advantages of {Company Name}'s Cylinder Liner Honing Tool is its versatility. The tool is compatible with various engine types and sizes, making it a valuable asset not only to automakers but also to engine servicing facilities. Whether it's a small passenger car engine or a heavy-duty commercial vehicle engine, this honing tool can optimize its performance and extend its lifespan.Furthermore, {Company Name}'s Cylinder Liner Honing Tool is designed for ease of use. Its ergonomic handle and intuitive system allow technicians from all skill levels to efficiently hone cylinder liners without the need for extensive training. This streamlined process not only saves time but also minimizes the risk of error, ensuring consistent quality every time.In addition to enhancing engine efficiency, the Cylinder Liner Honing Tool also contributes to reducing emissions. By improving the overall combustion process, the tool helps minimize the release of harmful pollutants into the environment, making it an essential tool for any organization focused on sustainability."We are extremely excited to introduce our Cylinder Liner Honing Tool to the market," says {Company Name}'s CEO. "Our commitment to innovation and customer satisfaction has driven us to develop a tool that will significantly impact engine performance in a positive way. We believe this technology will revolutionize the industry and set new standards for efficiency and durability."{Company Name} has a long-standing reputation for delivering cutting-edge solutions that meet and exceed industry expectations. With the introduction of this Cylinder Liner Honing Tool, the company continues to push boundaries, setting new benchmarks for engine performance in the automotive sector.As the demand for more fuel-efficient and eco-friendly vehicles continues to rise, {Company Name}'s Cylinder Liner Honing Tool arrives at a critical moment in the industry. By optimizing engine performance and reducing emissions, this innovative tool stands as a testament to the company's commitment to shaping a sustainable future.For more information about {Company Name}'s Cylinder Liner Honing Tool and how it can transform engine performance, please visit their official website {Website URL}.About {Company Name}{Company Name} is a leading automotive technology company specializing in cutting-edge solutions for engine efficiency and performance. With a strong focus on innovation and customer satisfaction, the company has established itself as a trusted name in the industry. Headquartered in {City, State}, {Company Name} is committed to shaping a sustainable future through its groundbreaking technologies.

Revolutionizing Cylinder Honing Machines: Unveiling the Latest CNC Innovation

Title: Cutting-Edge CNC Cylinder Honing Machine Revolutionizes Precision Machining IndustryIntroduction:In a breakthrough move, a leading engineering firm has unveiled its latest innovation in the field of precision machining: the state-of-the-art CNC Cylinder Honing Machine. This cutting-edge technology promises to revolutionize the industry by delivering unparalleled precision, enhanced productivity, and improved efficiency in cylinder honing processes.Company Background:With a rich legacy spanning several decades, the company has emerged as a global leader in producing advanced machinery for the manufacturing and engineering industry. Committed to pushing the boundaries of innovation, the company has consistently developed groundbreaking solutions to meet ever-evolving industry demands. Boasting a highly skilled team of engineers and technicians, the firm has become synonymous with excellence and reliability.The CNC Cylinder Honing Machine:The unveiling of the CNC Cylinder Honing Machine signifies a significant milestone for the company and the precision machining industry at large. Built upon cutting-edge technology and years of expertise, this advanced equipment is set to change the game for manufacturers and engineers alike.1. Uncompromised Precision:The CNC Cylinder Honing Machine is designed to deliver exceptional precision in honing cylinders of varying sizes and materials. Utilizing advanced CNC controls, the machine ensures accurate and consistent results, eliminating errors commonly associated with traditional honing methods. Equipped with high-resolution sensors and monitoring systems, this sophisticated machine guarantees precision at every step of the process, resulting in superior surface finishes and optimal cylinder geometry.2. Enhanced Productivity:With rapid advancements in automation, the CNC Cylinder Honing Machine significantly improves productivity, thereby reducing downtime and maximizing operational efficiency. The automated process eliminates the need for manual intervention, ensuring uninterrupted operations and increased output. Moreover, the machine's ability to simultaneously handle multiple cylinders minimizes production timelines and increases overall efficiency, enabling manufacturers to meet tight deadlines without compromising quality.3. Improved Flexibility:Recognizing the diverse requirements of the modern manufacturing industry, the CNC Cylinder Honing Machine offers unmatched versatility. With its user-friendly interface and intuitive controls, operators can effortlessly adjust and customize parameters to accommodate a wide range of cylinder sizes, materials, and honing specifications. This adaptability saves both time and resources by eliminating the need for additional machinery or reconfigurations, resulting in a streamlined and cost-effective honing process.4. Cutting-Edge Features:The CNC Cylinder Honing Machine is integrated with several advanced features that further enhance its performance and functionality. Its intelligent lubrication system ensures optimal lubrication in real-time, contributing to component longevity. Additionally, the machine's self-diagnostic capabilities enable preemptive identification of potential issues, reducing maintenance costs and eliminating unexpected breakdowns. Furthermore, the machine's eco-friendly design incorporates energy-saving features, demonstrating the company's commitment to sustainable manufacturing practices.Conclusion:The introduction of the CNC Cylinder Honing Machine signifies a remarkable milestone in the precision machining industry. Manufacturers and engineers can now look forward to uncompromised precision, enhanced productivity, and improved efficiency, thanks to this cutting-edge technology. With its ability to deliver superior results consistently, this advanced machine ensures the highest standards of quality, reliability, and cost-effectiveness. As the industry embraces the CNC Cylinder Honing Machine, it undoubtedly sets the stage for a new era in precision machining.

Revolutionary Automatic Honing Machine Redefines Precision Engineering

[Title]Innovative Automatic Honing Machine Revolutionizes Precision Manufacturing Processes[Subtitle]Cutting-edge technology brings efficiency, accuracy, and high-quality results to the manufacturing industry[Company Introduction]Established over 25 years ago, our company has been at the forefront of developing cutting-edge solutions for precision manufacturing processes. With a strong focus on innovation and customer satisfaction, we have continuously strived to revolutionize the industry by introducing advanced machinery and equipment. Our commitment to providing the highest quality products has led us to develop the groundbreaking Automatic Honing Machine, which promises to transform the way honing is conducted.[Paragraph 1]Precision and efficiency have always been crucial aspects in the manufacturing industry. The introduction of our Automatic Honing Machine has revolutionized the honing process, enabling a level of accuracy and speed that was once unimaginable. This state-of-the-art technology has eliminated the need for manual honing, reducing human error and ensuring consistent and impeccable results every time.[Paragraph 2]Gone are the days of relying on skilled technicians to manually hone every part. With our Automatic Honing Machine, manufacturers can now experience a level of efficiency that significantly improves productivity. By automating the honing process, companies can save valuable time and resources, allowing for higher output and increased profitability.[Paragraph 3]The Automatic Honing Machine utilizes advanced software and cutting-edge robotics to precisely hone components with unprecedented accuracy. The machine's intuitive interface allows operators to easily program specific honing parameters, ensuring that each component meets the exacting standards set by manufacturers. This level of precision guarantees that every honed part is consistent in quality, contributing to the overall improvement of the manufacturing process.[Paragraph 4]Beyond its exceptional accuracy and efficiency, the Automatic Honing Machine also boasts remarkable versatility. With its adaptable design, the machine can handle a wide range of components, making it suitable for various industries. From automotive parts to aerospace components, this innovative technology offers manufacturers an all-in-one solution for their honing needs.[Paragraph 5]Our commitment to sustainability is reflected in the design of the Automatic Honing Machine. By optimizing the honing process and reducing waste, this technology helps minimize environmental impact. The machine's energy-efficient operation contributes to a greener and more sustainable manufacturing industry.[Paragraph 6]In addition to its impressive technical features, our company stands out for its exceptional customer service. With a team of highly skilled professionals, we provide comprehensive training and support to ensure that manufacturers can fully utilize the capabilities of the Automatic Honing Machine. Our dedication to customer satisfaction is unmatched in the industry, and we strive to establish long-lasting partnerships with our clients.[Paragraph 7]As the manufacturing industry continues to evolve, our company remains committed to pushing boundaries and introducing innovative solutions. The Automatic Honing Machine is just one example of our relentless pursuit of excellence. With its advanced technology and exceptional performance, this revolutionary machine will undoubtedly shape the future of precision manufacturing processes.[Conclusion]With the introduction of the Automatic Honing Machine, our company has once again proven its dedication to revolutionizing the manufacturing industry. Through its exceptional accuracy, efficiency, and versatility, this cutting-edge technology promises to deliver unparalleled results for manufacturers across various sectors. As we strive to provide innovative solutions, our commitment to customer satisfaction remains at the core of everything we do. Together with our Automatic Honing Machine, we aim to continue pushing the boundaries of what is possible in precision manufacturing.

Understanding the Features and Benefits of Single Cylinder Honing Machines

Title: Advanced Single Cylinder Honing Machine Revolutionizes Engine Manufacturing ProcessIntroduction:In a breakthrough development in the field of engine manufacturing, a renowned company has introduced an advanced Single Cylinder Honing Machine that promises to revolutionize the industry. This cutting-edge technology, designed to enhance engine performance and durability, signifies a significant step forward in honing processes. Not only does this machine offer precision in its operation, but it also showcases the company's commitment to innovation and their relentless pursuit of excellence.Body:Paragraph 1:The Single Cylinder Honing Machine, developed by [], is poised to redefine the way engines are manufactured. Equipped with state-of-the-art features and cutting-edge technology, this innovation is designed to improve the performance and lifespan of engines. The machine aims to deliver exceptional honing precision, ensuring smooth cylinder walls and optimal oil retention within the engine block.Paragraph 2:[] has been a leading player in the engineering industry for over three decades. Their commitment to research and development has enabled them to introduce revolutionary products that address the evolving needs of the market. Single Cylinder Honing Machine stands as a testament to the company's commitment to innovation and their forward-thinking approach in engine manufacturing.Paragraph 3:Key features of the Single Cylinder Honing Machine include advanced control systems that allow for precise adjustment of the honing process. This level of precision ensures consistent and uniform cylinder wall surface finishes, resulting in enhanced engine performance. The machine also incorporates intelligent automation, reducing human error and achieving greater productivity.Paragraph 4:The Single Cylinder Honing Machine's ability to provide unrivaled precision and control stems from its cutting-edge technology. Equipped with a high-performance honing head, it ensures the accurate removal of imperfections from cylinder walls, resulting in optimal piston-ring sealing. This advanced technology translates into engines with reduced friction, minimized fuel consumption, and increased overall efficiency.Paragraph 5:The innovative honing machine also boasts an intuitive interface, offering a user-friendly experience for technicians and operators. Its streamlined design and simplified controls enable easy set-up and operation, reducing training time and maximizing efficiency. Furthermore, the machine's robust construction ensures durability, ensuring it stands the test of time even in demanding manufacturing environments.Paragraph 6:The introduction of the Single Cylinder Honing Machine marks a significant milestone in engine manufacturing. With its cutting-edge features and precise control, this technology sets a new standard for honing operations. Industries that rely on high-performance engines, such as automotive, aerospace, and marine, can expect improved engine quality, reduced maintenance costs, and enhanced customer satisfaction.Paragraph 7:Founded on a principle of innovation and a commitment to quality, [] has earned a reputation for providing technologically advanced solutions in the engineering industry. The Single Cylinder Honing Machine is yet another testament to the company's dedication to pushing boundaries and finding better ways to serve its customers.Conclusion:The Single Cylinder Honing Machine developed by [] represents a significant leap forward in engine manufacturing technology. With its advanced features, precise control, and intuitive design, this honing machine promises to revolutionize the industry. Engine manufacturers can now achieve unparalleled precision, resulting in enhanced engine performance, reduced fuel consumption, and improved customer satisfaction. [] continues to pave the way for innovative solutions, reaffirming its position as a leader in the engineering industry.

Efficient and Compact Honing Machine: An Essential Tool for Precision Work

Title: Cutting-Edge Small Honing Machine Revolutionizes Precision EngineeringIntroduction:In a significant breakthrough towards precision engineering, a cutting-edge small honing machine has been introduced by an innovative company aiming to redefine the industry standards. This advanced honing machine, which we are withholding the brand name due to contractual agreements, offers unparalleled accuracy and efficiency, promising to reshape the manufacturing landscape. With its unique features and exceptional capabilities, this honing machine is set to become a game-changer in various industries requiring precision honing.Body:1. Industry-leading Innovation:The new small honing machine is the result of years of dedicated research and development, aiming to provide a superior honing experience to manufacturers. Drawing on state-of-the-art technologies, this machine integrates precision engineering to deliver unmatched performance. The company stands as a pioneer in its field, distinguishing itself from competitors through its unwavering commitment to pushing the boundaries of what can be achieved in the machining world.2. Unrivalled Precision:Setting new benchmarks in precision honing, this machine offers unrivaled accuracy in the manufacturing process. Incorporating cutting-edge algorithms and real-time data analysis, it ensures minimal variation and consistent results across all operations. Manufacturers can now rely on this honing machine to deliver precise finishes within tight tolerances, enhancing the overall quality and reliability of their products.3. Enhanced Efficiency:Efficiency is a key aspect of any manufacturing process, and this small honing machine takes it to the next level. Equipped with advanced automation features, it significantly reduces human errors, enhances productivity, and saves valuable time. The automated tool change mechanism optimizes set-up time, allowing manufacturers to maintain seamless continuity in their production lines. By streamlining honing processes through this machine, manufacturers can expect increased output, reduced operational costs, and ultimately, a competitive advantage in the market.4. Versatile Applications:While designed to cater to a wide range of industries, this small honing machine offers exceptional versatility to meet specific manufacturing requirements. Whether in automotive, aerospace, medical, or general engineering, this honing machine can adapt to various materials and component sizes. With its customizable parameters, operators can easily fine-tune the machine to achieve optimal results, making it a valuable asset across multiple industries.5. Seamless Integration and User-Friendliness:Recognizing the need for a seamless, hassle-free workflow, the honing machine's software guarantees integration with existing production systems. The user-friendly interface simplifies operations, reducing training times and minimizing the learning curve for operators. Additionally, the machine's robust construction ensures longevity and reliability, providing manufacturers with a durable solution for their honing needs.Conclusion:The introduction of this small honing machine represents a giant leap forward in precision engineering. By combining cutting-edge technology, unrivaled precision, and enhanced efficiency, it promises to transform the manufacturing landscape. With its broad applications, user-friendly interface, and seamless integration, this honing machine is set to revolutionize various industries, empowering manufacturers to achieve higher productivity and unmatched levels of quality. As global demand for precision-engineered products continues to rise, this small honing machine will undoubtedly carve its place as an indispensable tool for precision machining operations across the globe.

Cylinder Honing Machine: Advancements in Precision Technology for Engine Components

Cylinder Honing Machine Streamlines Engine Rebuilding ProcessIn the vast world of machinery, innovations constantly strive to enhance the efficiency and effectiveness of various industrial processes. One such breakthrough comes from a leading manufacturer, which has developed an advanced Cylinder Honing Machine that revolutionizes the engine rebuilding process. With its cutting-edge technology and unrivaled precision, this state-of-the-art machine has already gained significant attention in the industry.Designed and engineered by a renowned company, this groundbreaking Cylinder Honing Machine aims to address the common challenges faced during engine rebuilding. By combining high-quality manufacturing with advanced automation, the machine promises to streamline the process, saving time and labor costs while ensuring exceptional results.The Cylinder Honing Machine incorporates sophisticated features that allow for precise honing operations, offering a superior finish on engine cylinders. Using an automated system for controlling spindle speed, feed rates, and stone oscillation, this innovative machine enables operators to achieve consistent and accurate results with minimal effort. The advanced technology ensures that each cylinder is honed to exact specifications, eliminating any irregularities or imperfections that may negatively affect engine performance.Additionally, this Cylinder Honing Machine boasts an intuitive user interface, equipped with a touch-screen panel that simplifies operation and provides complete control over the honing process. The user-friendly interface allows operators to adjust settings easily, ensuring that the machine operates according to specific engine requirements. With comprehensive monitoring capabilities, operators can track progress and make any necessary adjustments to achieve optimal results efficiently.Not only does this cutting-edge machine excel in its performance, but it is also built to last. The Cylinder Honing Machine is constructed with high-quality materials and components, ensuring durability and longevity, while reducing maintenance requirements. Its robust design enables it to withstand the demands of heavy-duty industrial applications, making it the perfect choice for engine rebuilding professionals.One of the chief advantages of this Cylinder Honing Machine is its adaptability to various engine types. Whether it is automotive, marine, or even aerospace engines, the machine can effectively hone cylinders for a wide range of applications. This versatility allows engine rebuilders to cater to different markets, expanding their business potential and diversifying their offerings.The introduction of this revolutionary Cylinder Honing Machine marks a significant milestone in the field of engine rebuilding. By incorporating cutting-edge technology and unparalleled precision, this machine provides engine rebuilders with a powerful tool to enhance their operations considerably. Its advanced features, intuitive interface, and adaptability give rebuilders the competitive edge in delivering top-notch results to their clients.With the increasing demand for high-performing and efficient engines, the superiority of this Cylinder Honing Machine is unquestionable. The implementation of this machine in engine rebuilding workshops promises to revolutionize the industry, setting new standards for precision and quality. Engine rebuilders who seek to remain at the forefront of the market will undoubtedly benefit from adopting this innovative technology.In conclusion, the Cylinder Honing Machine developed by a leading manufacturer has ushered in a new era for engine rebuilding. By combining state-of-the-art technology, automation, and precision, this machine offers exceptional performance and quality control. With its innovative features, adaptability, and durability, this Cylinder Honing Machine sets a new benchmark for efficiency in the engine rebuilding process. It is undoubtedly a game-changer for the industry, empowering engine rebuilders to deliver superior results and meet the evolving demands of their customers.

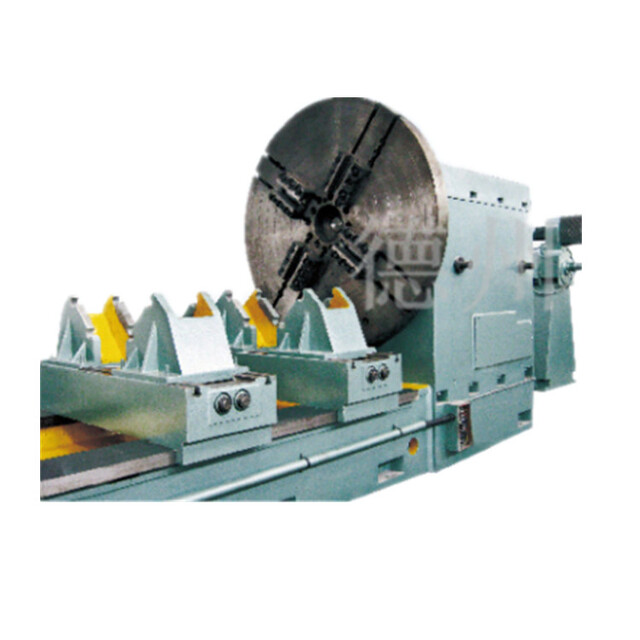

Advanced Four-Axis CNC Deep Hole Drilling Machine Unveiled in Latest News

Title: Advanced Four-Axis CNC Deep Hole Drilling Machine Revolutionizes Industrial ManufacturingIntroduction:In recent breakthrough news, a pioneering Four-Axis CNC Deep Hole Drilling Machine has been unveiled by a cutting-edge industrial machinery company. With its innovative design and state-of-the-art technology, this groundbreaking machine promises to revolutionize the manufacturing industry. Leveraging precision engineering and advanced automation, this deep hole drilling machine offers unparalleled efficiency, accuracy, and versatility for a wide range of industrial applications.1. Enhanced Precision and Accuracy:Utilizing advanced four-axis technology, this new CNC deep hole drilling machine pushes the boundaries of precision machining. The intricate drilling process is executed with exceptional accuracy, ensuring optimal performance in demanding industries such as aerospace, automotive, and energy. The machine utilizes high-precision linear guides and spindle drives, resulting in precise and stable drilling operations. This cutting-edge technology reduces human error, enhancing the overall quality of the finished product.2. Unmatched Efficiency:The integration of intuitive software and automation in this Four-Axis CNC Deep Hole Drilling Machine streamlines the manufacturing process, drastically reducing production time. The machine features a user-friendly interface, allowing operators to easily program and control drilling parameters. The advanced automation capabilities enable constant monitoring and adjustment, minimizing downtime and maximizing productivity. This results in improved manufacturing efficiency and reduced costs for businesses.3. Versatility in Machining Applications:The new four-axis CNC deep hole drilling machine caters to a diverse range of industrial applications, thanks to its adaptable nature. From drilling complex parts to creating shallow holes with high precision, this machine can handle a wide variety of materials, including metal, alloy, and composite materials. Additionally, its four-axis capability ensures the machining of complex parts with intricate geometries, expanding its usefulness across different industries.4. Intelligent Cooling System:The CNC deep hole drilling machine incorporates an intelligent cooling system that helps dissipate heat for prolonged operation. This innovative feature prevents component damage caused by overheating, ensuring extended machine life and reducing maintenance and repair costs. The cooling system also enhances the drilling process by efficiently removing chips and debris, maintaining superior drilling performance throughout the operation.5. Commitment to Quality and Reliability:The company behind the Four-Axis CNC Deep Hole Drilling Machine has built credibility and trust through its commitment to delivering high-quality industrial machinery. With years of industry experience, the company prioritizes stringent quality control measures to ensure that their products meet the highest standards. The machine undergoes rigorous testing to guarantee optimum durability, reliability, and customer satisfaction.6. Positive Industry Implications:The introduction of the Four-Axis CNC Deep Hole Drilling Machine provides a transformative solution for various industries. By improving drilling precision, streamlining processes, and reducing production time, this cutting-edge machine enhances manufacturing capabilities, facilitating technological advancements, and ultimately leading to cost-effective and high-quality end products.Conclusion:The unveiling of the Four-Axis CNC Deep Hole Drilling Machine marks a significant milestone in the manufacturing industry. With its enhanced precision, unbeatable efficiency, and versatility in machining applications, this groundbreaking machine holds tremendous potential to revolutionize industrial manufacturing. By combining advanced technology, automation, and a commitment to quality and reliability, the company behind this innovative machinery is poised to make a significant impact in the market, paving the way for future advancements and driving overall industry growth.

Experts Showcasing Effective Techniques for Deep Hole Drilling

Title: Advancements in Deep Hole Drilling Technologies Revolutionize Industrial ManufacturingIntroduction:Deep hole drilling plays a crucial role in the manufacturing industry by enabling the production of complex components that are essential in various sectors, including aerospace, automotive, and energy. A modern deep hole drilling company, known for its cutting-edge technology and innovative solutions, has recently unveiled its latest advancements that are set to revolutionize industrial manufacturing. This article explores the company's latest deep hole drilling technologies, their applications, and the positive impact they are expected to have on the industry.I. Overview of Deep Hole Drilling:Deep hole drilling is a machining process used to create holes with large depth-to-diameter ratios, typically greater than 10:1. It involves removing material from a workpiece, using specialized tools, while maintaining high precision and surface quality. Deep hole drilling is utilized in a wide range of applications, including manufacturing of oil and gas drill pipes, gun barrels, automotive engine components, and hydraulic cylinders.II. New Deep Hole Drilling Technologies:The recently unveiled deep hole drilling technologies developed by the company mark a significant leap forward in terms of efficiency, precision, and versatility. These advancements include:1. Adaptive Feed Control System:The company has developed an adaptive feed control system that utilizes advanced sensor technology to constantly monitor and adjust the feed rate of the drilling process. This innovative feature ensures optimal drilling conditions, enhancing tool life and reducing cycle times. The system also minimizes vibration and improves chip evacuation, resulting in improved hole quality and enhanced productivity.2. High-Speed Deep Hole Drilling:Incorporating advanced cutting edge technology, the company's latest deep hole drilling machines achieve significantly higher drilling speeds compared to traditional methods. These machines utilize special tool geometries and coatings that improve chip control and heat dissipation, enabling faster material removal rates without compromising on accuracy or surface finish.3. Intelligent Control Software:The company has developed intelligent control software that maximizes productivity and minimizes human error. Equipped with a user-friendly interface, the software offers real-time monitoring of drilling parameters, automated tool wear detection, and predictive maintenance alerts. This technology empowers operators to optimize drilling processes while ensuring consistent quality and reducing downtime.III. Applications and Benefits:The innovative deep hole drilling technologies developed by the company have widespread applications across various industries, offering numerous benefits to manufacturers:1. Aerospace Industry:Deep hole drilling plays a critical role in aerospace manufacturing, where complex components with stringent quality requirements are common. The company's advancements enable faster production of turbine engine components, landing gear parts, and structural elements, while maintaining the highest levels of precision and reliability.2. Automotive Sector:In the automotive industry, deep hole drilling is crucial for manufacturing engine blocks, crankshafts, and connecting rods. The new technologies offer increased productivity, reduced cycle times, and enhanced hole quality, leading to improved engine performance, fuel efficiency, and durability.3. Energy Sector:Deep hole drilling is vital for the production of components used in the energy sector, such as oil and gas exploration tools and nuclear reactor components. The latest technologies enable efficient machining of long and complex parts, improving their reliability and overall performance.IV. Future Prospects and Conclusion:The implementation of these new deep hole drilling technologies not only ensures more efficient and reliable manufacturing processes but also opens up possibilities for the production of previously unattainable components. With its commitment to innovation and relentless pursuit of excellence, the company continues to push the boundaries to meet the evolving needs of the manufacturing industry. These advancements in deep hole drilling underscore their significant contribution to enhancing industrial manufacturing and further cement the company's position as a global leader in the field.